Thursday, 6 Nov 2025

|Cold Chain Excellence in 2025: AI Agents for Pharma, Food, and Perishables with Predictive Quality Management

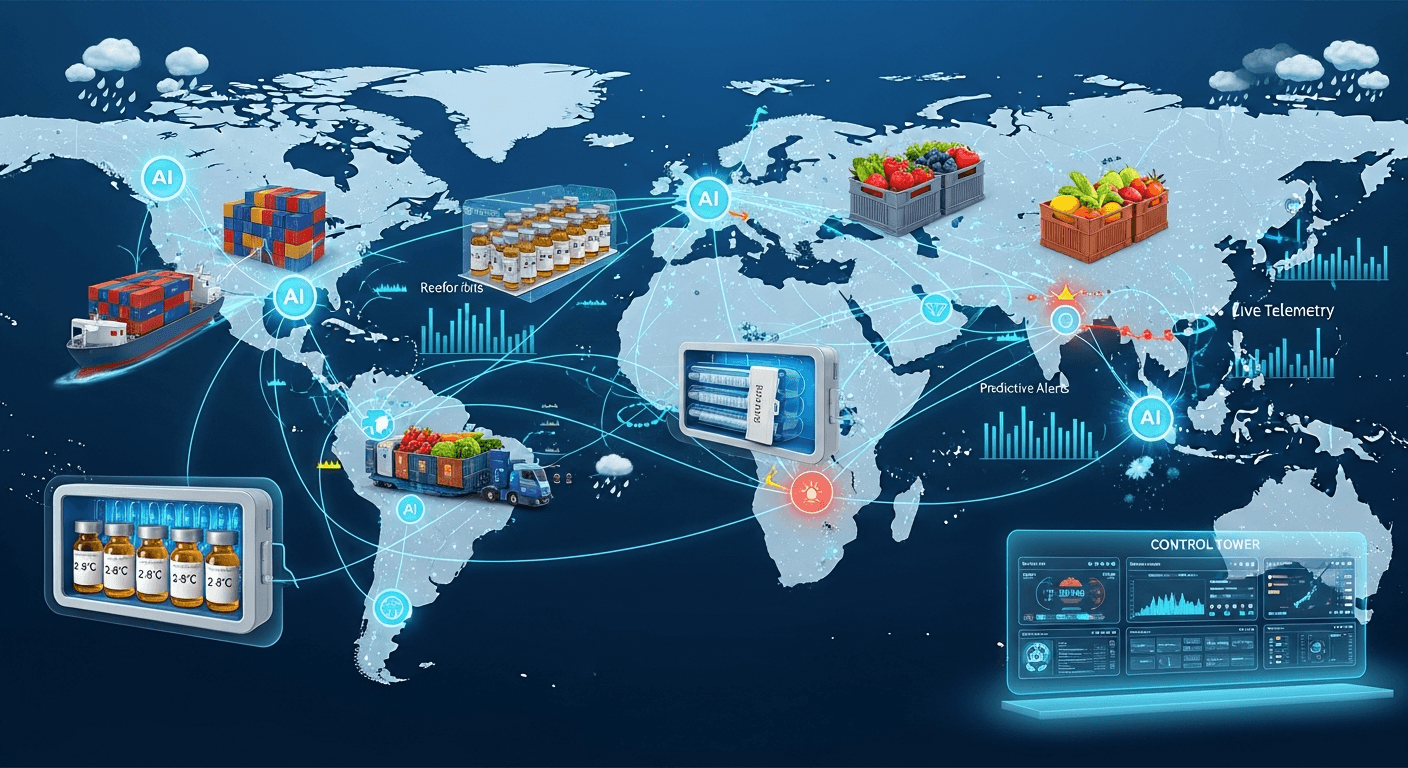

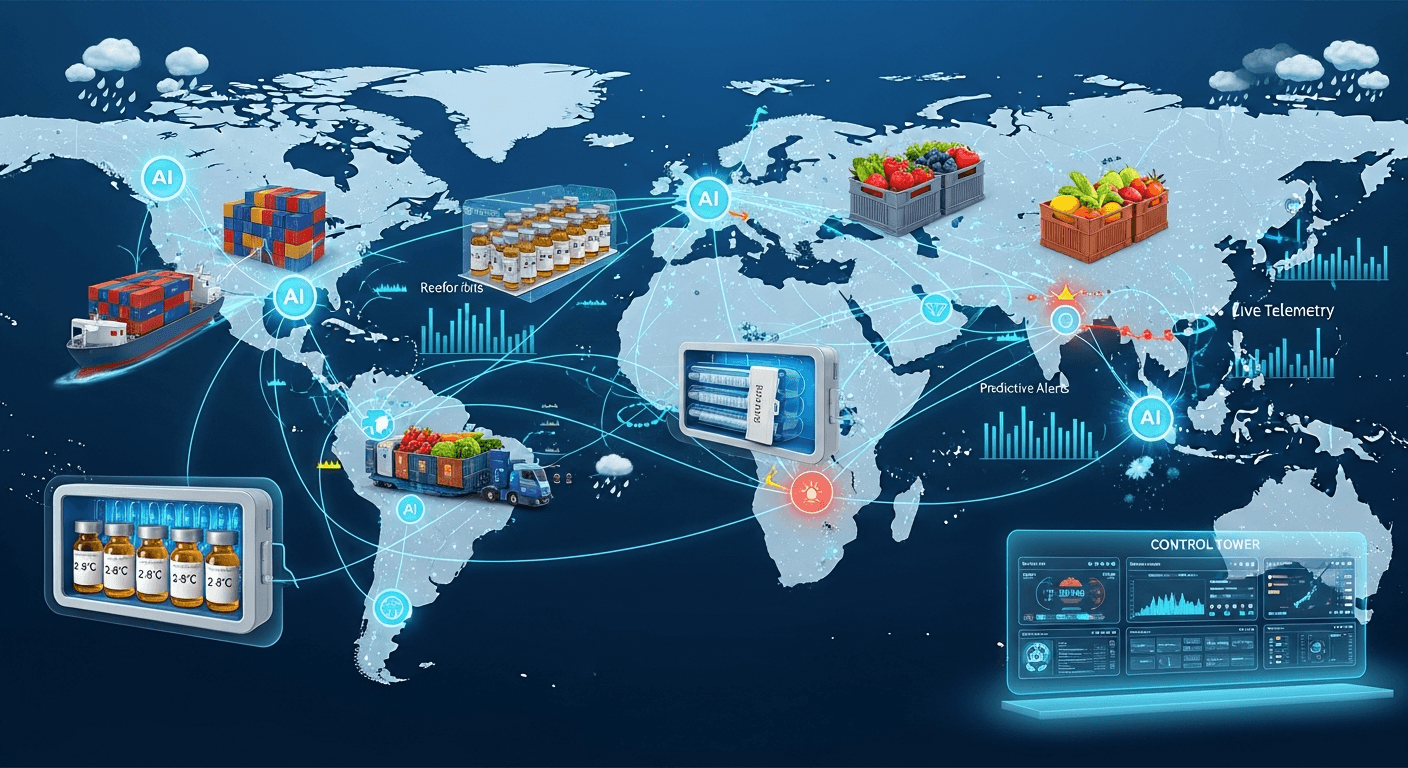

AI agents now safeguard temperature-sensitive logistics end to end by predicting excursions before they occur, orchestrating rapid interventions across fleets, and providing board-grade traceability that reduces spoilage and compliance risk at scale. In cold chains for pharmaceuticals, food, and perishables, this shift from reactive alarms to predictive quality management cuts waste, improves OTIF, and protects brands in a market expanding rapidly through 2025 and beyond.

Introduction

Cold chain failures remain a hidden drag on profitability and public health, with industry estimates citing tens of billions of dollars lost annually and excursion rates that can invalidate entire shipments within minutes. As biologics, fresh foods, and high-value perishables surge in volume and regulatory scrutiny tightens, AI-driven agents paired with IoT telemetry and predictive analytics have become essential to assure quality, compliance, and cost control at scale. This article presents specialized applications for pharmaceuticals, food, and perishables, explains predictive quality management patterns, and offers an executive playbook to scale AI agents across cold chains with measurable ROI and lower risk.

Why AI agents for cold chain

Cold chain networks are complex socio-technical systems spanning reefer equipment, multi-modal routes, cross-dock nodes, and regulatory checkpoints where small temperature deviations cause outsized loss. AI agents provide continuous sense—think—act loops: they fuse sensor streams, forecast excursions, propose corrective actions, and coordinate stakeholders under governance constraints. These loops turn fragmented monitoring into proactive quality assurance with audit trails suitable for regulators and customers alike.

