What Every Logistics Manager Gets Wrong About ‘Productivity’ (And Why It’s Costing You)

Tuesday, 13 Jan 2026

|

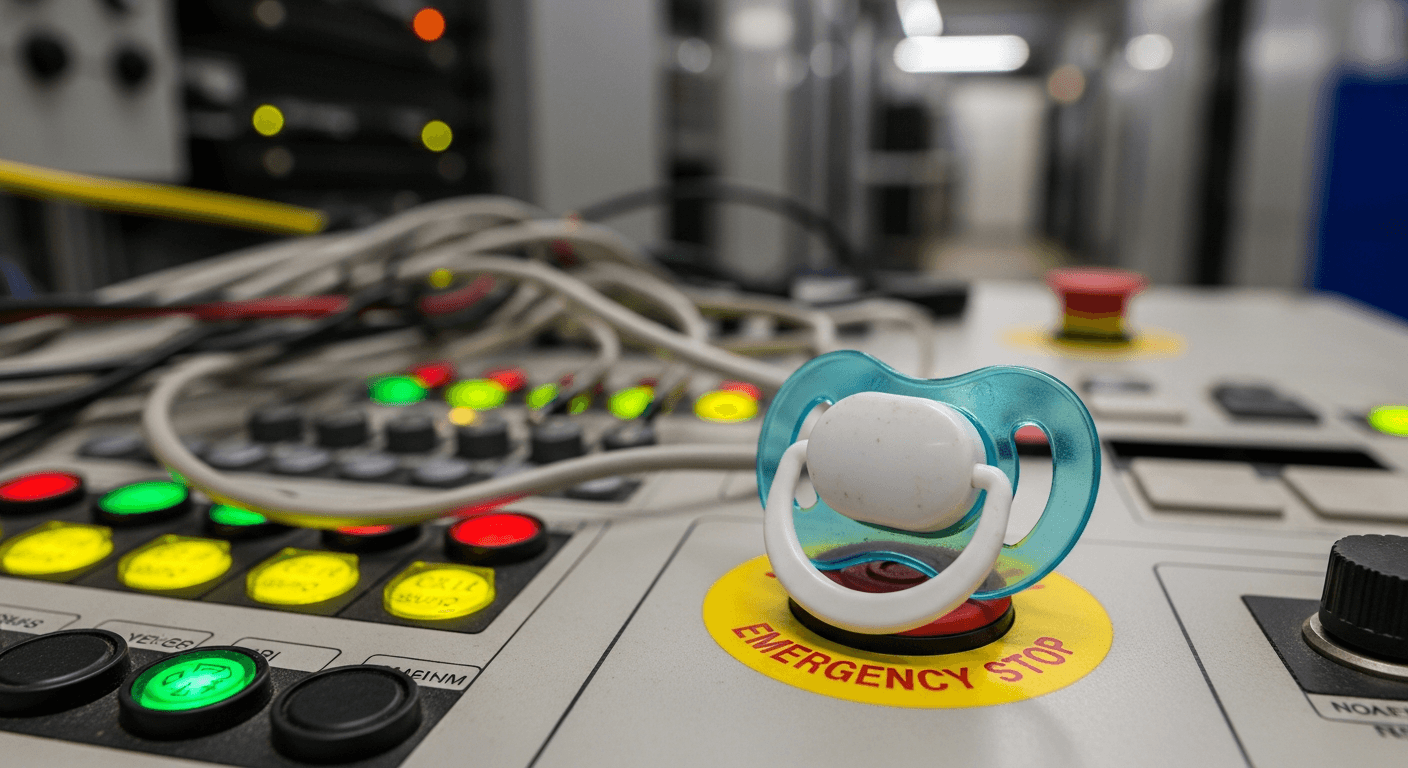

The uncomfortable truth: most “productivity” programs in logistics don’t make the operation faster. They make it look busier.

If you’re a logistics manager, that’s not a character flaw. It’s the trap the job sets. You’re measured on fires put out, trucks turned, orders shipped, complaints closed. When the floor is loud and the email inbox is louder, “productive” starts to mean “moving.” It looks like work, not failure.

But when you equate productivity with activity, you accidentally reward the exact behaviors that are costing you: work about work, heroics, rework, and local optimizations that don’t move throughput.

The productivity mistake: counting motion instead of throughput

In freight and supply chain operations, real productivity is output per unit of constrained resource over time. Not keystrokes. Not check-ins. Not “touches.”

