Predictive Maintenance AI for Fleet Downtime Reduction and Cost Control

Wednesday, 28 Jan 2026

|

Most fleets are not “bad at maintenance.” They are overloaded. The uncomfortable truth is that downtime is often created in the gaps between good intentions: the missed follow-up, the late inspection, the “run it one more day,” the parts that were not staged, the unit that came back with a complaint that never made it into a work order. It looks like work, not failure. Your team is busy, competent, and trying to keep trucks moving. That is exactly why the leakage persists.

Why good teams normalize downtime and repeat repairs

In transportation operations, the system rewards urgency. Freight still needs to move, drivers still need equipment, and customers still expect service consistency. Over time, even disciplined teams normalize inefficiencies because the alternative is service disruption.

Three patterns show up repeatedly:

1) Heroics over process. The best tech, the most experienced dispatcher, or the “go-to” shop coordinator keeps saving the day. That hero work is real value, but it masks the underlying signal: decisions are being made without stable evidence and repeatable follow-through.

2) Tribal memory over shared context. Someone “just knows” that Unit 214 always eats batteries in winter, or that a specific trailer has a brake issue that comes back every few months. That knowledge is useful, but it does not scale across shifts, locations, or turnover.

3) Calendar and compliance over condition. PM intervals and inspections are necessary, but they are blunt. The fleet changes by route mix, driver behavior, load profiles, idle time, and weather. The schedule rarely reflects the true risk of failure.

When you add telematics, ELD notes, DVIRs, shop notes, and invoices, you have plenty of data. What you often do not have is a consistent way to turn that data into maintenance decisions that prevent the next failure instead of documenting the last one.

Symptom checklist you can observe this week

If predictive maintenance ai is relevant for your operation, you will see some version of these symptoms. You do not need a long assessment to notice them.

Quick checklist

1) Repeat work orders for the same component within 30 to 90 days, often labeled “could not reproduce” or “monitor.”

2) Road calls that start as “minor” and become multi-day events because parts and bay time were not staged.

3) PMs that are on time, but failure rates do not improve, especially for tires, batteries, brakes, cooling, and aftertreatment related issues.

4) Units that bounce between “fine” and “out of service,” creating dispatch churn and driver frustration.

5) Maintenance scheduling conflicts where high-availability assets get pulled in while high-risk assets stay on the road.

Quiet math: what downtime and repeat repairs quietly cost

This is not about external benchmarks. Use your own rates. The goal is to make the hidden cost adjustable and visible.

Consider a scenario where you run 200 power units.

- Average unplanned downtime: 0.6 days per unit per month (adjust up or down)

- Margin impact per down day: $450 (lost contribution after variable costs, not revenue)

- Road call and recovery average: $650 per event

- Share of downtime tied to preventable failure modes: 35% (conservative if you have recurring issues)

Step through it:

1) Total down days per month: 200 units x 0.6 = 120 down days

2) Monthly margin impact: 120 x $450 = $54,000

3) If 35% is tied to preventable failure modes: $54,000 x 0.35 = $18,900

4) Add road call and recovery: imagine 25 preventable events x $650 = $16,250

In this conservative example, the “preventable slice” is roughly $35,150 per month. Your numbers might be half that or double. The point is that the cost hides across dispatch churn, driver time, shop interruptions, parts expediting, and service misses. The ledger rarely labels it as “downtime reduction opportunity.”

If you want help identifying where this cost hides in your workflows, we run short working sessions to map the top two leak points. The output is a simple view of where evidence is missing and where follow-through breaks between operations, maintenance, and vendors.

What actually changes outcomes: from reactive events to evidence-driven prevention

The lever is not “more alerts.” The lever is consistent, operational decisioning: which assets are most likely to fail soon, what the failure mode probably is, and what action is most likely to prevent it with minimal disruption.

