Fixing Data Bottlenecks in 3PL Freight Ops

Thursday, 5 Feb 2026

|

Fixing Data Bottlenecks in 3PL Freight Ops

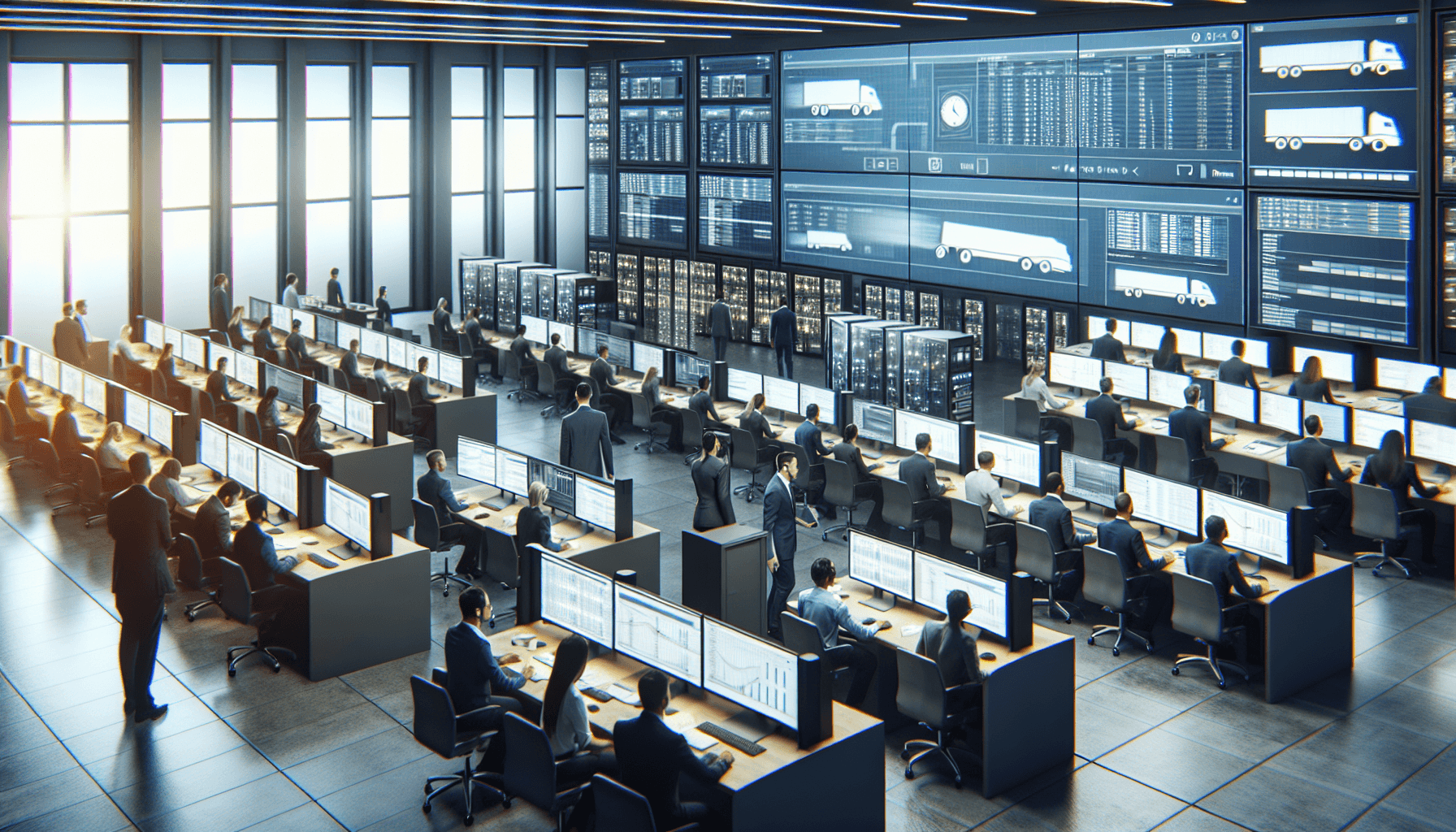

Too Much Freight Data, Not Enough Clarity

If you're a logistics operations lead at a 3PL or managing a brokerage team, here's a daunting number: 72% of transportation professionals say poor data visibility directly causes missed delivery windows. That's nearly three out of four missed shipments that could have been avoided with better data flow.

Daily, you're flooded with disconnected updates from TMS, WMS, emails buried with attachments, incomplete BOLs, and manual check calls. When your team is chasing answers through spreadsheets instead of calling out exceptions or optimizing lanes, it's a clear sign: you've got a data bottleneck problem.

What’s Broken: Fragmented, Delayed, Manual

The freight industry has always dealt with complexity, but complexity without real-time coordination becomes chaos. The problem? Most 3PLs and brokers are still working with:

- Siloed systems between TMS, ERP, and customer portals

- Delayed status updates from carriers

- Manually entered BOL data and load details

- Reactive communication loops that only get triggered after something goes wrong

This adds friction at every operational level - from dispatchers needing faster lane decisions to carrier reps scrambling to schedule pickups without the latest inventory data. Errors multiply when your team can't trust what system has the truth. And when spot market volatility is the norm, static data just isn’t good enough.

Industry Reality: The Speed of Freight Is Outrunning Spreadsheets

The freight market is moving faster than manual processes can handle. According to Gartner, by 2026 more than 50% of supply chain decisions will rely on real-time data augmented by AI and machine learning. That’s not fluff — it’s a reflection of how increasingly difficult it is to operate without live data.

In 2023 alone, over 40% of 3PLs reported losses or fines related to missed SLAs due to information lags. Even basic visibility like “Where is the truck right now?” is complicated by lack of integrations, disjointed communication between systems, and human-entered errors.

And it isn’t just about visibility. It’s about turning that visibility into action — rerouting freight, rebooking a carrier, or applying a fuel surcharge update — before the delay hits the customer.