Common misreads that feel logical in the moment:

- Measuring productivity by tasks completed (calls, emails, checklists) instead of shipments moved cleanly end-to-end

- Celebrating speed in one department while another absorbs the rework

- “Utilizing” people to 95–100% and then wondering why exceptions pile up

- Treating every load as urgent, which makes none of them flow

What this looks like day-to-day is a lot of motion:

- Updating ETAs in three places because no one trusts the first system

- Reconfirming appointments that were already confirmed

- Copy/pasting tracking updates into customer emails

- Chasing PODs manually because the process isn’t stable

It feels like productivity because people are working hard. The cost shows up as:

- Higher cost-to-serve (labor hours hidden in exception handling)

- Lower throughput (fewer clean loads per planner per day)

- Service inconsistency (some customers get heroics, others get silence)

- Burnout (and then turnover, which restarts the cycle)

The real culprit is “work about work”

Most operations don’t have a people problem. They have a coordination problem.

Work about work is everything you do to manage work instead of doing it. In logistics, it’s often normalized because it prevents immediate failure.

Here are the usual categories:

- Status chasing: checking, pinging, calling “just to be sure”

- Duplicate entry: the same update posted in TMS, spreadsheet, shared inbox, and chat

- Exception triage theater: sorting issues without removing root causes

- Handshake overhead: meetings and approvals that exist because trust in data is low

- Shadow systems: spreadsheets that “run the business” while systems of record lag behind reality

Micro-tasks that drain capacity (and feel unavoidable):

- “Can you resend that rate con?”

- “What’s the latest ETA?” (asked internally after it was already answered)

- “Did the carrier confirm the appointment?” (because confirmations are not visible)

- “Please attach the POD to the ticket.” (because retrieval is manual)

- “Can you update the customer?” (because updates aren’t standardized)

None of these are immoral. They are rational adaptations to weak signals, unclear ownership, and inconsistent process.

Why competent teams normalize it

If you’re thinking, “Sure, but that’s just logistics,” this is where the cost hides.

Competent teams normalize low-grade dysfunction because:

Heroics are rewarded

When a planner pulls a rabbit out of a hat at 4:58 PM, everyone remembers. The system failure that created the urgency is forgotten.

Tribal memory fills process gaps

The operation “works” because a few people know which carrier to call, which dock manager responds, and which customer will blow up. That knowledge isn’t in the workflow; it’s in heads.

Urgency becomes the default setting

When everything is urgent, prioritization disappears. Teams spend the day context-switching, which looks responsive but crushes throughput.

Local optimization feels measurable

It’s easy to count calls, emails, tenders sent, tickets closed. It’s harder to measure end-to-end flow, so leaders default to what’s visible.

The cost is distributed

Rework gets absorbed across planning, customer service, billing, claims, and carrier relations. No single dashboard screams, “This is the tax you’re paying.”

Symptom checklist: are you confusing activity with productivity?

If 3 or more are true, you’re likely paying a productivity tax.

- You have “high utilization” but still miss pickups, appointments, or customer response SLAs

- Planners spend a meaningful part of the day doing status checks versus planning

- The same shipment update is entered or repeated in multiple tools

- Exceptions are handled fast but repeat weekly (same customers, lanes, carriers, facilities)

- New hires take too long to become effective because the job relies on tribal knowledge

The quiet math (conservative and adjustable)

You don’t need a big benchmark study. Use your own operation and conservative assumptions.

Start with one team. Suppose you have:

- 8 people touching shipments (planning + customer updates + exception handling)

- 8 hours/day each

- 220 working days/year

Now assume, conservatively:

- 35 minutes per person per day is spent on duplicate updates, status chasing, and internal clarifications

That’s not a dramatic claim; it’s less than 10% of the day.

Quiet math:

- 35 minutes/day = 0.58 hours/day

- 0.58 hours x 8 people = 4.64 hours/day

- 4.64 hours x 220 days = 1,021 hours/year

Now put a range on it:

- If your fully loaded cost is $35–$60/hour (adjust to your reality)

- Annual productivity tax = 1,021 x $35 to 1,021 x $60

- That’s ~$35,735 to ~$61,260/year for one small team, just from one slice of work about work

That math excludes:

- Service failure costs (expedites, detention, claims, churn risk)

- Billing leakage and rework in AP/AR

- Opportunity cost (loads not moved because attention was consumed)

The point isn’t the exact number. The point is that small, daily frictions compound into real margin.

What “productive” should mean in logistics

Redefine productivity in terms the operation can actually optimize:

- Clean shipments per planner per day (clean = no preventable exceptions)

- Exceptions per 100 loads, by type (appointment, paperwork, tender acceptance, tracking, billing)

- Time-to-resolution for the top 3 exception types

- Customer updates delivered on time with minimal manual effort

- Touches per shipment, with a goal of fewer touches without sacrificing service

A simple litmus test: if you get “more productive” but exceptions and rework don’t drop, you didn’t improve productivity. You accelerated churn.