The business case in 2025

Global cold chain markets exceed hundreds of billions in 2025, with rapid growth fueled by pharmaceuticals and fresh food demand, placing premium on integrity, visibility, and energy efficiency. ABI Research data shows executives are prioritizing AI and agentic automation across forecasting, rerouting, and supplier orchestration, indicating readiness for scaled deployments rather than isolated pilots. Track-and-trace revenues within pharma alone are projected to rise markedly by mid-decade, reflecting investment in serialized, condition-aware logistics and compliance-grade telemetry.

The cost of failure

Pharma temperature-related losses are estimated between $20–35 billion annually, with up to 50% of vaccines discarded globally due to cold chain excursions in some contexts, highlighting an urgent quality gap. Beyond direct write-offs, excursion events trigger recalls, regulatory findings, and reputational damage that depress lifetime revenues for brands and therapies. For food, excursions and humidity variance degrade shelf-life and sensory quality, increasing shrink and returns even when products remain saleable on paper.

Architecture: agentic cold chain

Core components

- Edge sensing and telemetry: temperature, humidity, vibration, door events, geolocation, and power cycles from reefers, containers, trailers, and facilities streaming at sub-minute intervals.

- Data platform and digital twins: consolidates telemetry, shipment context, and SOPs to simulate thermal behavior and predict excursion risk windows on each lane and asset.

- Agentic layer: specialized agents for excursion prediction, remediation planning, route/risk re-optimization, CAPA initiation, and regulatory documentation generation with human-in-the-loop.

- Governance and compliance: policy engines encode WHO GDP, FDA/EMA expectations, and customer SLAs, enforcing validated ranges, calibration requirements, and audit trails.

This stack enables near-real-time decisions while preserving explainability and documentation critical to audits and Qualified Person release processes.

Predictive quality management

Predictive models estimate excursion probability given current telemetry, lane weather, dwell forecasts, and asset health, enabling preventative actions before thresholds are breached. Actions include micro-route adjustments, dwell avoidance at hot spots, dynamic setpoint tuning, backup power engagement, and pre-authorized transloads within validated windows. Post-event, agents trigger CAPA workflows with root-cause analysis tied to sensor histories, asset diagnostics, and SOP deviations, improving systemic resilience over time.

Pharmaceuticals: ultra-high assurance

Requirements and risks

Pharma shipments often require 2–8°C, CRT, or deep-frozen ranges with documented lane validation, sensor calibration, and chain-of-custody audits across partners. Excursions—even 1–2°C—can compromise potency for biologics and vaccines, and the share of temperature-dependent top-sellers makes cold chain a board-level priority. Regulators expect robust deviation management and traceability, pushing investment into serialized, condition-aware logistics and release-by-exception protocols.

Agent applications

- Release-by-exception: agents collate telemetry, calibration certificates, and lane SOPs to certify compliance or flag deviations for QP review, accelerating release while retaining rigor.

- Excursion prediction and avoidance: agents forecast risk windows hours ahead, orchestrating route or dwell adjustments to maintain thermal integrity and minimize costly pack-out overages.

- Asset health and RCM: predictive maintenance for reefers and containers detects failing compressors, low refrigerant, or battery degradation before they cause spoilage.

- Recall and returns triage: agents evaluate temperature profiles against stability data to segregate salvageable stock from waste, reducing over-disposal and speeding corrective actions.

Pharma ROI stems from avoided write-offs, faster release, reduced lane validation rework, and lower insurance and compliance costs.

Food and perishables: freshness economics

Demand dynamics

Rising e-grocery and fresh categories intensify quality and shelf-life pressures while consumers and retailers expect transparent provenance and sustainability. Temperature, humidity, and ethylene exposure drive ripening and spoilage rates, making predictive handling a lever on shrink and service levels.

Agent applications

- Ripeness-aware orchestration: agents match lots to destinations based on remaining shelf-life, demand, and transit risk to maximize sell-through and reduce markdowns.

- Micro-fulfillment routing: dynamic routing avoids heat islands and congestion to preserve cold chain continuity in last mile during peak and extreme weather events.

- Store/DC operations: agents adjust setpoints, door policies, and loading sequences based on predicted thermal drift and workload, cutting energy use without compromising quality.