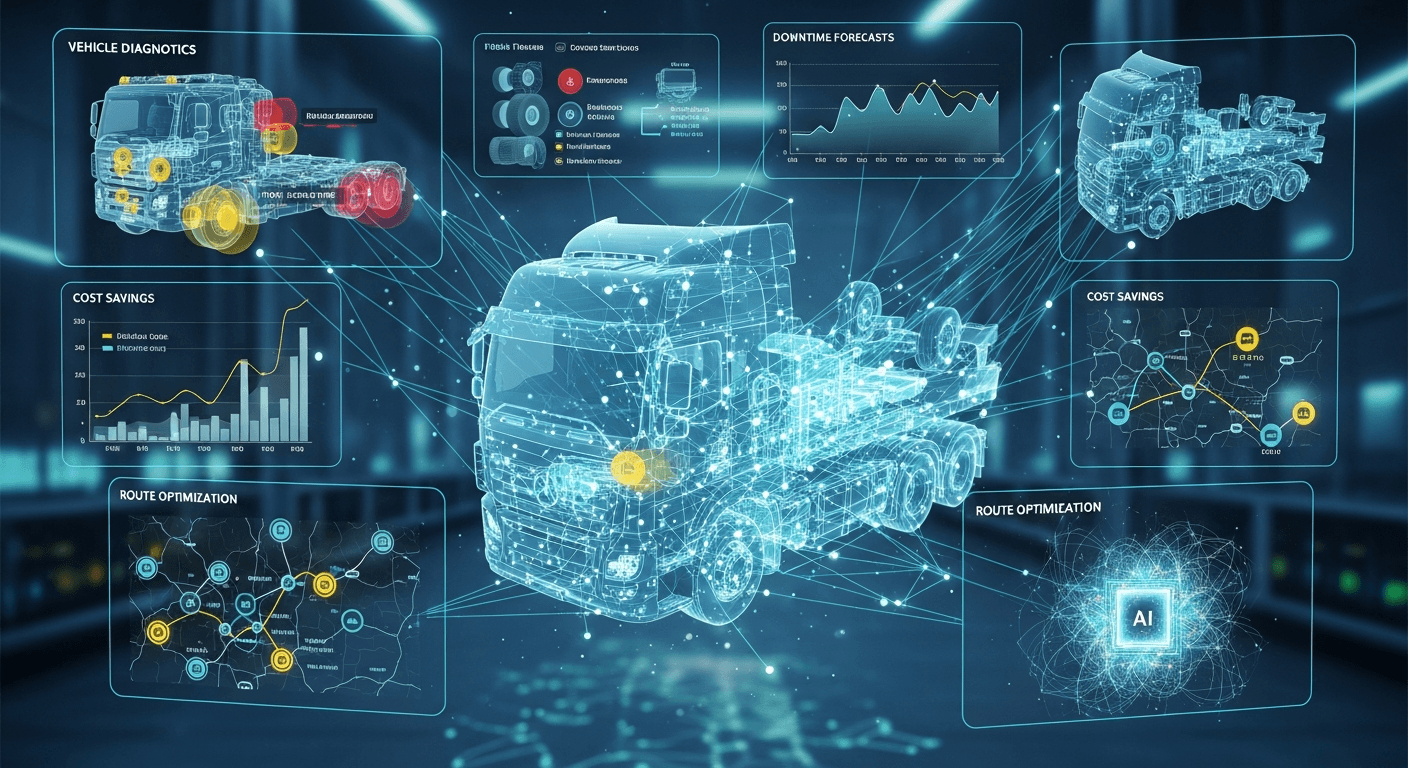

Predictive maintenance ai becomes practical when it ties together three capabilities:

1) Equipment failure prediction grounded in your own patterns

Fleet maintenance analytics should answer a narrow set of questions:

- Which units are trending toward failure in the next 7 to 21 days?

- What component family is implicated (cooling, brakes, tires, batteries, aftertreatment, wheel-end, etc.)?

- What evidence supports the prediction (fault code clusters, temperature deltas, voltage drops, regen frequency, idle behavior, DVIR notes, repeat part replacements)?

This is where telematics data ai and condition monitoring logistics practices matter, but only if they are connected to maintenance outcomes. A prediction that cannot be acted on is just another notification.

2) Maintenance scheduling ai that respects operations reality

The best prediction still fails if the shop cannot absorb it.

Maintenance scheduling ai is less about filling a calendar and more about resolving constraints:

- Bay time and tech skill match (who can do aftertreatment diagnostics vs basic PM)

- Parts availability and kitting

- Driver and load commitments

- Vendor capacity and lead times

- Minimum disruption windows by lane and customer

When scheduling becomes risk-based, you stop pulling in “healthy” units just because the calendar says so, and you stop letting high-risk units run until they break because nobody wants to be the one who takes them out of rotation.

