Why Your Logistics Data Is Costing You Millions

Friday, 6 Feb 2026

|

Are You Flying Blind with Your Logistics Data?

73% of shippers say lack of real-time visibility is their biggest logistics challenge. Let that sink in. In an industry that thrives on precision and predictability, it’s shocking how often teams try to manage chaos with spreadsheets and delayed updates.

If you’ve ever scrambled to locate a shipment, reconcile conflicting BOLs, or get a status update from a carrier during a customer call—you're not alone.

The Problem: Disconnected, Delayed, and Dirty Data

Let’s face it: most logistics and freight data lives in silos. Your WMS doesn’t talk to your TMS. Your 3PL portal updates hours after trucks have moved. And your ERP may still rely on batch files or manual inputs from operations teams.

That disconnect leads to real-world fallout:

- Missed delivery windows because route updates didn’t reach dispatch

- Extra detention charges due to inaccurate appointment data

- Hours wasted consolidating reports across systems just to answer basic questions like "What's the on-time rate this week?"

When your data isn’t timely, connected, or trusted, you're not managing a supply chain. You're reacting to it.

Industry Context: Visibility Gap Is Industry-Wide

The visibility problem isn't new—and it's massive. According to Inbound Logistics, 94% of supply chain professionals say visibility gaps impact customer satisfaction. Meanwhile, McKinsey reports companies that invest in supply chain visibility tech see service levels improve by 20-30% and inventory costs drop by up to 25%.

Third-party logistics (3PL) providers and freight brokers face unique pain points. With so many integrations (carrier APIs, EDI feeds, warehouse systems), standardizing and centralizing data is a constant uphill climb. LTL and FTL data flows differently. Drayage and cross-dock operations bring a whole other layer of complexity.

And when you factor in exceptions—damaged freight, last-minute reconsigns, customs delays—that complexity becomes chaotic fast.

The Solution: Real-Time, Connected Decision Intelligence

The answer isn't just "more data." It’s better data—real-time, verified, and accessible in one place.

What does that look like in practice?

