A Simple Analogy for How AI Optimizes a Supply Chain?

Friday, 26 Sep 2025

|

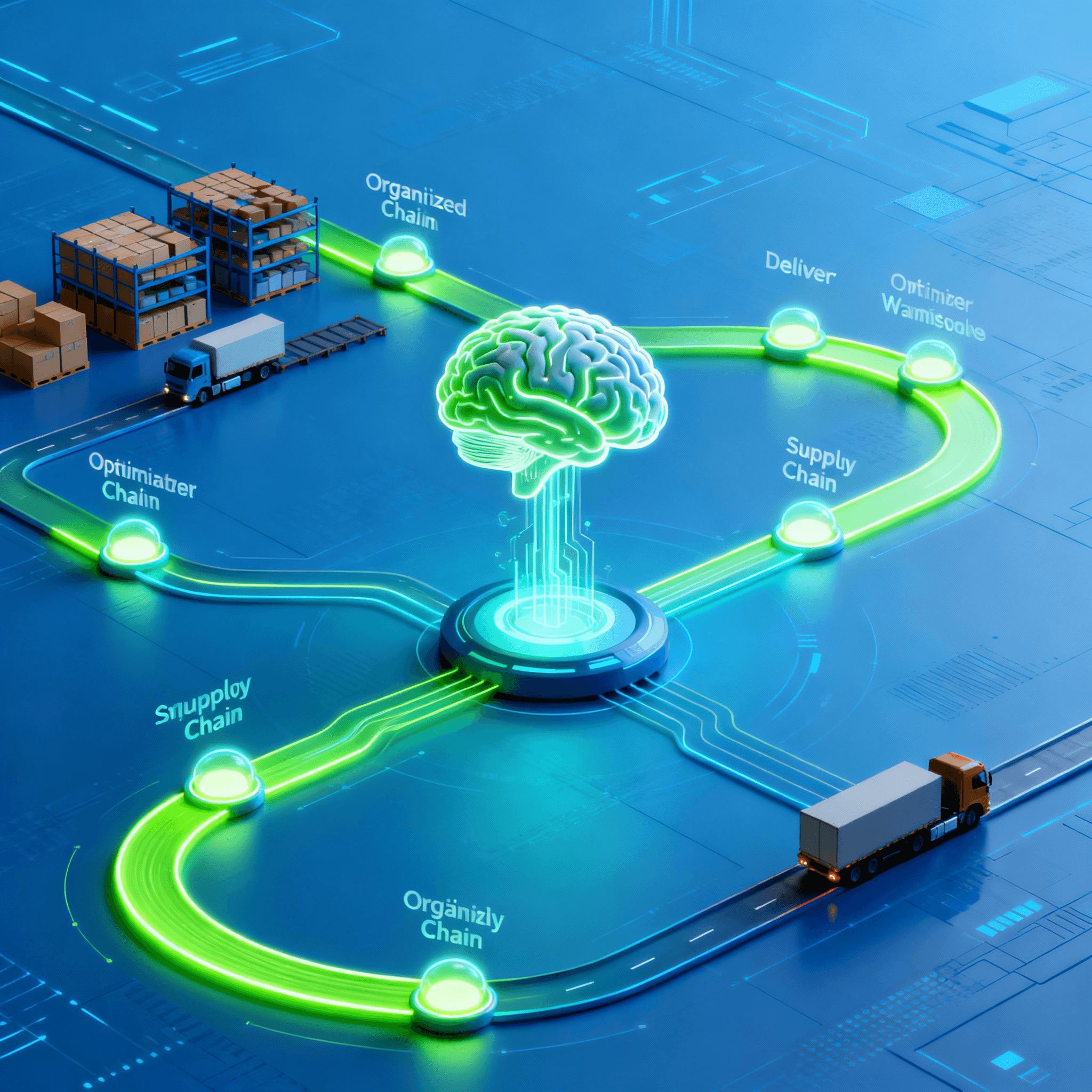

A Simple Analogy for How AI Optimizes a Supply Chain

Explaining how AI optimizes a supply chain doesn't require a computer science degree. In fact, the best way to understand this transformation is through everyday analogies that reveal the intelligence, adaptability, and foresight AI brings to logistics operations.

Let's explore how AI works in supply chains using comparisons everyone can grasp—from GPS navigation to weather forecasting—and discover why this technology represents a fundamental shift in operational capability.

Ever wondered how machines make supply chains smarter? These simple analogies will change how you think about logistics AI.

The GPS Analogy: AI as Your Supply Chain Navigator

Think of traditional supply chain management as driving with a paper map. You plan your route before leaving, but if traffic jams occur or roads close, you're stuck following the original plan or manually figuring out alternatives on the fly.

AI-powered supply chain management is like having Google Maps or Waze. It continuously monitors real-time conditions—traffic (demand fluctuations), road closures (supplier disruptions), accidents (port delays), and weather (market conditions)—then automatically recalculates the optimal route to get you to your destination faster and more efficiently.

Just as GPS saves time and fuel by avoiding congestion, AI optimizes inventory flows, transportation routes, and resource allocation by continuously adapting to changing conditions.

Real-world impact:

- Dynamic route optimization reduces delivery times by 20-30%

- Real-time rerouting minimizes disruption impact by 40-50%

- Fuel cost reductions of 15-25% through intelligent routing

For deeper insights into route optimization algorithms, explore Most Common AI Algorithms Used for Route Planning and Demand Forecasting.

The Weather Forecast Analogy: Predicting Before Problems Strike

Traditional supply chains react to problems after they occur—like getting caught in a rainstorm without an umbrella because you didn't check the weather forecast.

