How AI Automates and Improves Inventory Management in Logistics?

Sunday, 28 Sep 2025

|

In What Ways Does AI Automate and Improve Inventory Management?

The cost of inventory mismanagement is staggering: stockouts lose $1 trillion in sales globally each year, while excess inventory ties up an estimated $1.5 trillion in working capital. For logistics operations, the challenge isn't just knowing what's in stock—it's predicting what should be in stock, when, where, and in what quantities.

Traditional inventory management relies on manual counts, periodic audits, and rule-based reorder points that struggle to keep pace with volatile demand patterns. AI-powered inventory management transforms this reactive approach into a proactive, predictive system that reduces costs by 20-35%, improves accuracy to 99%, and automates processes that once consumed countless labor hours.

For decision-makers seeking competitive advantage through operational excellence, understanding how AI revolutionizes inventory management isn't optional—it's essential for survival in increasingly complex supply chains.

Wondering what separates AI-powered inventory systems from basic warehouse management software? The answer lies in prediction, automation, and continuous optimization at a scale impossible for human teams.

The Fundamental Problems with Traditional Inventory Management

Manual and semi-automated inventory systems face persistent challenges:

Reactive Decision-Making: Reorder points based on static rules don't adapt to changing demand patterns, seasonality shifts, or market disruptions

Labor-Intensive Processes: Manual cycle counts, physical audits, and spreadsheet-based tracking consume valuable time while remaining error-prone

Limited Visibility: Fragmented data across locations makes it difficult to see true inventory positions or optimize stock placement

Inaccurate Forecasting: Simple statistical methods fail to capture complex relationships between demand drivers

Slow Response Times: Weekly or monthly planning cycles can't keep pace with daily market fluctuations

The result? Simultaneous stockouts and overstock situations, eroded margins, disappointed customers, and wasted labor.

For context on how AI differs from traditional automation, explore What's the Difference Between AI, Machine Learning, and Automation in a Warehouse Context?.

