Why Data Lag Is Killing Freight Efficiency

Friday, 13 Feb 2026

|

Is Your Freight Operation Running on a 2-Day Delay?

If your TMS data is 48 hours behind what’s actually happening on the dock, you're not alone. In a recent industry survey, 63% of logistics managers reported relying on batch updates instead of real-time data flows. That means critical routing errors, detention fees, and service failures are being discovered after they’ve already cost you money.

The Problem: Delayed Data Is Delayed Decisions

For freight brokers, 3PL operators, and supply chain leaders, the damage from data lag compounds fast. Between manual BOL entry, disjointed systems, and warehouse handoffs, visibility gaps form during the most critical points of the shipment lifecycle.

Consider this: dispatch schedules change, but your routing doesn’t update. A carrier misses pickup, but the client isn't notified. Inventory arrives at cross-dock unannounced, overwhelming dock staff. All of this stems from a simple but destructive problem - outdated, siloed information.

And when decisions rely on outdated information, every KPI suffers: OTIF rates dip, accessorial costs spike, and customer confidence erodes.

The Industry Context: Lag Isn’t Just Common - It’s Credible Risk

It’s not just an operational nuisance, it's a measurable liability. According to FreightWaves research, shippers lose an average of 5-8% in efficiency due to delays related to data retrieval and entry. Another McKinsey report found nearly 70% of supply chain digitization efforts still rely on manual inputs across WMS, TMS, and ERP platforms.

Add in the fragmented nature of 3PL networks - think upstream warehouse partners, mid-mile carriers, LTL handoffs, cold chain providers - and you’ve got a perfect storm of systems that don’t talk to each other fast enough.

When load data, driver ETAs, and inventory counts aren’t continuously synced, you’re left fire-fighting downstream issues that should’ve been corrected upstream.

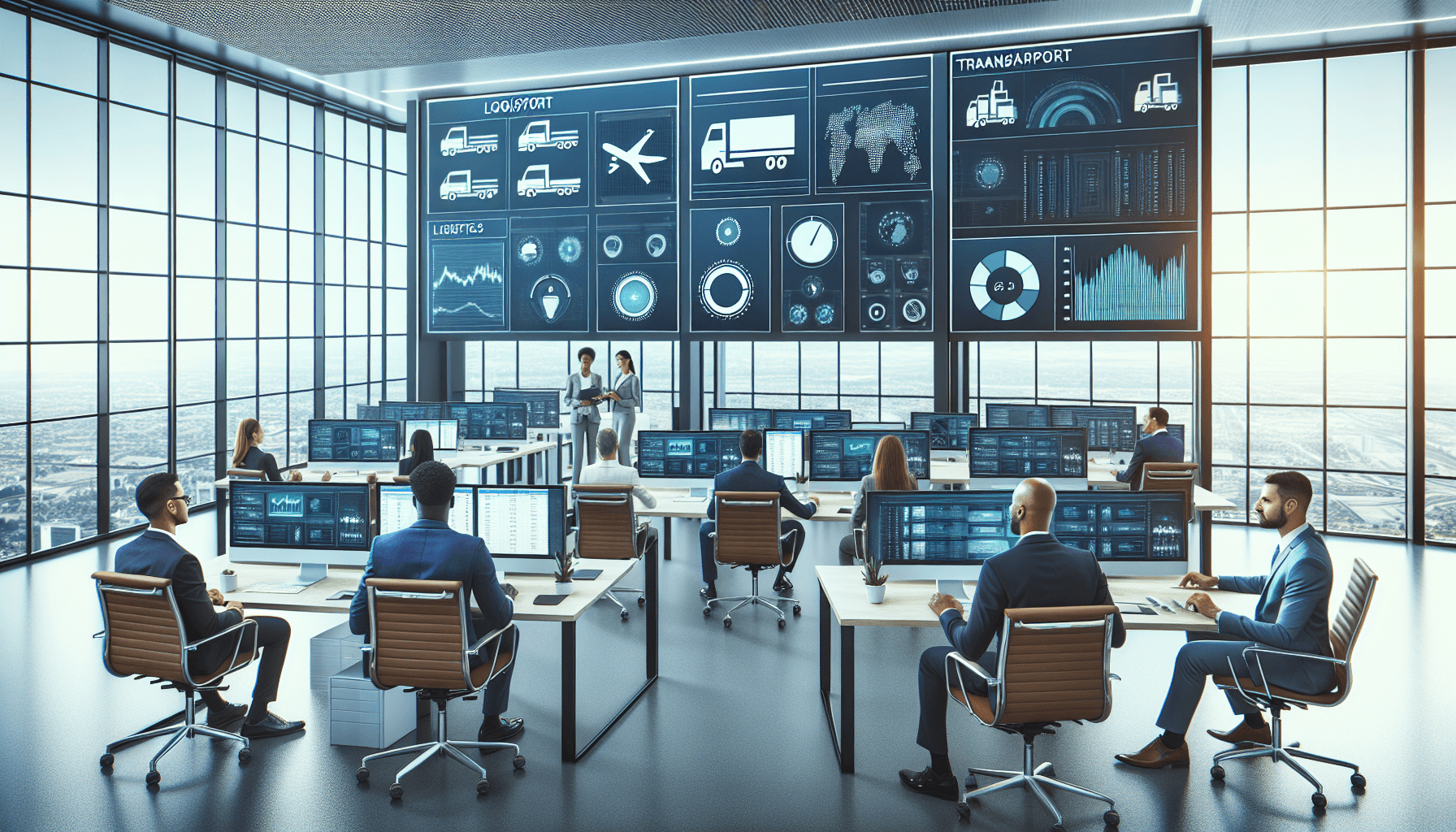

The Solution: Real-Time Orchestration Across the Freight Network

Eliminating lag starts with linking the people, platforms, and processes across your logistics operation. That means:

- Syncing real-time updates across your TMS, WMS, and ERP

- Automating data extraction from shipment documents like PODs, invoices, and BOLs

- Creating shared visibility layers between warehouse teams, carriers, and brokers

- Reducing manual entry and error-prone handoffs

It isn't about replacing your current stack. It’s about filling the gaps that prevent your existing tools from performing at their best.

How Debales.ai Helps

Debales.ai uses AI-powered data streams to eliminate lag across freight workflows. Our platform automatically ingests and syncs shipment details from BOLs, invoices, dock schedules, and even driver messages - regardless of system.

So instead of waiting hours (or days) for updates to populate across disconnected platforms, your team is working with live, complete data. That helps 3PLs reroute faster, brokers update load boards more accurately, and supply chain leaders avoid costly blind spots.

Takeaways for Freight Ops Leaders

If you're running freight ops, here’s how to get ahead of the lag:

- Audit your data latency: Where are updates lagging - carrier ETAs? Warehouse receipts? Invoicing?

- Map your data handoffs: Identify where information is transferred manually, or where it stops flowing entirely.

- Prioritize cross-system visibility: Focus on syncing systems over replacing them.

- Deploy automation tactically: Use AI for extracting and syncing shipment and document data at scale.

- Trust but verify: Pair automation with alerts or exception flows so bad data doesn’t get automatically passed downstream.

Final Thought: Lag Is Optional Now

Every hour counts in freight. And lag isn’t just costing time - it’s bleeding margin. The tech is here to give your team real-time visibility without a full system overhaul. The question is, can you really afford to keep making decisions days after they matter most?