When Your Tools Can't Keep Up: Logistics Chaos Story

Tuesday, 16 Dec 2025

|

When Your Tools Can't Keep Up: The Real Story Behind Logistics Chaos

It started on a Tuesday morning, like most days. Mike arrived at the Midwest Freight Solutions office at 6:45 AM earlier than usual. He unlocked the conference room, poured stale coffee, and opened his laptop. Within minutes, the inbox assault began. 847 unread emails. Another day at the logistics firm.

The scene is familiar to anyone running a 3PL, freight brokerage, or forwarding operation. The TMS looks clean. The dashboards are green. The reports are on schedule. But reality? It's somewhere else entirely buried in thousands of customer inquiries, carrier counteroffers, POD requests, and reroute emergencies that exist nowhere in the system.

Sarah, the CEO, had noticed it too. OTIF was slipping (87%, down from 92%). Team morale was flagging. And somehow, after all the software investments, nothing felt faster. "We need AI," she'd told Mike last month. "But where do we even start?"

That question deceptively simple is paralyzing more logistics leaders than they'd admit in a boardroom. It's the entry point problem.

The Universal Logistics Paradox

Here's the uncomfortable truth: Every logistics company, regardless of size, runs on essentially the same two tools. The laptop. The inbox. Everything else TMS, ERP, CRM is supplementary.

The work that actually moves things? The 80% that creates real value and chaos? It lives unstructured and invisible. A carrier calls with a counter rate. That's an email. A driver's detour saves an hour but complicates compliance. That's a Slack message. A customer POD never shows up in the system, triggering six follow-ups. That's a buried email thread. An unexpected delay demands rerouting, negotiation, and customer communication. That's five different platforms, zero coordination.

As we explore in The $2.8B Logistics Email Problem: Why Shared Inboxes Aren't Enough, traditional software companies built beautiful dashboards for the 20% of work that's structured. But they ignored the 80% that lives in the shadows in email, spreadsheets, and chat systems that are technically not part of "the system" at all.

The result? Parallel universes. Your TMS is clean. Your team's reality is chaos. And you're stuck asking, "Which is real? And more importantly, how do we bridge them?"

The Paralysis That Stops AI Adoption

Most logistics leaders we talk to recognize the problem. They've tried band-aids: Better inbox management. More TMS integration. Stricter SOP documentation. Nothing sticks.

Then comes the AI conversation. "We need to automate this," Sarah suggested. "Email handling, POD processing, alert routing." Logical, right?

But here's where it gets stuck. Which emails first? How many are worth automating? What's the real ROI? Where does the biggest pain live and is it even measurable?

The answer, honest one, is they don't know. Not because they're unsophisticated. But because you can't optimize what you can't see. And you can't see what exists in 5,000 daily emails sent to shared inboxes with no tracking, no taxonomy, no structure.

A Different Approach: The Investigator Model

Mike was skeptical when he first heard the term "inbox investigator." It sounded like corporate jargon. But the promise was different: Don't ask what needs automating. Audit what's actually happening. Let the chaos speak for itself.

The approach was simple: Send a week's worth of incoming emails the raw, unfiltered stream to an AI system designed not to automate, but to understand. Measure. Quantify. Diagnose.

