AI Demand Forecasting for Logistics Executives: ROI Guide

Tuesday, 7 Oct 2025

|

The Executive's AI Advantage: How Intelligent Demand Forecasting Transforms Supply Chain Performance

The global logistics industry faces an unprecedented challenge: demand volatility that traditional forecasting methods simply cannot handle. For logistics executives, the question isn't whether to adopt AI-driven demand forecasting—it's how quickly you can implement it to stay competitive.

McKinsey's latest research reveals that organizations implementing AI-enhanced forecasting reduce supply chain errors by 30-50%, decrease lost sales by up to 65%, and cut warehousing costs by 5-10%. More importantly, these improvements translate directly to your bottom line, with companies reporting revenue growth 61% greater than their peers.

The C-Suite Wake-Up Call: Why Now?

Traditional forecasting is failing your operations. The pandemic, geopolitical tensions, and rapidly changing consumer behaviors have exposed critical weaknesses in conventional demand planning approaches. While your competitors struggle with the same Excel-based forecasting methods from decades past, AI-powered systems are analyzing millions of data points in real-time to predict demand patterns with unprecedented accuracy.

Supply chain leaders consistently identify geopolitical risks (61%) and global trade tensions (58%) as their top challenges for 2025. Yet those who've invested in AI forecasting capabilities are transforming these disruptions into competitive advantages.

Fortune 500 companies are already experiencing the transformation. Amazon processes price adjustments on millions of products daily using predictive algorithms—some products are adjusted up to 10 times in 24 hours. Walmart leverages AI to anticipate emergency supply demand during hurricane season, preemptively stocking affected areas while avoiding overstock elsewhere. These aren't isolated experiments; they're systematic competitive advantages built on intelligent demand forecasting.

The Science Behind Superior Performance

Beyond Historical Data: Multi-Dimensional Intelligence

Traditional demand forecasting relies heavily on historical sales data—a reactive approach that's inherently limited. AI-driven systems integrate diverse data sources including social media sentiment, weather patterns, economic indicators, and competitive intelligence to create comprehensive demand predictions.

Real-time responsiveness sets AI apart from conventional methods. While traditional forecasting updates monthly or quarterly, AI systems continuously analyze streaming data from point-of-sale systems, social media, and market signals to adjust predictions in real-time. This agility enables your organization to respond to demand shifts weeks or months before they impact operations.

Machine Learning Sophistication

Advanced AI forecasting employs multiple algorithmic approaches simultaneously. Long Short-Term Memory (LSTM) networks excel at capturing seasonal patterns and long-term trends, while ensemble models combine predictions from various algorithms to optimize accuracy. These systems identify complex relationships that human analysts miss entirely—such as correlations between local weather patterns and product demand across different geographic regions.

Continuous improvement differentiates AI from static forecasting models. Machine learning algorithms become more accurate over time as they process new data, automatically adjusting to changing market conditions without manual intervention. This self-optimizing capability ensures your forecasting accuracy improves continuously.

Quantifying Executive Impact: Real Numbers

Operational Excellence Metrics

Organizations implementing AI demand forecasting report measurable improvements across key performance indicators:

Inventory Optimization: Companies achieve 20-50% inventory reductions while maintaining service levels. This translates to millions in freed capital for large logistics operations.

Forecast Accuracy: AI systems reduce forecasting errors by 30-50% compared to traditional methods. For a billion-dollar logistics operation, this improvement can save tens of millions annually in inventory carrying costs and stockout penalties.

Supply Chain Efficiency: How AI improves speed and efficiency throughout the supply chain demonstrates how intelligent forecasting enables 35% reductions in inventory levels while boosting service levels by 65%.

Cost Structure Improvements: Leading implementations show 15% reductions in overall logistics costs through optimized inventory positioning and reduced emergency shipments.

Strategic Business Value

Revenue Protection: Accurate demand forecasting prevents stockouts that cost businesses significantly in lost sales. AI systems reduce out-of-stock situations by up to 65%, directly protecting revenue streams.

Cash Flow Optimization: Improved inventory management frees substantial working capital. What is the typical ROI for AI projects in logistics shows how intelligent forecasting delivers measurable financial returns within months of implementation.

Risk Mitigation: AI-powered forecasting provides early warning systems for supply chain disruptions, enabling proactive responses that protect operations and customer relationships.

Strategic Implementation: Your Executive Roadmap

Phase 1: Foundation Building (4-6 weeks)

Data Infrastructure Assessment forms the cornerstone of successful AI implementation. Evaluate your current data quality, accessibility, and integration capabilities. Most organizations discover they have more usable data than initially assumed—the key is organizing and standardizing it effectively.

Pilot Program Definition should focus on high-impact, measurable use cases. Start with product categories that represent significant revenue or operational complexity. Set clear success metrics including forecast accuracy improvements and inventory optimization targets.

Executive Sponsorship proves critical for overcoming organizational resistance. Designate a C-level champion who can drive cross-functional cooperation and resource allocation decisions.

Phase 2: Proof of Value (8-12 weeks)

Model Development and Training using your prepared datasets. Modern AI platforms can achieve meaningful accuracy improvements within weeks, not months. Focus on models that can demonstrate clear business value quickly.

Integration Planning with existing ERP and planning systems ensures seamless operational adoption. Plan for API connectivity and automated data flows that eliminate manual intervention.

Change Management preparation addresses the human element of AI adoption. Train your planning teams on interpreting AI insights and making decisions with machine-augmented intelligence.

Phase 3: Scale and Optimize (12-20 weeks)

Full Production Deployment across your complete product portfolio and geographic regions. Implement automated retraining pipelines that keep models current with changing market conditions.

Advanced Capabilities Integration including external data sources, promotional impact modeling, and supply chain optimization. These enhancements typically deliver additional 10-15% accuracy improvements.

Performance Monitoring Systems ensure sustained value delivery. Establish KPIs for forecast accuracy, inventory performance, and business impact measurement.

Overcoming Executive Concerns

Implementation Complexity

Modern AI platforms have dramatically simplified deployment complexity. No-code solutions enable rapid implementation without extensive technical teams. Cloud-based platforms eliminate infrastructure concerns while providing scalable computing resources.

Realistic timelines for meaningful results range from 4-6 weeks for initial proof-of-concept to 6-9 months for full enterprise deployment. These timelines are significantly shorter than traditional ERP implementations while delivering measurable value much faster.

Cost Justification

Investment ranges vary by scope and complexity. Pilot programs typically cost $16,000-$24,000, while comprehensive enterprise implementations range from $90,000-$190,000. However, the ROI calculation is compelling: organizations commonly achieve payback within 6-12 months through inventory optimization and improved service levels.

Opportunity cost of inaction increasingly outweighs implementation investment. As competitors adopt AI capabilities, the performance gap widens rapidly. Early adopters establish sustainable competitive advantages that become difficult to overcome.

Organizational Readiness

Skills gap concerns are addressable through modern AI platforms that require minimal data science expertise for operation. Focus on training your existing planning professionals to interpret and act on AI insights rather than building technical AI teams from scratch.

Change management success depends on demonstrating clear value to frontline users. AI systems that obviously improve decision-making quality and reduce manual workload gain rapid adoption.

The Competitive Imperative

Market Leadership Trends

Industry leaders are accelerating AI adoption. Recent surveys show 91% of logistics companies increased AI investments over the past 24 months, with predictive analytics and demand forecasting as top priorities. Organizations that delay implementation risk permanent competitive disadvantage.

Technology maturity has reached the point where AI demand forecasting delivers reliable business value rather than experimental results. The question for executives isn't whether the technology works—it's how quickly you can capture its benefits.

Future-Proofing Operations

Autonomous supply chains represent the inevitable evolution of logistics operations. AI-driven demand forecasting provides the foundation for broader automation initiatives including dynamic inventory management, automated procurement, and self-optimizing distribution networks.

Customer expectations continue escalating for faster, more reliable service. AI-powered forecasting enables the service level consistency that modern customers demand while maintaining operational efficiency.

Executive Action Framework

Immediate Steps (Next 30 Days)

Conduct data readiness assessment to understand your current capabilities and gaps. Most organizations can begin AI pilots with existing data sources after basic cleanup and organization.

Identify pilot use cases that offer clear measurable value. Focus on product categories or customer segments where improved forecasting would have obvious business impact.

Engage solution providers to understand implementation options and timelines. Book a demo to explore how AI demand forecasting can transform your operations.

Strategic Planning (Next 90 Days)

Develop implementation roadmap with clear milestones and success metrics. Plan for gradual expansion from pilot to full deployment based on demonstrated results.

Secure organizational buy-in through executive education and stakeholder alignment. Build coalition of supporters across planning, operations, and IT functions.

Resource allocation planning including budget approval and team assignments. Most successful implementations require dedicated project management but leverage existing domain expertise.

Operational Excellence (Next 12 Months)

Deploy and scale AI capabilities across your operations systematically. Focus on sustainable value delivery rather than rapid deployment that sacrifices quality.

Build organizational AI competency through training and process development. Create internal expertise that can extend AI capabilities beyond initial implementations.

Measure and optimize performance continuously. Establish feedback loops that drive ongoing improvement in both AI model performance and business value delivery.

The Executive Decision

The evidence is clear: AI-driven demand forecasting delivers measurable business value for logistics operations. Organizations that act decisively gain sustainable competitive advantages through superior operational performance and customer service.

The cost of inaction exceeds the investment in action. While you deliberate, competitors are capturing market share through superior demand prediction and operational efficiency. The window for gaining first-mover advantage is closing rapidly.

Success requires executive leadership. AI transformation isn't a technology project—it's a business strategy that requires C-level vision, commitment, and drive. Organizations with strong executive sponsorship achieve significantly better results than those treating AI as an IT initiative.

Your supply chain performance depends on demand forecasting accuracy. Traditional methods are failing in today's volatile environment. AI provides the intelligence needed to navigate uncertainty and deliver consistent results.

The question isn't whether AI-driven demand forecasting will transform logistics—it's whether your organization will lead or follow this transformation.

All blog posts

View All →

Monday, 1 Dec 2025

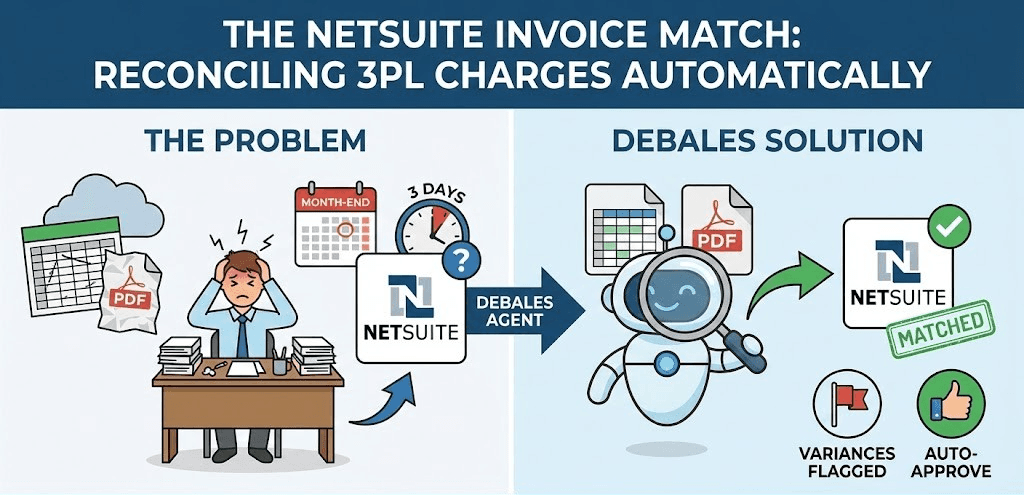

NetSuite 3PL Billing Automation: Catch Pricing Errors Instantly

3PL sends messy spreadsheets/PDF invoices monthly. Accounting wastes 3 days matching against NetSuite. Debales agent auto-reconciles line-by-line, flags pricing errors, and approves matches instantly.

Sunday, 30 Nov 2025

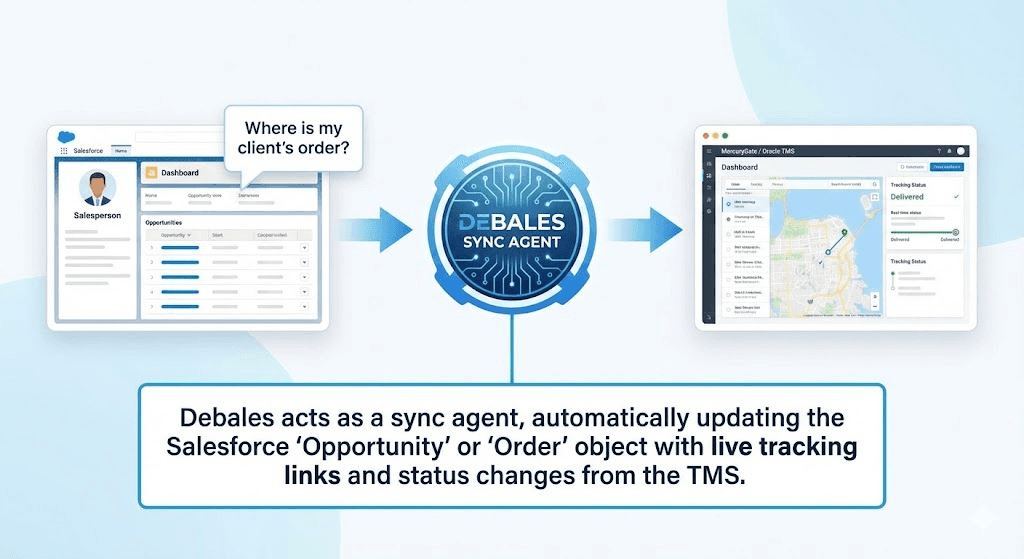

Live Shipment Status in Salesforce: MercuryGate/Oracle TMS Sync

Sales reps ping ops via Slack for shipment status because Salesforce lacks live TMS data from MercuryGate/Oracle. Debales syncs tracking links and status directly to Opportunity/Order objects automatically.

Saturday, 29 Nov 2025

Fixing Inventory Sync Lag Between Shopify and Legacy WMS

Oversold inventory from Shopify and legacy WMS sync lag costs sales and customers. Learn how Debales AI bridges these with real-time order-driven inventory reservation to prevent stockouts.