How AI Automates Inventory Management

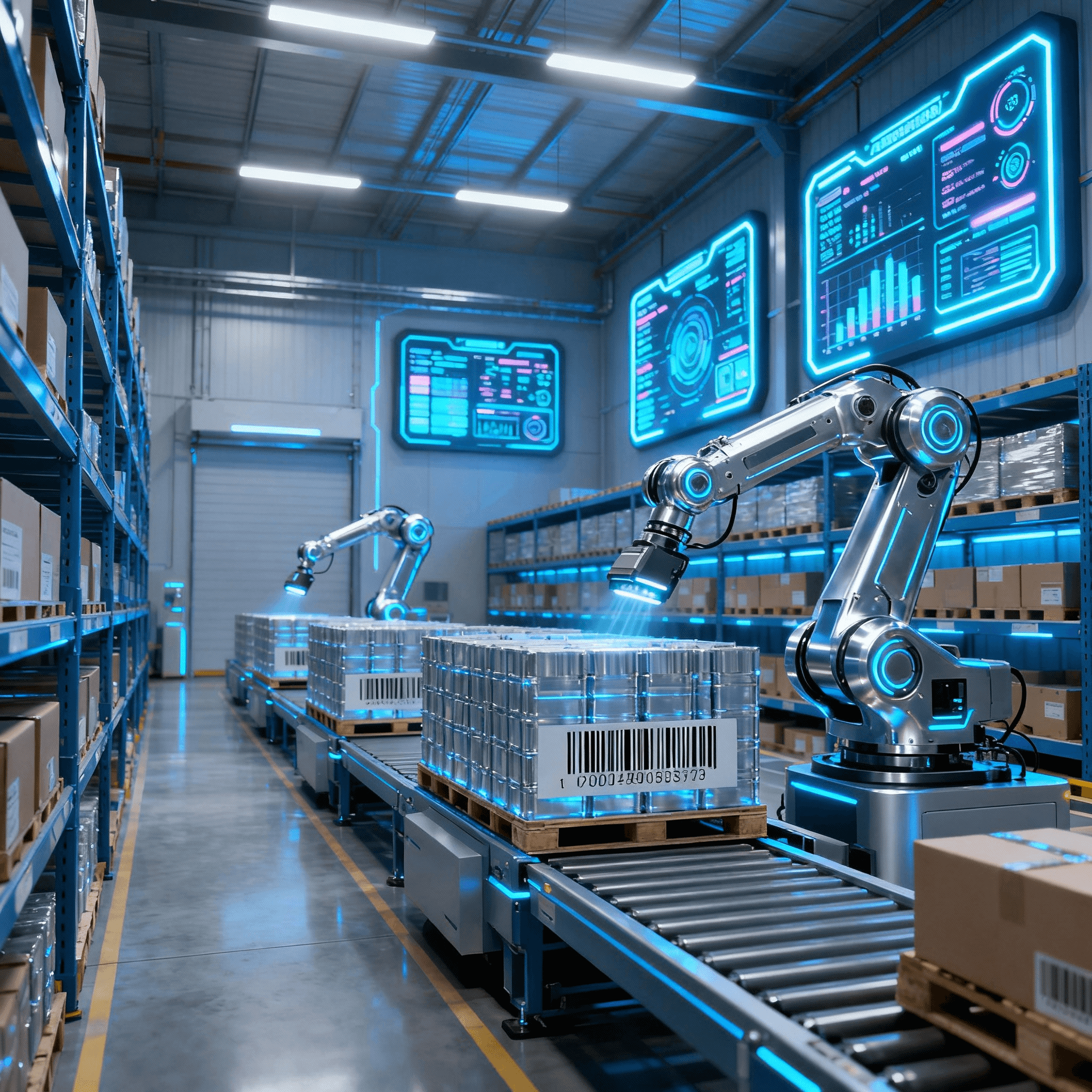

1. Automated Real-Time Tracking and Monitoring

AI-powered systems integrate with IoT sensors, RFID readers, barcode scanners, and warehouse management systems to automatically track inventory movements without manual intervention.

Automation capabilities:

- Continuous monitoring of stock levels across all locations in real-time

- Automatic updates as products move through receiving, storage, picking, and shipping

- Instant flagging of discrepancies, misplaced items, or potential shrinkage

- Elimination of manual cycle counting and data entry

Business impact: Walmart implemented IoT sensors with AI-powered tracking, automatically triggering restocking orders when levels fall below thresholds, reducing inventory costs while improving availability.

This visual tracking capability connects to technologies detailed in How Computer Vision Technology Helps in Logistics Operations.

2. Intelligent Automated Reordering

Rather than relying on fixed reorder points, AI systems dynamically calculate optimal reorder timing and quantities based on predictive demand forecasts, supplier lead times, and carrying costs.

How it works:

- AI analyzes historical consumption patterns, seasonality, and external factors

- Algorithms calculate economic order quantities (EOQ) optimized for current conditions

- Systems automatically generate purchase orders when predictive models indicate needs

- Adjustments occur continuously as demand signals change

Result: Businesses report 30-50% reduction in manual purchasing workload while maintaining 95%+ service levels.

3. Automated Multi-Location Inventory Balancing

For operations with multiple warehouses or distribution centers, AI automatically optimizes stock placement and inter-facility transfers.

Optimization includes:

- Analyzing regional demand patterns to pre-position inventory closer to anticipated needs

- Automatically recommending or executing inventory transfers between locations

- Balancing stock levels to minimize total system inventory while maximizing service

- Coordinating with transportation systems for cost-effective redistribution

Amazon's AI system automatically routes inventory through its fulfillment network, placing products near expected demand centers before orders are even placed.

How AI Improves Inventory Accuracy and Efficiency

1. Predictive Demand Forecasting

AI's most transformative impact comes from dramatically superior demand forecasting accuracy—the foundation of all inventory decisions.

AI forecasting advantages:

- Analyzes hundreds of variables simultaneously (historical sales, promotions, weather, economic indicators, social media trends, competitor activity)

- Detects non-linear patterns and complex relationships traditional methods miss

- Generates SKU-level forecasts tailored to each product's unique characteristics

- Updates predictions continuously as new data arrives

Performance improvement: AI forecasting reduces forecast error by 20-50% compared to traditional statistical methods, directly translating to optimized inventory levels.

For deeper insights into forecasting improvements, read How AI Improves the Accuracy of Demand Forecasting.

2. 99%+ Inventory Accuracy

Manual inventory tracking achieves 60-80% accuracy at best. AI-powered systems routinely achieve 95-99% accuracy through automated data collection and anomaly detection.

Accuracy improvements from:

- Eliminating manual data entry errors

- Continuous real-time tracking vs. periodic physical counts

- AI algorithms detecting and flagging discrepancies instantly

- Machine learning identifying patterns of shrinkage or misplacement

Gartner research: AI in warehouse management improves inventory accuracy to 95%+, reducing inventory costs by up to 20%.

3. Optimized Safety Stock and Reorder Points

Rather than rule-of-thumb safety stock calculations, AI dynamically optimizes buffer inventory levels based on demand variability, supplier reliability, and service level targets.

Dynamic optimization:

- Adjusts safety stock by SKU based on actual demand volatility

- Factors in supplier lead time variability and reliability histories

- Balances carrying costs against stockout risks mathematically

- Adapts to changing conditions without manual recalculation

Result: 20-30% reduction in safety stock requirements while maintaining or improving service levels.

4. Intelligent ABC Analysis and SKU Segmentation

AI automatically segments inventory into categories requiring different management approaches, continuously updating classifications as patterns change.

Smart segmentation:

- Identifies fast-movers, slow-movers, and dead stock automatically

- Recommends differentiated reorder strategies by product category

- Flags products approaching obsolescence for clearance or discontinuation

- Optimizes warehouse placement—high-velocity items in prime pick locations

Real-World Impact: Measurable Business Outcomes

Organizations implementing AI-powered inventory management report consistent, significant improvements:

Cost Reduction

- 20-35% decrease in total inventory carrying costs

- 15-25% reduction in working capital tied up in stock

- 30-50% labor savings from automated processes

- Reduced emergency expediting costs through better planning

Performance Improvement

- 95-99% inventory accuracy vs. 60-80% manually

- 20-30% reduction in stockouts improving customer satisfaction

- 25-40% decrease in excess and obsolete inventory

- Improved inventory turnover ratios by 15-30%

Operational Efficiency

- 70-80% reduction in time spent on manual inventory tasks

- Real-time visibility across all locations and channels

- Faster response to demand changes (hours vs. weeks)

- Better vendor negotiations through data-driven insights

Example: Walmart's AI-powered inventory system analyzes data from e-commerce, social media, and sales trends to improve forecast accuracy and reduce stockouts, yielding significant inventory cost reductions while improving customer satisfaction.

To understand how these improvements integrate with broader supply chain intelligence, visit What is an AI-Powered Control Tower in Logistics?.

AI Inventory Management Technologies in Action

Machine Learning Algorithms

The computational engine behind AI inventory systems includes:

- Regression models: Predicting demand based on historical patterns and external variables

- Neural networks: Capturing complex non-linear relationships in demand drivers

- Ensemble methods: Combining multiple models for superior accuracy

- Reinforcement learning: Optimizing reorder policies through trial and learning

Explore these algorithms in depth at Most Common AI Algorithms Used for Route Planning and Demand Forecasting.

IoT and Sensor Integration

Physical tracking technologies feeding AI systems:

- RFID tags: Automatic identification without line-of-sight scanning

- IoT sensors: Monitoring inventory levels, temperature, humidity, and location

- Computer vision: Visual inventory counting and verification

- Smart shelves: Weight sensors detecting stock depletion in real-time

Predictive Analytics Platforms

Advanced software combining data integration, machine learning, and business logic to generate actionable recommendations automatically.

How debales.ai Delivers AI-Powered Inventory Intelligence

At debales.ai, our AI platform integrates advanced inventory management capabilities designed specifically for logistics operations:

Predictive Demand Forecasting: Multi-model ensemble approach automatically selecting optimal algorithms per SKU for superior accuracy

Automated Replenishment: Intelligent reorder recommendations considering demand forecasts, lead times, and cost optimization

Real-Time Visibility: Unified dashboard integrating data from WMS, ERP, and IoT devices for complete inventory transparency

Multi-Location Optimization: AI-driven recommendations for stock balancing and inter-facility transfers

Explainable AI: Transparent reasoning showing why recommendations are made and what factors drive predictions

Seamless Integration: Connects with existing inventory systems without complex custom development

Our approach combines the predictive power detailed in How Predictive Analytics Works for Logistics with automated decision support.

Implementation Best Practices

Successful AI inventory implementations follow structured approaches:

1. Start with Data Quality: Ensure inventory data is clean, normalized, and integrated across systems

2. Begin with High-Impact SKUs: Focus initial AI deployment on products where improvements deliver maximum value

3. Establish Clear Metrics: Track forecast accuracy, inventory turns, service levels, and costs to demonstrate ROI

4. Maintain Human Oversight: AI should augment human judgment, especially for strategic decisions and exceptions

5. Continuously Refine: Regularly evaluate model performance and retrain with new data as conditions evolve

For insights into data requirements, read What Kind of Data is Needed to Train an Effective AI Model for Supply Chain Optimization?.

The Future: Autonomous Inventory Management

Next-generation AI systems are evolving toward fully autonomous inventory management—where AI not only recommends but automatically executes purchasing, allocation, and transfer decisions within defined parameters.

This autonomous capability represents the vision described in A Simple Analogy for How AI Optimizes a Supply Chain—intelligent systems that learn, adapt, and optimize continuously.

Moving from Manual to Intelligent

The question facing logistics leaders isn't whether to adopt AI-powered inventory management—it's how quickly they can implement it before competitors gain insurmountable advantages through 20-35% cost reductions and 95%+ accuracy rates.

Organizations still relying on manual processes and basic WMS systems face widening efficiency gaps against AI-enabled peers achieving dramatically superior performance.

Ready to transform inventory management from operational burden into competitive advantage?

Discover how debales.ai's AI-powered platform delivers industry-leading inventory accuracy, automated replenishment, and predictive optimization—reducing costs while improving service levels.

Book a demo with debales.ai today and experience the difference AI makes for inventory efficiency, working capital optimization, and bottom-line performance.

All blog posts

View All →

Tuesday, 3 Mar 2026

Why accessorials keep wrecking your freight margins

Detention, TONU, reweighs, and lumper fees keep killing margin. Here is why it happens and how to control accessorials this week.

Tuesday, 3 Mar 2026

Why our freight data keeps lying (and what to do)

Late ETAs, surprise accessorials, and messy invoices start with bad freight data. Here’s how ops teams can fix it without new headcount.

Tuesday, 3 Mar 2026

Why accessorials keep blowing up your freight budget

Detention, lumper, reclass, and redelivery fees keep creeping in. Learn why accessorials happen and how to cut disputes and overcharges fast.