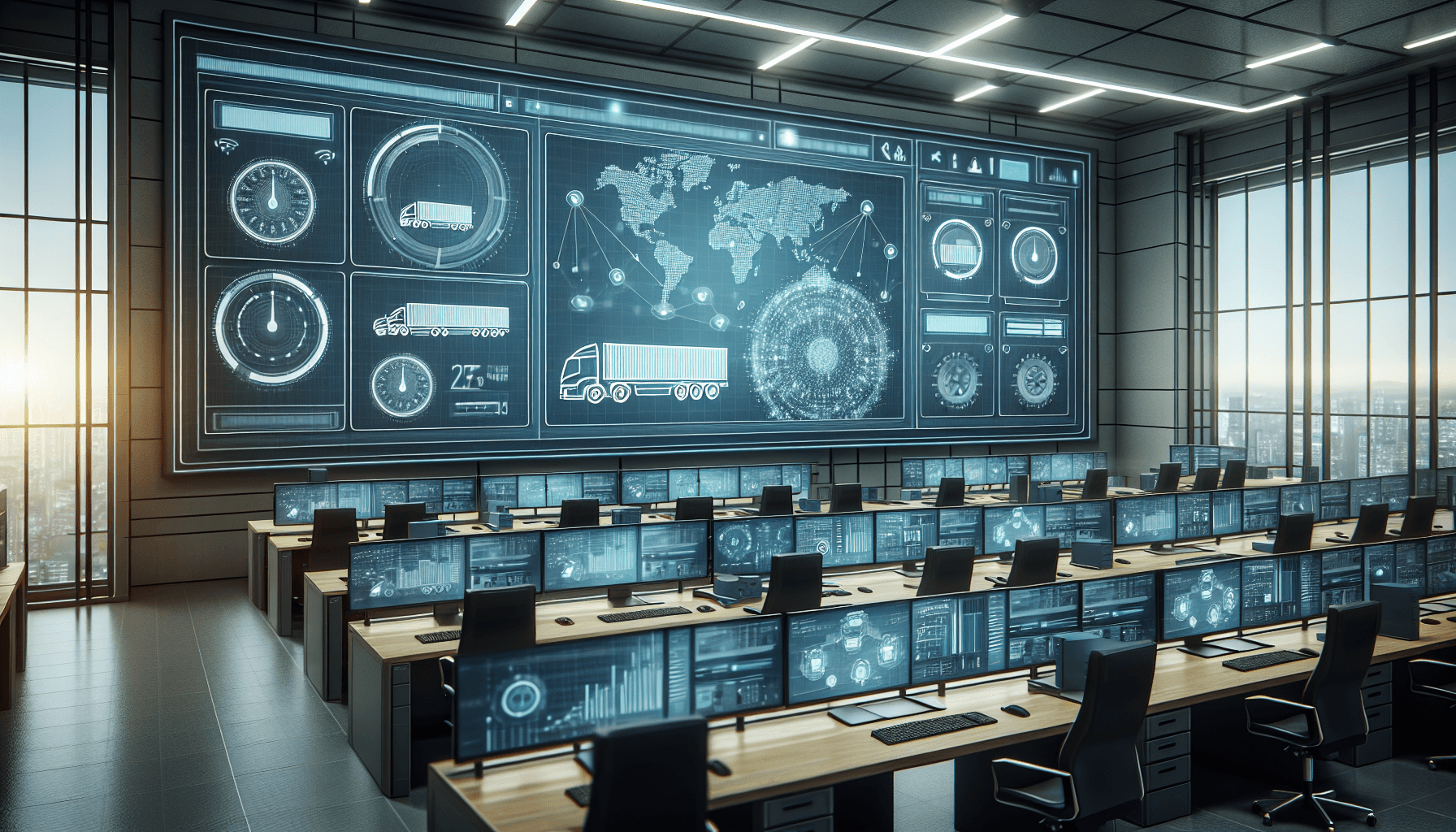

Solution Approach: Real-Time Data That Actually Moves With Your Freight

Fixing freight data bottlenecks starts with making systems talk to each other — and not just dumping raw data. Smart 3PLs are solving this with a three-part approach:

- Centralized data layer that aggregates from TMS, truck GPS, carrier APIs, WMS, and customer systems

- Automation of repetitive tasks, like extracting BOL line items, validating addresses, and flagging rate discrepancies

- Proactive exception workflows that surface data issues before they become delivery or billing failures

For example, one 3PL managing 2,000 daily FTL loads used APIs to pull status updates directly from ELD devices and made this the single source across TMS and customer tools. Result? A 28% reduction in manual check calls and a 6-hour per day productivity gain across dispatchers.

How Debales.ai Helps

Debales.ai plugs into your logistics stack and automates the tough, high-friction parts of your 3PL workflow. It syncs across systems to streamline handoffs and surface accurate, real-time freight data — whether you're matching carrier capacity, resolving exceptions, or handling BOL discrepancies.

Say goodbye to toggling between five tabs or chasing paper trails. Debales.ai uses AI to extract data from load documents, normalize formats across systems, and provide a live dashboard tailored to freight ops. That means fewer errors, faster bookings, and more proactive freight management.

Actionable Takeaways for Operations and Freight Teams

Here’s what logistics managers and 3PL leaders can do right now to fight data slowdowns:

- Audit your current data sources: List what systems provide order, shipment, asset, and carrier data. Are they connected?

- Map exception workflows: Where does someone need to re-enter or manually clean up data, like from BOLs or rate confirmations?

- Prioritize system integrations: Connect your TMS to ELDs, ERPs, and customer systems, so nothing gets lost in email

- Use AI to extract from unstructured docs: Whether it’s invoices, load tenders, or rate sheets, stop with manual entry

- Build alerts around data gaps: Set up triggers for missing pickup events, stale statuses, or delivery mismatches

Closing: It Doesn’t Have to Be This Hard

Data chaos doesn't have to be the default in freight ops. The tools exist, and the ROI is real. When you combine real-time visibility with smart automation, you get smoother workflows, happier customers, and fewer missed margins.

You're not just moving freight — you're moving decisions. The faster and cleaner your data flow, the faster your business can scale.

Ready to unclog your freight data? Debales.ai can help.