AI-powered supply chains predict disruptions before they happen—like checking tomorrow's weather and bringing an umbrella proactively. AI analyzes patterns from historical data, current conditions, and external signals (economic indicators, weather patterns, geopolitical events) to forecast demand spikes, supply shortages, and potential delays days or weeks in advance.

Business benefits:

- Demand forecasting accuracy improves by 20-50%

- Inventory costs reduced by 20-35% through better prediction

- Lost sales reduced by up to 65% by anticipating stockouts

This predictive capability is detailed in How Predictive Analytics Works for Logistics.

The Chess Grandmaster Analogy: Thinking Many Moves Ahead

A novice chess player reacts to each move individually. They make decisions based solely on the current board position without anticipating future consequences.

A chess grandmaster thinks several moves ahead, considering multiple scenarios simultaneously and choosing strategies that optimize long-term outcomes rather than just immediate gains. This is exactly how AI optimizes supply chains.

AI doesn't just solve today's inventory imbalance or tomorrow's delivery schedule—it simulates hundreds of future scenarios to find strategies that balance competing objectives: minimizing costs while maximizing service levels, optimizing inventory while reducing waste, and improving delivery speed while cutting fuel consumption.

Strategic advantages:

- Multi-variable optimization across competing objectives

- Scenario planning for risk mitigation

- Long-term capacity planning aligned with business goals

Learn how this strategic thinking applies to warehouse operations in What's the Difference Between AI, Machine Learning, and Automation in a Warehouse Context?.

The Personal Assistant Analogy: Automating the Routine, Elevating the Strategic

Traditional supply chain management requires teams to manually handle countless repetitive tasks: checking inventory levels, tracking shipments, responding to customer inquiries, processing documents, and coordinating with suppliers.

AI acts like having a brilliant personal assistant for every function—one that never sleeps, never makes transcription errors, and learns to anticipate needs before you ask. AI automates documentation processing, shipment tracking, customer communication, and routine decision-making, freeing human teams to focus on strategic initiatives.

Operational efficiency gains:

- Documentation processing time reduced by 70-80%

- Customer response times cut from hours to seconds

- Manual data entry errors reduced by 90%+

Discover how AI automates communication in How Natural Language Processing (NLP) Applies to the Logistics Industry.

The Orchestra Conductor Analogy: Harmonizing Complex Operations

A supply chain without AI is like musicians playing independently—each doing their part but without perfect coordination. Inventory, warehousing, transportation, and customer service operate in silos with limited visibility into how their decisions impact other functions.

AI acts as the orchestra conductor, ensuring every section (procurement, warehousing, transportation, customer service) performs in perfect harmony. It synchronizes activities across the entire supply chain, balancing inventory levels with demand forecasts, coordinating warehouse capacity with inbound shipments, and aligning transportation resources with delivery commitments.

Coordination benefits:

- End-to-end supply chain visibility

- Synchronized cross-functional decision-making

- Reduced waste through better coordination

- Improved customer satisfaction through consistent execution

This holistic coordination mirrors the capabilities described in What is a Digital Twin and How is it Used in Logistics AI?.

The Vision Enhancement Analogy: Seeing What Humans Cannot

Human supply chain managers see patterns in dozens of variables. AI sees patterns in millions of data points simultaneously—detecting subtle correlations, seasonal trends, and early warning signals invisible to human analysis.

It's like comparing human vision to thermal imaging cameras that reveal heat patterns invisible to the naked eye. AI uncovers insights hidden in vast data volumes, enabling decisions based on comprehensive intelligence rather than limited observations.

Data intelligence advantages:

- Analysis of millions of data points in real-time

- Detection of subtle patterns across complex variables

- Early warning systems for emerging disruptions

- Continuous learning and improvement from every transaction

Learn about AI's visual capabilities in How Computer Vision Technology Helps in Logistics Operations.

How debales.ai Brings These Analogies to Life

At debales.ai, we've built an AI platform that embodies all these analogies:

Navigation Intelligence: Dynamic routing and resource optimization that adapts to real-time conditions

Predictive Foresight: Demand forecasting and risk detection that anticipates problems before they occur

Strategic Thinking: Multi-objective optimization balancing cost, speed, quality, and service

Automation Excellence: AI agents handling routine tasks with superhuman accuracy and speed

Orchestration Capability: End-to-end coordination across warehouse, transportation, and customer service

Enhanced Vision: Pattern recognition across millions of data points revealing hidden opportunities

For a comprehensive view of AI's role in logistics, visit What Exactly Is AI in Logistics and Supply Chain Management?.

The Bottom Line: From Analogy to Action

While analogies help explain AI's value, the real proof lies in measurable business outcomes:

- 15% lower logistics costs for early AI adopters

- 35% improved inventory levels through predictive optimization

- 20-50% reduction in supply chain errors

- 25-40% increase in customer satisfaction

These aren't theoretical benefits—they're transformation metrics achieved by organizations embracing AI-powered supply chain optimization.

Ready to transform your supply chain from reactive to predictive, from siloed to orchestrated, from manual to intelligent?

Discover how debales.ai's AI-powered platform turns these analogies into operational reality—delivering measurable improvements in cost, efficiency, and customer satisfaction.

Book a demo with debales.ai today and experience supply chain optimization reimagined.

All blog posts

View All →

Monday, 2 Mar 2026

Why freight exceptions keep blowing up your week

Freight exceptions keep turning into fire drills. Learn why they repeat, what data is changing in logistics, and steps to cut churn this week.

Monday, 2 Mar 2026

Stop Losing Margin to Accessorial Charges You Miss

Accessorials are quietly eating your freight margin. Learn why they keep slipping through and how to catch, dispute, and prevent them this week.

Monday, 2 Mar 2026

Why freight exceptions keep blindsiding your team

Freight exceptions keep popping up because data and workflows are fragmented. Learn a practical way to cut dwell time, detention, and rework fast.