The Zero-Waste Warehouse: AI Solutions for Dead Stock and Layout Optimization

Sunday, 3 Aug 2025

|

In logistics, some losses are visible—damaged goods, theft, missed deliveries. Others are silent profit killers.

Two of the biggest? Dead stock that clogs your shelves and inefficient warehouse layouts that force your pickers to walk miles for a single order.

Both problems quietly drain profitability, slow down order fulfillment, and inflate operational costs. But AI is now giving warehouse operators a data-driven, zero-waste playbook to fix them.

The Cost of Dead Stock and Poor Layout

Dead Stock:

Inventory that doesn’t sell ties up working capital, takes up valuable storage space, and risks obsolescence.

Inefficient Layout:

Every extra step a picker takes is wasted time, wasted labor cost, and delayed order delivery. Across thousands of picks per month, these inefficiencies add up to serious losses.

How AI Creates a Zero-Waste Warehouse

An AI Warehouse Optimization Agent works in two parallel streams—eliminating dead stock and optimizing warehouse layout.

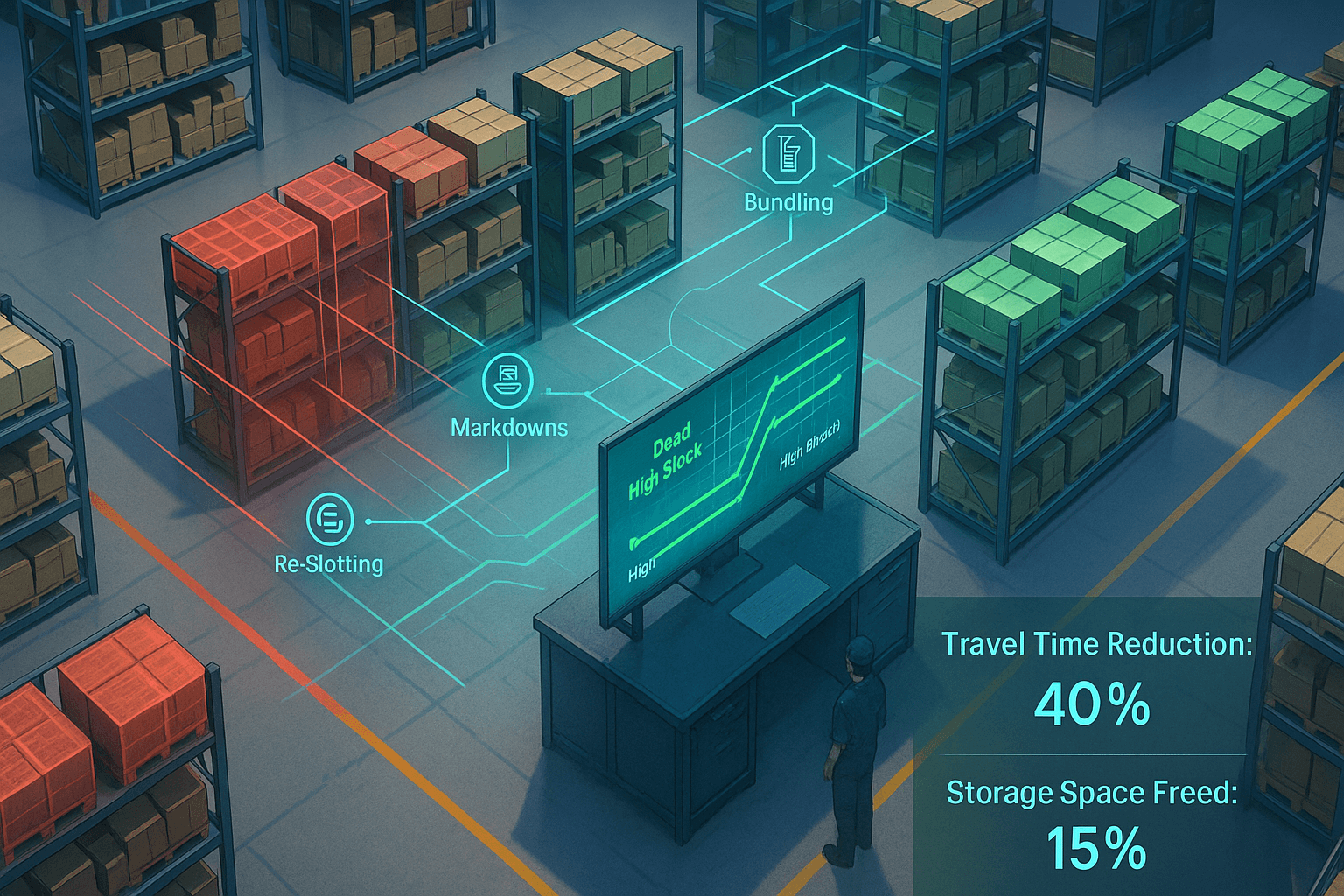

1. Identifying and Moving Dead Stock

AI analyzes historical sales, demand trends, and seasonal cycles to flag slow-moving inventory before it becomes obsolete.

- Suggests markdown strategies to move products faster.

- Recommends bundling slow movers with high-demand products.

- Predicts optimal reorder quantities to prevent overstock (see how AI supports real-time inventory management).

2. Optimizing Layout for Speed

Using pick-and-pack data, AI identifies travel time between SKUs and high-frequency order patterns. It can:

- Recommend re-slotting popular items closer to packing stations.

- Create zone-based picking to minimize walking.

- Dynamically adapt layouts as demand changes (agentic AI warehouse automation).

Workflow: From Data to Action

Data Ingestion – AI integrates with your WMS, POS, and eCommerce platforms.

Dead Stock Detection – Flags SKUs with declining demand or extended shelf time.

Layout Simulation – Runs digital “what-if” scenarios to test new slotting strategies before implementation (self-optimizing warehouse AI).

Recommendation & Execution – Outputs a clear action plan for markdowns, re-slotting, and replenishment schedules.

The ROI of Zero-Waste Warehousing

By implementing AI-driven warehouse optimization, operators can:

- Free up 10–20% of storage space without expansions.

- Cut picker travel time by up to 40%.

- Reduce working capital tied up in excess inventory.

- Improve order accuracy and fulfillment speed.

When combined with AI-driven fraud prevention and inventory protection (AI warehouse fraud prevention), the operational gains compound.

From Hidden Costs to Visible Profits

Your warehouse can be more than a cost center—it can be a profit amplifier. By eliminating dead stock and reengineering layouts, AI turns wasted space and wasted time into bottom-line growth.

Book a demo today to see how Debales AI can help you design a zero-waste warehouse that’s faster, leaner, and more profitable.

👉 https://debales.ai/book-demo

All blog posts

View All →

Saturday, 28 Feb 2026

Stop Paying Accessorials You Didn't Approve

Detention and accessorial charges keep slipping through. Learn why it happens, what the data says, and how to prevent bad bills this week.

Saturday, 28 Feb 2026

Why accessorials keep wrecking your freight margin

Accessorial charges are eating freight margins via bad data, weak processes, and missed documentation. Here is how ops teams can stop the bleed fast.

Saturday, 28 Feb 2026

Why freight exceptions keep ambushing your team

Freight exceptions keep burning time and margin. Learn why they repeat, what the data says, and a practical weekly playbook to reduce chaos fast.