Why Freight ETA Accuracy Still Fails (And How to Fix It)

Tuesday, 3 Feb 2026

|

Missed Another Delivery Window? You're Not Alone

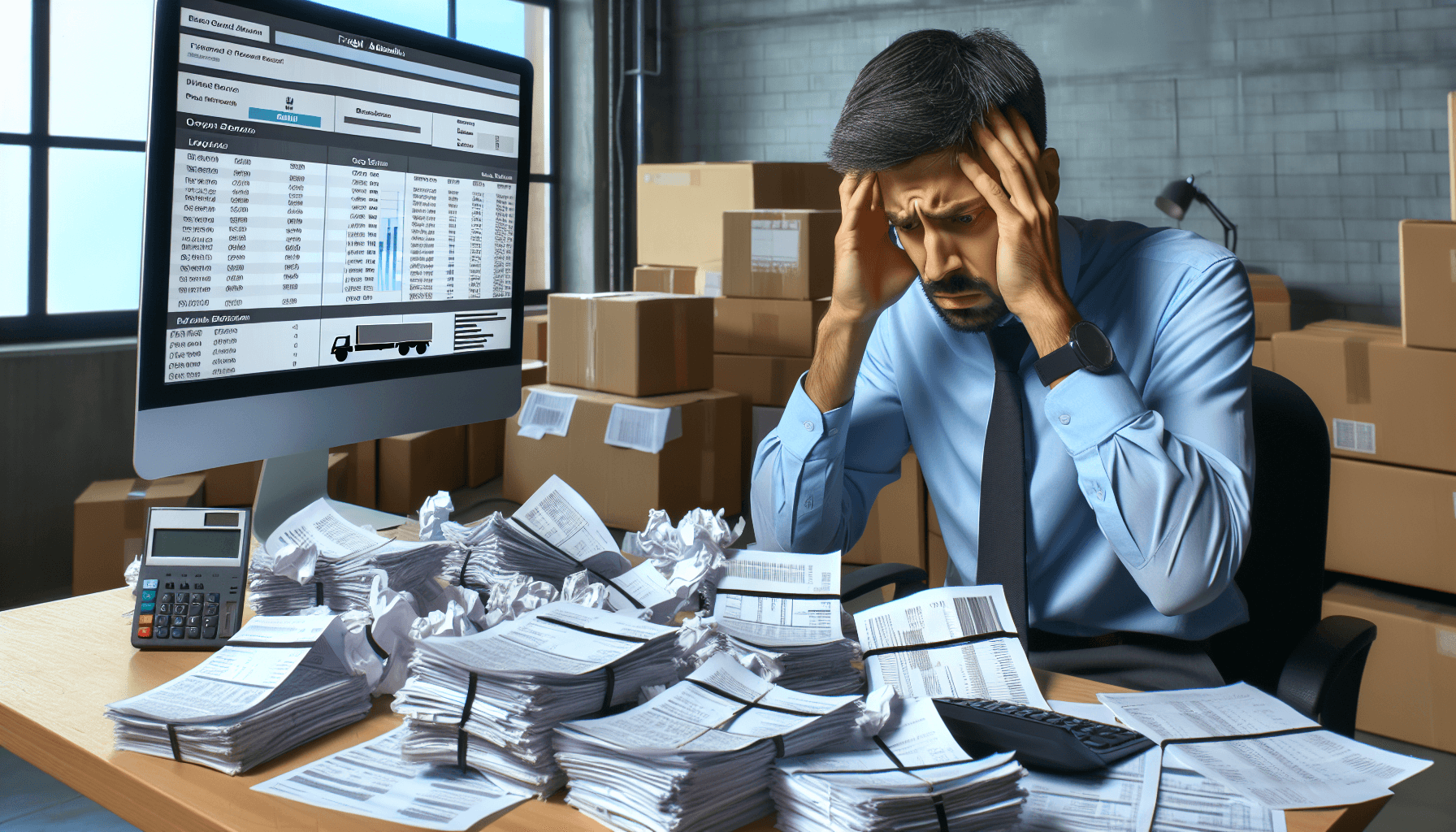

82% of logistics managers report failed or delayed deliveries due to inaccurate ETAs. That stat comes from a 2023 Northridge Group study, and it highlights what ops teams already feel: for all the tech out there, predicting freight arrival times still feels like guesswork.