The hidden bottleneck is usually decision clarity, not labor

Teams rarely fail because they don’t work hard. They fail because:

- Ownership is ambiguous (who owns appointment setting? who owns customer comms?)

- The “definition of done” varies by person and shift

- Signals are noisy (ETAs and statuses are not trusted)

- Priorities are not explicit (everything escalates to the same level)

When those conditions exist, adding tools or pushing for “more output” increases cognitive load. People spend more time coordinating, not moving freight.

30-minute exercise: find your real productivity drain

Do this with one supervisor, one strong planner, and one customer service rep. Set a timer and keep it tight.

Step 1 (10 minutes): Capture the last 10 exceptions

Pull the last 10 shipments that required non-routine intervention (today or yesterday). For each one, write:

- Exception type (appointment, tracking, missed pickup, paperwork, billing, etc.)

- First moment it was detectable

- First moment someone acted

- Tools used (TMS, email, calls, spreadsheets)

- Number of people involved

Step 2 (10 minutes): Count the “work about work” touches

For each exception, list the micro-tasks that were coordination, not resolution. Use bullets:

- internal ping to confirm status

- manual copy/paste update to customer

- re-entering info from email into TMS

- searching for the right contact

- checking two systems to reconcile which is “true”

Then total:

- average coordination touches per exception

- which tool or handoff created the most touches

Step 3 (10 minutes): Pick one lever and define the new standard

Choose one repeatable exception type (not the weird one-off). Define:

- Owner: one role accountable end-to-end

- Trigger: the earliest signal that starts the workflow

- Standard update: what customers/internal teams will receive and when

- Single source: where the status is considered authoritative

- Stop-doing list: one coordination step you will remove this week

If you can’t name the trigger, owner, and standard update in 10 minutes, that’s your bottleneck.

Fixes that actually improve throughput (without demanding heroics)

The goal is not “people work harder.” The goal is “the system requires fewer touches.”

Practical moves:

Reduce duplicate status surfaces

Pick the system of record for shipment status and commit:

- one place to update

- one place to look

- one format for customer-facing updates

If you need a secondary view, make it read-only derived, not manually maintained.

Standardize the top 5 exception playbooks

For the highest-frequency exceptions, define:

- what qualifies as an exception

- who owns it

- the first action

- the customer update template

- the escalation threshold

Create explicit priority rules

Examples (adjust to your network):

- loads within 4 hours of pickup get priority over loads two days out

- service recovery for top-tier accounts gets a defined response window

- new tenders are processed in batch windows, not continuously, unless capacity is constrained

Protect planning time

Schedule two blocks per day where planners are not interrupted unless a defined escalation rule is met. If everything can interrupt planning, planning never happens.

Measure touches, not just outcomes

For two weeks, track:

- touches per shipment

- touches by exception type

You’ll find that a small number of exception categories create most of the coordination load.

“But we already have automation…”

You may. Many teams do. The issue is that automation often stops at the tool boundary and doesn’t resolve trust, ownership, or standards.

Common ways “automation” fails to improve productivity:

- It adds another place to check (now you have one more dashboard)

- It automates alerts without automating decisions (more noise, more triage)

- It doesn’t match how customers measure service (so customer comms stays manual)

- It requires perfect data entry upstream (so exceptions trigger more manual cleanup)

Questions to pressure-test your automation:

- Does it reduce touches per shipment, or just change where the touch happens?

- Does it prevent a repeat exception, or only notify you faster?

- Can a new hire follow it without tribal memory?

- Does it standardize customer updates, or increase the number of “custom” messages?

If automation increases alerts but not clarity, it can lower productivity by raising cognitive load.

What to do next week (not next quarter)

Pick one lane/customer segment and run a contained experiment.

Your weekly plan:

- Monday: Baseline touches per shipment for that segment

- Tuesday: Implement one exception playbook with clear owner and standard update

- Wednesday: Remove one duplicate status surface (stop maintaining a shadow sheet)

- Thursday: Protect one 60-minute planning block from interruptions

- Friday: Review exceptions per 100 loads and touches per exception; adjust one rule

The goal is a small, provable reduction in coordination work. Once you have that, scaling is easier because you can teach it.

The leadership shift: stop rewarding busyness

People will do what gets praised.

- If you praise responsiveness, you get constant context switching.

- If you praise heroics, you get fragile systems.

- If you praise clean flow, you get fewer fires.

The manager move is to make “less work” a win:

- fewer touches

- fewer exceptions

- fewer handoffs

- more predictable updates

- more loads moved cleanly with the same headcount

If you want to talk through where your productivity is leaking (and how to reduce touches without sacrificing service), book a demo here: