AI Exception Management for Freight Operations Teams

Monday, 16 Feb 2026

|

Hook opening

A single late pickup can trigger 20 to 40 messages across email, calls, and chat before anyone agrees on the next step. If you have ever watched a simple ETA slip turn into a full-blown fire drill across dispatch, customer service, and the warehouse, you already know the real cost is not just the late load. It is the time your team loses trying to find the truth.

The problem (what's broken and why)

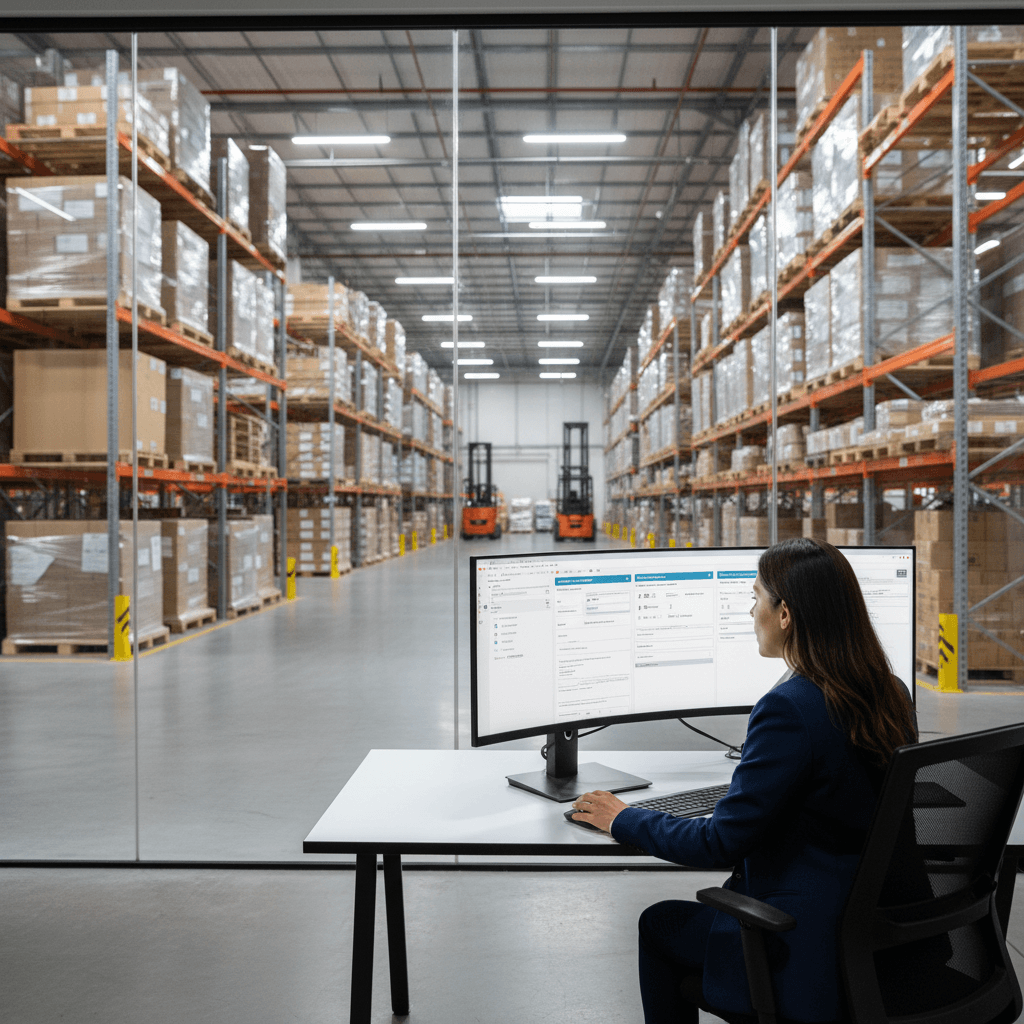

Freight operations are still run on fragmented signals.

- The TMS has the load plan, but not always the latest appointment change.

- The WMS has dock activity, but not the carrier's real-time status.

- The ERP has customer requirements, but not the exceptions in motion.

- Emails and carrier portals hold critical updates that never make it into systems of record.

That fragmentation creates two predictable failure modes.

First, exceptions are detected late. By the time someone sees that a driver missed a check-in window or that an LTL shipment was reweighed and reclassified, the recovery options are limited.

Second, exceptions are worked manually. Ops teams copy and paste updates into the TMS, chase PODs, reconcile BOLs, and explain the same delay to sales and the customer multiple times. You end up paying for premium freight, detention, and chargebacks, plus the hidden labor cost of constant follow-up.

Industry context (data and trends)

Most logistics leaders are dealing with more volatility, not less.

- Appointment-based operations have increased across DCs and cross-dock facilities, which raises the penalty for missed time windows.

- Visibility data is more available than ever, but it is spread across ELD feeds, telematics, carrier APIs, and broker updates. More data has not automatically meant faster decisions.

- Shippers are tightening OTIF expectations, and many are pushing scorecards down to carriers and 3PLs with financial consequences.

What does that mean on the floor? Exception volume rises as complexity rises. Multi-stop FTL routes, drayage handoffs at ports, and pooled LTL networks all introduce more points of failure. When your team is managing exceptions through inbox searches and tribal knowledge, you are effectively scaling risk.

The solution approach

AI exception management is not about replacing your TMS or WMS. It is about building a layer that detects issues early, classifies them correctly, and routes the right task to the right person.

A practical approach looks like this.

- Consolidate operational signals

- Pull planned data from TMS and appointment systems - Pull execution data from tracking, ELD, carrier status updates, and warehouse check-in logs - Ingest unstructured data like emails, PDFs, and portal notes that contain the real story

- Define exception types that match how you actually work

- Late pickup risk, late delivery risk - Missed appointment, reschedule needed - Detention risk, dwell time over threshold - POD missing, BOL mismatch, invoice dispute risk - Accessorials likely, such as lumper, redelivery, reweigh

- Add decision logic and SLAs

- If ETA slips by more than 45 minutes and appointment is within 2 hours, flag as high priority - If dwell exceeds 60 minutes at a shipper, prompt detention documentation steps - If POD is not received within 24 hours of delivery, trigger a carrier follow-up workflow

- Automate the first 60 percent of the work

- Draft customer updates with the latest verified data - Open tasks in your TMS or ticketing tool - Request missing documents and attach them to the right load

- Keep humans in control for high-impact decisions

- Expediting, repower, mode conversion, or appointment negotiations still need judgement - AI should surface options with cost and service trade-offs so the operator can choose

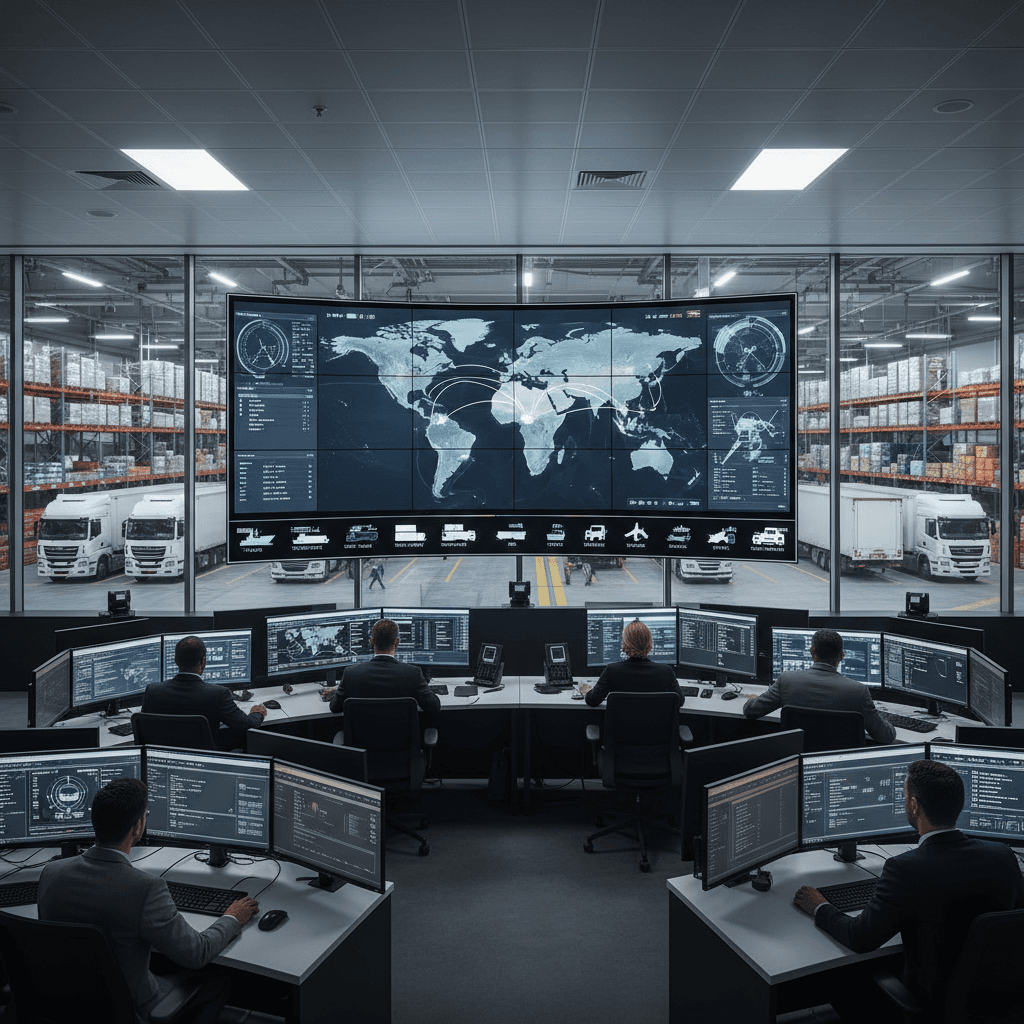

A quick example from a 3PL control tower

A shipper has a strict delivery appointment at a retail DC. The carrier's last check call says the driver is on time, but ELD indicates they stopped 90 minutes ago and have not moved. AI correlates this with historical congestion on that lane, flags a late delivery risk, and creates a task for the account team to request a reschedule while there is still appointment availability. Instead of discovering the problem at the gate, you act while you still have leverage.

How Debales.ai helps

Debales.ai helps operations teams turn scattered updates into structured, actionable exceptions. It can ingest messages, documents, and system events, then categorize issues like late pickup risk, missing POD, or accessorial exposure. The goal is simple: fewer manual touches per load and faster resolution when something breaks.

For teams living in a mix of TMS workflows, carrier portals, and shared inboxes, Debales.ai can reduce time spent searching and summarizing so operators can focus on recovery actions that protect OTIF and margins.

Actionable takeaways for logistics managers and 3PL leaders

- Map your top 10 exceptions and quantify the labor

Pick the exceptions that generate the most touches per load, like appointment changes, POD chasing, and detention. Track how many minutes are spent per event for two weeks. You cannot improve what you do not measure.

- Set clear thresholds for early warning

Do not wait for a shipment to be late to call it a problem. Define triggers like ETA slip thresholds, dwell time limits, and document due times. Put those triggers where your team actually works.

- Standardize your exception playbooks

For each exception type, document the required data, the next best action, and who owns it. A playbook that fits on one screen beats a 30-page SOP nobody opens.

- Automate customer updates without losing control

Use templates that include load number, PRO, stop details, and updated ETA. Make sure updates are grounded in verified data sources, not optimism.

- Close the loop into billing

Many margin leaks start as operational misses. Tie detention documentation, lumper receipts, and POD capture to billing workflows so you do not fight the same battle 30 days later.

- Start with one lane, one customer, or one team

A pilot should be narrow enough to measure. For example, focus on retail appointment freight or drayage moves where handoffs are frequent. Prove reduced touches per load and faster exception resolution, then scale.

Strong closing

Freight operations will always have exceptions. Weather changes, warehouses get backed up, and carriers run into real-world constraints. The difference between a resilient operation and a chaotic one is how quickly you detect the issue and how consistently you respond.

If your team is spending more time hunting for updates than fixing problems, AI-driven exception management is a practical next step. It turns noise into prioritized actions, reduces repeat follow-ups, and helps you protect service while keeping costs under control. The best part is you do not have to rebuild your stack to get there. You just need to stop letting exceptions live in inboxes.