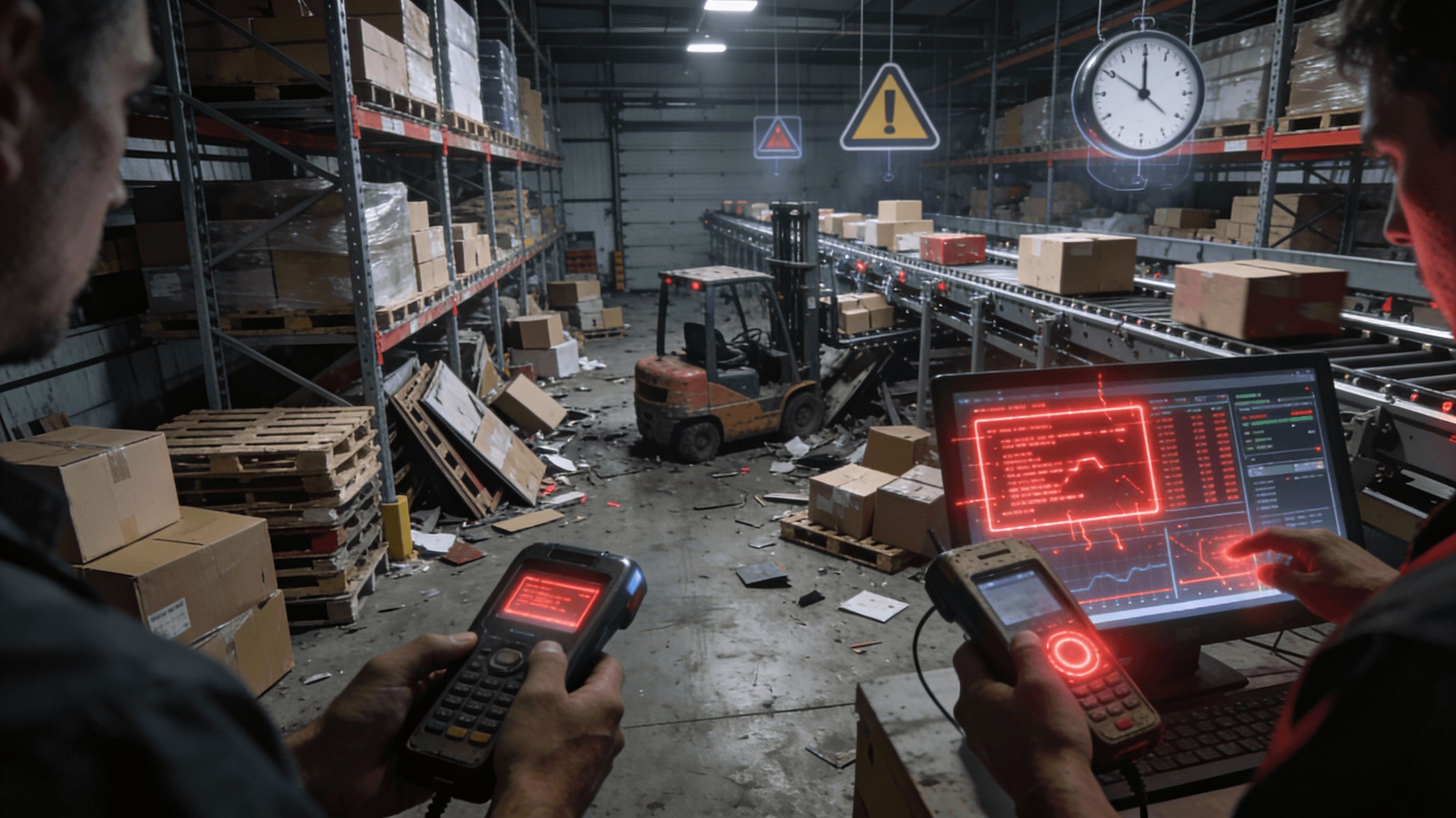

One week. 2,100 emails. And the results were astonishing.

The system didn't just count emails. It categorized them using proprietary diagnostic tools (similar to the Mess-O-Meter framework). It measured time investment. It mapped pain patterns. And it translated chaos into insight:

68% of emails were automatable (that's 1,428 conversations that didn't need humans).

4.2 hours per day were wasted on repetitive requests: "Where's my load?" (32% of traffic), "Do you have the POD?" (24%), "Can you explain this charge?" (19%).

$2.8 million annually leaked through SLA misses, OTIF penalties, and inefficient handling.

For the first time, the chaos had a number. And that number made the business case undeniable.