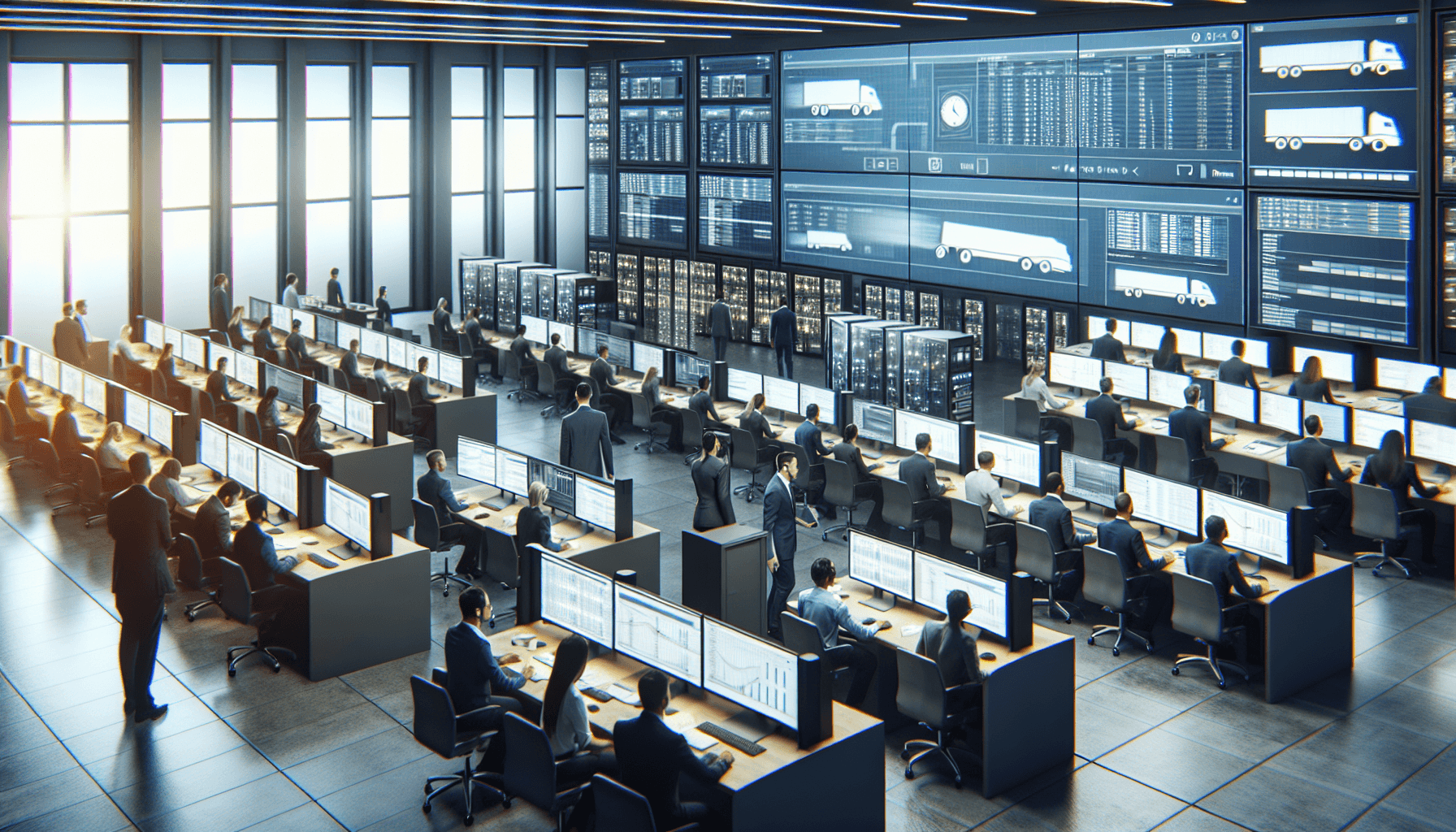

- Unified dashboards where teams see shipment status, exceptions, and performance metrics across carriers, modes, and partners

- Automated workflows that alert the right person when a shipment goes off schedule

- Data harmonization so your BOL, POD, and invoice data actually matches

It sounds simple, but few teams are truly operating at this level—even big ones. The cost of waiting? Lost margin, strained customer relationships, and frustrated ops teams stuck in email threads.

How Debales.ai Helps

Debales.ai brings clarity to your freight and logistics data. Our platform normalizes and connects live feeds from carriers, warehouses, and systems like TMS, WMS, and ERP. Instead of toggling between portals or chasing emails, your team sees what’s happening now—and what needs attention—on one screen.

Logistics leaders use our machine learning to predict delays before they snowball and automate exception handling across shipment types (LTL, FTL, drayage, etc.). No more flying blind. Just smart, connected decisions.

Actionable Tips for Logistics and Ops Leaders

Here’s how to start improving your data visibility now:

1. Audit your data sources List all your inbound data streams. Identify what's real-time, what's delayed, and where duplication or conflicts occur.

2. Eliminate manual touchpoints Use EDI/API integrations where possible. Reduce rekeying BOL or shipment data between systems—it’s a prime source of error.

3. Define your critical metrics On-time delivery rate, dwell time, carrier compliance—make sure these are measured in the same way across systems. Standardization unlocks insights.

4. Prioritize exception management Not all updates are equal. Set alerts for shipment issues that impact cost and customer experience: delays, accessorials, rejections.

5. Align your ops and IT teams Better data flow requires cross-functional buy-in. Build a shared roadmap that connects platforms and defines what “truth” looks like.

Final Thought: Visibility Isn't a Luxury

Every hour a shipment goes untracked, a customer gets nervous. Every mistake in a POD or an invoice eats margin. Visibility isn't just nice to have—it’s infrastructure.

The good news? You don’t need to rebuild from scratch. Start by surfacing the gaps, prioritize where data can drive better outcomes, and upgrade your decision-making from reactive to real-time.

When your data works for you, so does your supply chain.