Late arrivals don't just cause inconvenience—they trigger downstream chaos. Customer SLAs get breached. Docks get overbooked. Planners scramble, and detention fees rack up. Everyone loses.

---

What's Broken About Freight ETAs

Let's not pretend ETA accuracy is a new problem. But what makes it persist in 2026?

The crux: the data sources used for ETA calculations are fragmented, inconsistent, and often stale. Carriers use different systems. Visibility platforms rely on pings that go dark in rural corridors. Manual updates are slow or just plain wrong. And weather? Traffic? Real-time routing decisions? Usually not factored in.

Worse, global shippers operating across regions often cobble together patchwork tracking systems. The result? Conflicting data and a lot of internal guesswork.

---

The Context: Expectations Are Rising, But So Are Data Gaps

In the past five years, customer expectations around freight visibility have skyrocketed. 93% of shippers now demand real-time tracking and precise ETAs from their logistics partners, according to FreightWaves Research.

Yet the tools in use haven’t kept up. A 2024 Accenture report found that only 37% of global supply chain leaders can confidently say their ETA data is accurate within a two-hour window. Two hours! In a world where Amazon delivers within one.

And it’s not just about customer frustration. Inaccurate ETAs cost shippers and carriers an average of 6-10% in avoidable expenses–think missed dock appointments, idle labor, and penalties.

---

A Better Approach: Multi-Layered, Adaptive ETA Modeling

To address ETA failures, shippers need smarter signal processing. That means:

- Multi-source data ingestion: Blending ELD, telematics, TMS, weather, and traffic.

- Real-time updates: Continuous recalculation based on latest conditions and GPS events.

- Predictive models: Using AI to recognize route patterns, carrier behavior, and even driver tendencies.

- Confidence scoring: Assigning accuracy thresholds to each ETA, so teams know when to trust the number.

We’re not talking theoretical improvements—these methods have proven to reduce late delivery rates by over 25% in controlled pilots. And with machine learning in the mix, ETA confidence actually improves over time.

---

How Debales.ai Improves ETA Precision

Debales.ai isn’t just another visibility dashboard. Our platform uses adaptive modeling that continuously ingests over 50 data signals per freight unit—from weather and port congestion to historical carrier behavior.

Instead of showing you an ETA, we show you how likely it is to hold, flag outliers early so your team can step in before the delay happens, and help you auto-prioritize which problems need attention based on freight value, SLA risk, and customer impact.

Teams using Debales.ai have seen up to a 32% drop in detention costs and a 48% reduction in missed dock appointments—all from improvements in ETA accuracy and alerting.

---

What You Can Do Today

Want to start fixing ETA issues this quarter? Focus on these steps:

- Audit your current data sources. Where does your ETA come from—GPS pings? Carrier APIs? Manual updates? Know your blind spots.

- Start tracking ETA variance. Benchmark how often your predicted and actual arrival times align. You can't fix what you don't measure.

- Push for integrations. Even modest new data inputs (like weather overlays or TMS sync) can improve accuracy significantly.

- Train teams on confidence scoring. A single ETA isn't helpful if no one knows how trustworthy it is. Use thresholds.

- Create SOPs for ETA exceptions. When the platform flags a risk, what happens next? Having playbooks reduces reaction time.

---

Freight Doesn’t Have to Fly Blind

The logistics world has sensors on everything—from pallets to ports—but insight is still getting lost in transit. Fixing ETA accuracy isn’t just about better tech. It’s about breaking out of static data and adapting to real-world conditions in real time.

Shippers that close the visibility gap aren’t just more efficient. They’re more trusted. In a supply chain landscape where dependability is a differentiator, accurate, explainable ETAs are a competitive edge.

Let’s stop guessing. The data’s already out there. You just need a way to harness it.