From Insight to Action: The 90-Day Transformation

But here's what surprised Mike most: The insight was only half the value. The second half was clarity on what to automate first, and in what order. As detailed in our 90-Day AI Agent Roadmap, the system ranked priorities by impact, not just by volume.

ETA requests (high volume, low complexity) automated first. Then POD extraction. Then dispute detection. Each layer built on the last.

Month 1: Quick Wins

The first AI agent a simple one just answered ETA requests by hitting the TMS API and replying with tracking links. 82% deflection rate. That freed 1.8 hours per day, per person, across the ops team. This kind of rapid response is what we detail in Hands-Free Logistics Inbox: AI Triage Best Practices 2025.

"I stopped getting 'Where's my load?' messages," Mike told Sarah. "Not because drivers got better. Because the AI got there first."

Month 2: Orchestration

By week 5, multiple agents were working together. Email came in, got categorized, routed to the right agent, took action, notified stakeholders, and updated TMS all without a human touching it. Disputes (which used to require manager escalation) got analyzed for margin impact and routed with recommendations.

The principles behind this orchestration are explored in Multi-Agent AI via Email: End-to-End Automation for Logistics Complexity.

The team noticed something odd: They stopped saying "I'm drowning." They started saying, "I actually have time to think."

Month 3: Strategic Autonomy

By month three, the agents stopped just reacting. They started predicting. The system noticed I-80 accidents on Tuesdays. Proactively re-routed Chicago loads. Flagged weather patterns. Identified carrier performance trends automatically.

OTIF jumped to 96.4%. Not because the team got smarter. Because the invisible work the stuff that used to happen in scattered emails and individual memories finally had visibility and orchestration. This is what true AI Agent Maturity Assessment looks like in practice.

The Real Story: It's Not About Technology

Here's what Mike understood by the end: This wasn't a technology story. It was a diagnosis story.

The AI investigator wasn't selling him automation. It was showing him a mirror. "This is what chaos actually looks like. This is where your people are really spending time. This is what's slipping through the cracks."

Once he saw it, everything else made sense. The priorities became obvious. The ROI became real. The team's resistance transformed into ownership (because they were solving problems they could finally see, not problems a consultant told them existed).

For deeper context on how logistics firms typically uncover these opportunities, check out Freight Brokerage Email Automation: From Manual to AI in 90 Days.

Your Entry Point

If you're reading this, you've probably felt it: The sense that your software is incomplete, that the real work happens elsewhere, that something's off between what the dashboard says and what your team experiences.

You're not wrong. And you're not alone.

The entry point isn't a fancy platform or a complete overhaul. It's the same one Mike found: Honest diagnosis. Audit your inbox. Measure your chaos. Make it visible. Then, and only then, decide what to automate and in what order.

Because here's the paradox: The companies that AI helps most aren't the ones with the best systems. They're the ones honest enough to measure the gaps in theirs.

What Happens Next

For Mike and Midwest Freight Solutions, the journey didn't end at month three. The agents kept learning. The processes kept improving. The team stopped fighting fires and started managing operations. Learn more about sustaining this momentum in Supply Chain Visibility Through AI Email Intelligence.

But the real win? Headcount stayed flat. Revenue grew 41%. And the inbox—that eternal symbol of chaos finally became manageable.

Your inbox is telling you the same story. The question is: Are you ready to listen?

External Resources & Case Studies

To explore industry trends and benchmarks:

- Talking Logistics Top 10 Posts in 2025 : Real-world logistics case studies and trends

- Top 50 Transportation & Logistics Blogs : Industry voices on supply chain automation

- LinkedIn Logistics & Supply Chain Insights : Deep dives on narrative logistics and AI adoption

Ready to uncover what's actually happening in your logistics operation? Book a free inbox audit to see your specific chaos metrics, priorities, and the path to your 90-day transformation. No obligation. Just clarity.

Book your inbox audit and discover where your $2.8M is hiding.