AI vs Traditional Methods: Answering Your Logistics Automation FAQs

Wednesday, 17 Sep 2025

|

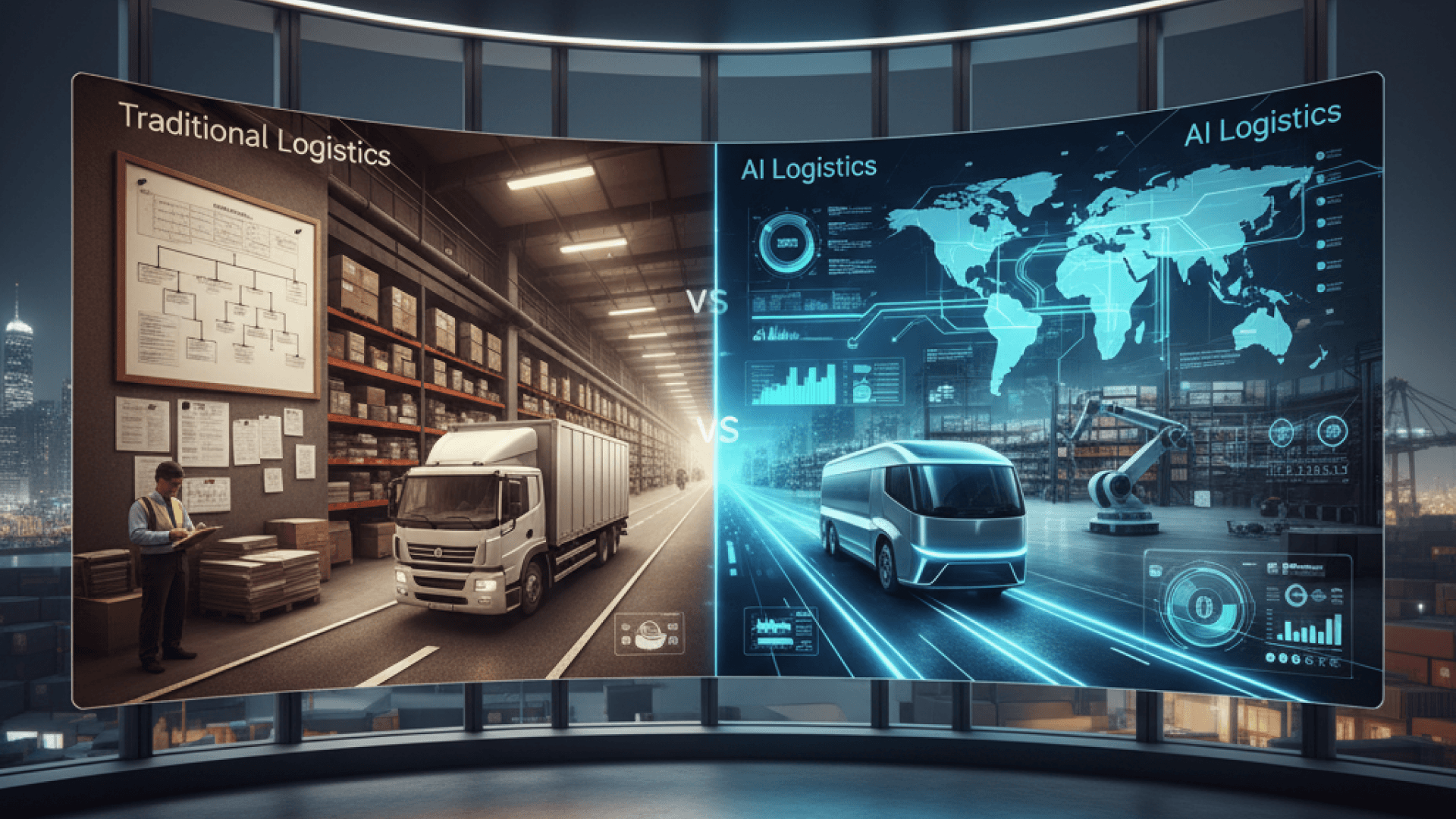

Logistics companies are faced with a key question in 2025: Should you automate with AI or stick with traditional methods? The answer depends on your specific needs, but real-world comparisons reveal significant differences in efficiency, adaptability, and long-term results. Here are the most frequently asked questions—and practical answers—about logistics automation.

Frequently Asked Questions: AI vs Traditional Logistics Methods

1. What’s the main difference between AI and traditional automation?

Traditional systems follow fixed rules and schedules. AI adapts in real time, learning from patterns in data, adjusting to variables like demand shifts, traffic, or equipment status for smarter outcomes.

2. Is AI really more cost-effective?

Studies comparing over 500 warehouses found AI-powered slotting and picking dropped labor costs by 23% and shipping errors by 41%—with 15-30% improved picker travel times—versus static, manual approaches.

3. Can AI reduce supply chain disruptions?

Yes. AI systems continuously analyze millions of data points from IoT sensors, weather feeds, and shipping data, predicting and preventing failures before they occur—reducing monthly breakdowns by up to 72% in recent case studies.

4. What about learning curves and updates?

Traditional systems stay the same unless manually changed. AI algorithms get smarter with each new data cycle, optimizing operations without constant engineering. Seasonal inventory waste dropped from 30% with manual methods to under 10% using AI forecasts.

5. Does AI help with workforce management?

AI job optimization boosted task efficiency by 58% and reduced labor hours in fulfillment centers by almost 40% in under two weeks. It predicts staffing needs, minimizing overstaffing and bottlenecks.

6. Is AI only for large or high-tech logistics companies?

AI tools are now tailored for small and midsize operations too—see our comparison of No-Code AI Solutions (Blog 9) for democratizing automation across company sizes.

7. Are there risks or barriers to AI adoption?

High initial costs, workforce skill gaps, and data integration remain challenges as outlined in 10 Questions Every Logistics Manager Should Ask. Ethical governance and transparency are essential explored further in AI Ethics in Logistics.

8. How does AI improve inventory management and demand forecasting?

AI enables 20–30% higher demand forecasting accuracy and 30% reduced inventory—all while minimizing stockouts and waste, powered by real-time analytics.

9. Can AI-powered automation handle exceptions?

Modern AI systems are designed to involve human oversight for complex, sensitive decisions—see how Human-AI Collaboration balances accountability.

10. What’s the long-term impact of moving to AI?

Early adopters gain resilience, responsiveness, and lower costs—AI adoption is now transitioning from competitive advantage to operational necessity.

For further side-by-side comparisons between automation strategies, explore hands-on implementations in Computer Vision in Warehouse Operations, and see practical scaling advice in From Pilot to Production (Blog 15).

Ready to Compare Logistics Automation Strategies?

The evidence shows that AI-driven logistics delivers measurable returns, agility, and resilience. Book a demo with Debales.ai today to see how the right automation approach can fit your business needs and deliver bottom-line impact.

All blog posts

View All →

Saturday, 28 Feb 2026

Why freight exceptions keep blindsiding your team

Freight exceptions keep surfacing too late, driving detention and accessorials. Learn why it repeats and what ops teams can fix this week.

Saturday, 28 Feb 2026

Why accessorial charges keep wrecking freight budgets

Accessorial charges like detention and reclass keep inflating freight bills. Learn why they happen, how to prevent them, and what to fix this week.

Saturday, 28 Feb 2026

Why freight exceptions keep winning (and how to stop it)

Late loads, detention, and accessorial surprises are usually process failures, not bad luck. Fix the exception loop with cleaner data and faster triage.