- Claims automation: condition-based evidence packages reduce disputes with carriers and vendors, shortening recovery cycles and improving partner trust.

This translates to lower shrink, better OTIF, fewer returns, and improved customer experience on freshness-sensitive SKUs.

Cross-industry enablers

Telemetry and connectivity

Widespread use of low-cost trackers and containerized IoT platforms enables lane-by-lane risk modeling and real-time exception handling across carriers. Maersk and other ocean carriers deploy remote container management to provide temperature, humidity, and CO2 visibility, unlocking predictive maintenance and proactive interventions.

Sustainability and energy

Agentic optimization reduces miles, idling, and thermal leakage, delivering dual benefits in fuel/energy cost and emissions reductions aligned to ESG targets. Electrification and smarter compressors paired with AI control loops further stabilize temperatures while lowering total cost of ownership in reefer fleets and facilities.

Operating model and governance

Human-in-the-loop

While agents propose and implement routine actions, critical deviations and high-value shipments route to trained operators with clear decision rights and escalation paths. This hybrid model balances speed with accountability, improving outcomes without losing GMP/GDP compliance and auditability.

KPIs and ROI

Executives should track excursion rate, temperature-at-risk time, salvage rate post-deviation, release cycle time, and condition-based claim recoveries as leading indicators. Financially, avoided spoilage, reduced write-offs, fewer expedited shipments, energy savings, and insurance premium improvements drive the business case in months, not years.

Implementation blueprint

Phase 1: Instrument and baseline

Deploy calibrated sensors on priority lanes and assets, integrate telemetry with shipment context, and establish a quality data lake with validation rules and audit trails. Baseline excursion frequency and time-above-threshold by lane, asset type, and node to target the highest-return interventions first.

Phase 2: Predict and prevent

Introduce excursion prediction and asset-health agents with conservative thresholds and human approvals, focusing on high-value therapies and short-shelf-life foods. Stand up playbooks for rerouting, transload, and controlled disposal that agents can trigger and document under SOPs.

Phase 3: Scale and automate

Expand to network-wide orchestration, enable release-by-exception for compliant shipments, and automate CAPA initiation with root-cause analytics feeding continuous improvement. Integrate with TMS/WMS and partner portals to coordinate actions across carriers and nodes with shared context and guardrails.

Case highlights from leaders

- DHL and Walmart apply IoT-driven monitoring and route optimization to maintain product integrity, demonstrating measurable reductions in spoilage and delivery times.

- Maersk uses remote container management and predictive maintenance to safeguard reefer cargo, reducing failure risk and enabling proactive service actions in transit.

- ABI Research reports strong executive momentum for AI and agentic automation across supply chains, reinforcing the shift from pilots to scaled decision autonomy.

Risk, compliance, and trust

Excursions must be managed under documented GDP/GMP and food safety frameworks, with agents generating compliant evidence sets and maintaining calibration lineage for sensors. Privacy and third-party risk assessments are essential when sharing telemetry across ecosystems, requiring robust access controls and vendor oversight. Transparent explainability and event logs improve insurer and regulator confidence, accelerating claims and reducing audit friction.

Future outlook

As climate volatility increases, AI agents will incorporate hyperlocal weather nowcasts and infrastructure stress models to anticipate risk hours ahead, not minutes. Digital twins of lanes and assets will enable scenario testing for pack-out configurations, energy setpoints, and handoff timing to engineer resilience into network design. Over time, fully autonomous corrective loops will handle routine deviations while humans focus on policy, exceptions, and continuous improvement.

Call to Action

See how agentic cold chain orchestration can cut spoilage, accelerate release, and simplify audits across your network—book a personalized demo to get a tailored ROI and risk plan. Schedule a Demo

Conclusion

AI agents convert cold chains from brittle, alarm-heavy systems into proactive quality engines that protect patient safety, food freshness, and brand trust while reducing waste and cost. With predictive quality management, release-by-exception, and asset-health orchestration, logistics leaders can scale assurance across lanes and partners with governance that satisfies regulators and insurers.

Organizations that move now will capture outsized returns as market growth and climate-driven risks intensify, using agentic AI to deliver measurable resilience and service differentiation. The next wave of cold chain excellence belongs to networks that think ahead, act fast, and document everything with board-grade rigor.