3) Truck maintenance automation for follow-through, not paperwork

Automation that matters is the kind that closes loops:

- Create the right work order with the right context

- Attach evidence and prior history automatically

- Trigger parts staging and vendor requests

- Require a disposition that feeds learning (fixed, adjusted, monitored with threshold, deferred with reason)

This is how you reduce repair costs without asking techs and coordinators to do extra reporting. You are taking repetitive coordination off their plate so they can focus on diagnosis quality.

The work about work that eats your capacity

The hidden constraint is not intelligence. It is time spent on micro-tasks that do not directly fix equipment.

Where time goes in a reactive maintenance loop

- Manually checking multiple systems for fault history, DVIR notes, and last repair

- Calling drivers for clarification because notes are inconsistent

- Re-entering the same issue across telematics, TMS notes, and the maintenance system

- Chasing approvals for borderline repairs because the risk is unclear

- Expediting parts after the unit is already down

- Coordinating tow, vendor, and rental replacements under pressure

- Reopening work orders because the symptom returned and the original context is missing

What to standardize so prevention becomes possible

- A short list of failure modes you agree to target first (start with the top 3 that generate road calls or repeat visits)

- A common definition of “preventable event” and “repeat repair” so analytics are consistent

- A simple evidence package per event: fault clusters, prior replacements, operating conditions, and disposition

- A scheduling rule set: what gets pulled in early, what can wait, and what requires parts on hand before appointment

This is how condition monitoring logistics stops being “data monitoring” and becomes asset reliability shipping discipline: fewer surprises, fewer emergency decisions, steadier service.

A practical 30-minute exercise to find your first two use cases

Do this with one maintenance lead, one dispatcher, and one analyst or coordinator. The goal is not perfection. The goal is alignment.

Step 1 (10 minutes): Pick the failure mode

Choose one category that created visible pain in the last 60 days. Examples: batteries, tires, cooling, aftertreatment.

- Write down how it shows up (symptoms drivers report, common fault codes, typical shop findings).

- List the top three units that had repeat issues.

Step 2 (10 minutes): Map the evidence you already have

For those units, identify what is available today:

- Telematics signals (voltage, temp, pressure, regen activity, fault codes)

- DVIR text and driver comments

- Work order history and parts replaced

- Route attributes (idle heavy, short haul, mountain, stop-and-go)

Then mark what is missing or unreliable (inconsistent notes, wrong timestamps, vendor invoices late, etc.).

Step 3 (10 minutes): Define one preventive action and one scheduling rule

- Preventive action: what would you do if you had 7 to 14 days warning (inspect, test, replace, clean, software update, reroute)?

- Scheduling rule: what must be true before you pull the unit in (parts staged, specific tech available, combine with PM, coordinate with driver home time)?

If you can complete this exercise, you already have the blueprint for a first predictive model and an operational workflow that makes it useful.

But we already have automation…

Most fleets do. You likely have some combination of a maintenance system, telematics platform, alerts, PM schedules, and maybe even dashboards.

The issue is not that tools are missing. The issue is that the system still depends on human interruption at the most fragile moments:

- Someone has to notice the pattern across weeks, not just today’s fault.

- Someone has to decide whether to act now or defer.

- Someone has to coordinate parts, bay time, driver availability, and vendor capacity.

- Someone has to ensure the disposition is captured in a way that improves the next decision.

If your current automation records events and pushes notifications, it can still leave the core decision and follow-through unmanaged. That is where downtime reduction and reduce repair costs initiatives stall, even with good people.

At this point, most teams ask the same question: if this isn't a people problem, and it's not solved by more dashboards or alerts, what actually changes the outcome?

Traditional systems are designed to record and notify; the gap shows up where decisions, evidence, and follow-through still depend on human interruption.

Closing: what to aim for in the next 60 days

A practical target is not “full predictive everything.” It is two failure modes, one region or terminal, and a workflow that connects prediction to scheduling and parts staging.

If you do that, you should expect three operational shifts:

- Fewer surprise downs because you are pulling forward the right work, not more work

- Cleaner shop load because jobs arrive with context and parts, not mystery and urgency

- Better asset availability because high-risk units get handled before they disrupt dispatch

If it makes sense, we can show how teams operationalize the fixes.

https://debales.ai/book-demo?utm_source=blog&utm_medium=content&utm_campaign=predictive-maintenance-ai-for-fleet-downtime-reduction-and-cost-control&utm_content=fleet-downtime-control