All blog posts

View All →

Friday, 7 Nov 2025

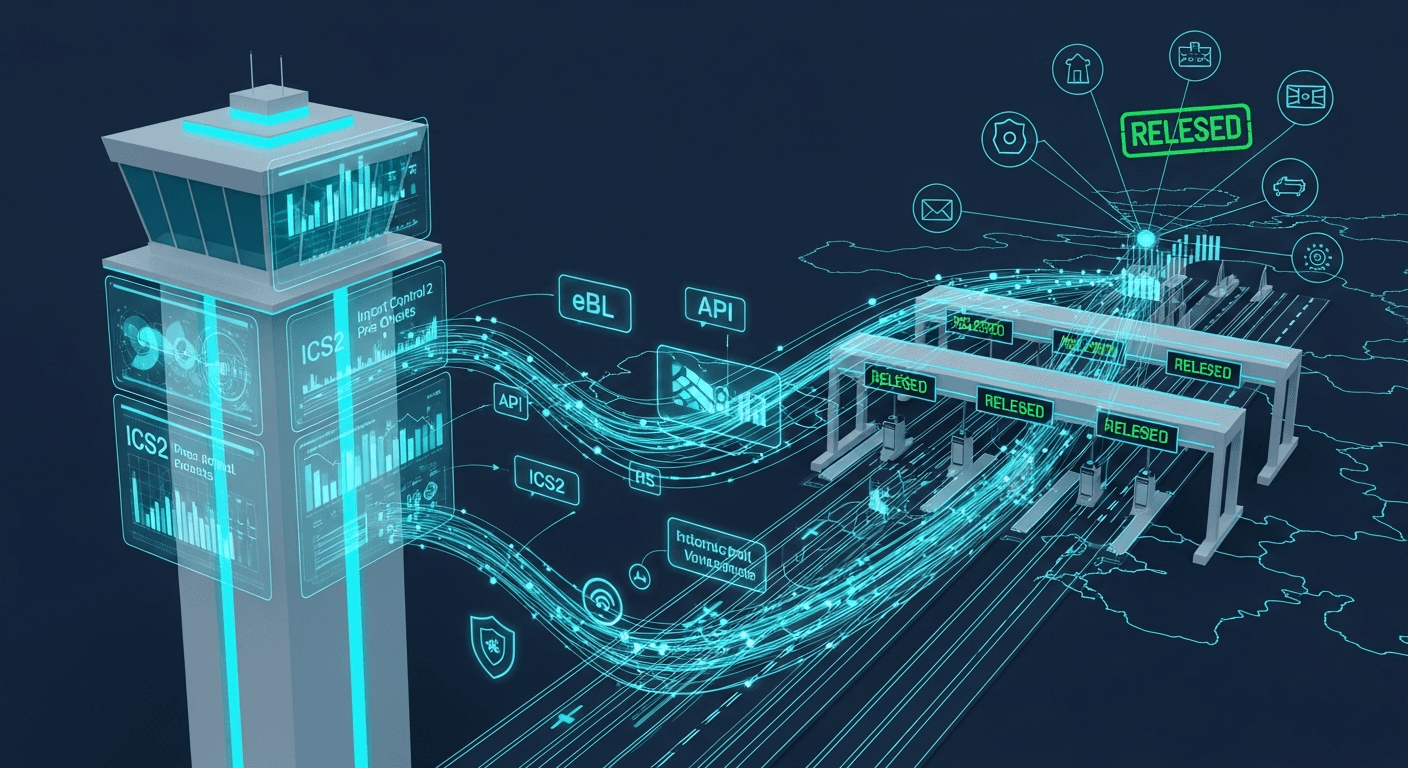

Cross-Border Trade Automation in 2025: AI for Customs, HS Classification, and e-Documentation at Scale.

Automate customs with AI: HS code classification, eBL, and ICS2-ready filings to cut delays, errors, and costs in global shipping.

Thursday, 6 Nov 2025

Cold Chain Excellence in 2025: AI Agents for Pharma, Food, and Perishables with Predictive Quality Management

Scale cold chain quality with AI agents across pharma, food, and perishables—predict excursions, cut spoilage, and meet compliance with proactive, auditable control.

Tuesday, 4 Nov 2025

Stakeholder Alignment for AI Investments in Logistics 2025: ROI and Risk Frameworks that Win Approval

Win board confidence for AI in logistics in 2025 with ROI narratives, risk controls, and case studies from UPS, DHL, Amazon, Walmart, and Maersk. Tags