Automate BOL and POD Processing for Faster Billing

Monday, 16 Feb 2026

|

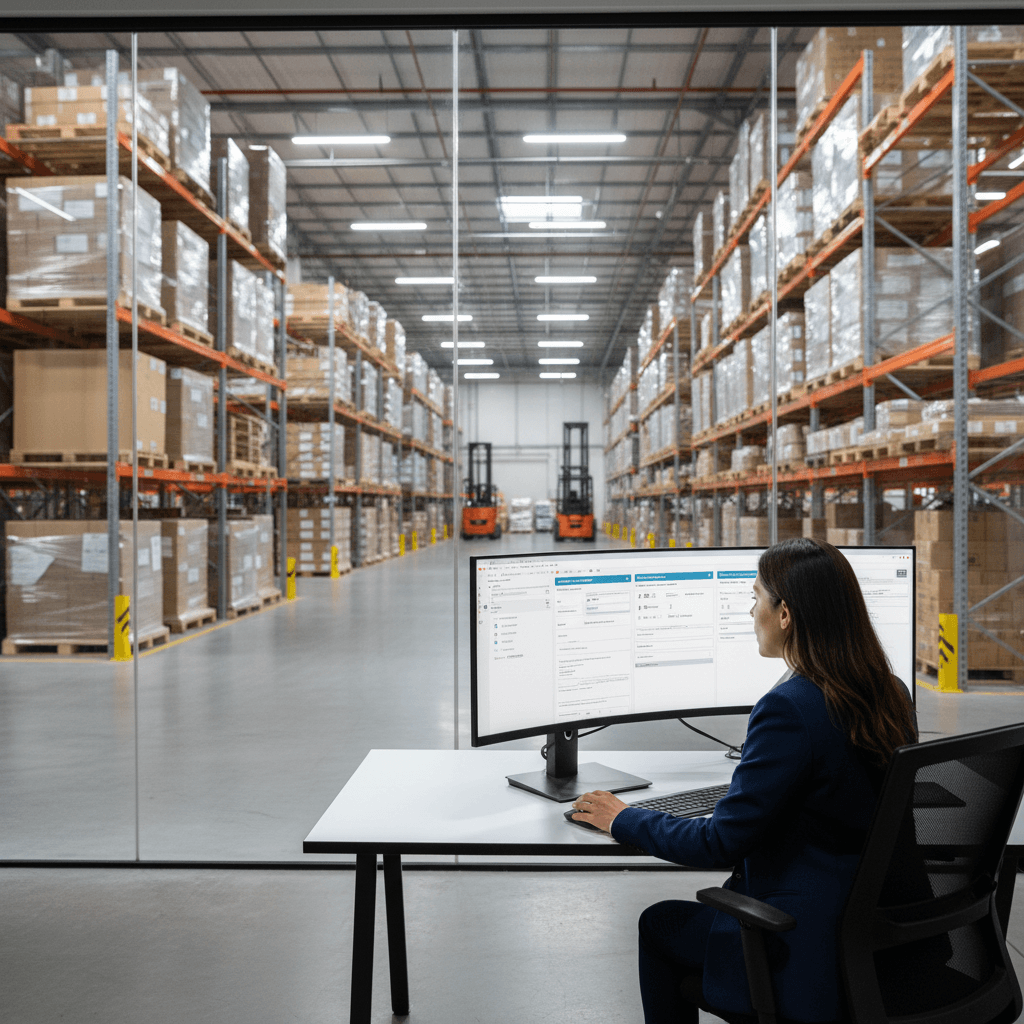

Hook opening

A single missing POD can hold up an entire invoice. If you are running a busy 3PL or brokerage desk, that means one late upload can delay billing, slow cash flow, and trigger a customer email thread that eats half your morning. Sound familiar? Now multiply it by 50 loads a day, across LTL, FTL, drayage, and final mile.

The problem

BOLs, PODs, lumper receipts, accessorial approvals, and detention timestamps are still handled like it is 2009. Documents arrive from everywhere: carrier portals, driver photos, email, EDI, shipper systems, and random shared inboxes. Then the team:

- Renames files

- Matches them to the right load

- Checks for signatures, timestamps, and exceptions

- Updates the TMS

- Pushes to ERP or customer portals

- Waits for approvals before billing

What is broken is not effort. It is the workflow design.

1) Data is trapped in unstructured formats A POD photo is not “data” to a TMS. Neither is a scanned BOL. If your process depends on humans reading and rekeying, you will get delays and errors.

2) Exceptions are hard to spot early Late delivery, OS and D shortages, temperature deviations, or damaged freight often show up in notes or handwritten marks. If they are discovered after invoicing, you get disputes, short pays, or chargebacks.

3) Teams become the integration layer Ops coordinators end up acting like middleware between TMS, WMS, and ERP. That is expensive, fragile, and hard to scale in peak season.

Industry context

Documentation pressure is increasing, not decreasing.

- More shippers require near real-time visibility and document upload within tight SLAs, often 2 to 24 hours after delivery.

- Accessorial billing scrutiny is higher. Detention, layover, lumper, and TONU charges are increasingly denied without clean supporting documentation.

- Freight networks are more complex. A single order may involve cross-dock, multi stop, drayage plus transload, and a final LTL leg. Each handoff generates more paperwork.

Operationally, this shows up as back office load. Many teams still spend minutes per shipment just to gather documents and validate them. At 300 shipments per week, even 6 minutes of document handling per load is 30 hours of work. That is almost a full time role spent on moving PDFs around.

The solution approach

The goal is not to “digitize documents.” The goal is to compress the order-to-cash cycle by turning documents into structured, validated shipment events.

1) Centralize intake from every channel

Create one ingestion layer for:

- Email attachments and forwarded driver messages

- Carrier portal downloads

- EDI 210 and EDI 214 attachments

- Mobile uploads from drivers

- Customer portals and SFTP drops

If your process depends on people checking five inboxes, you are already behind.

2) Extract the fields that matter

For BOL and POD workflows, the most useful fields are usually:

- PRO or tracking number

- BOL number

- PO and order references

- Consignee name and delivery address

- Delivery date and time

- Signature presence and name, when available

- Seal numbers for FTL

- Accessorial evidence: detention times, lumper amounts, notes

Once extracted, these fields can be used to match to the correct load in the TMS, even when filenames are inconsistent.

3) Validate before billing

Build simple checks that stop disputes early:

- POD must include a signature or an approved exception code

- Delivery timestamp must be present for time definite freight

- Lumper receipt required if lumper is billed

- Detention requires arrival, in gate, out gate, and supporting proof

These validations create clean invoice packets and reduce rework.

4) Automate routing and approvals

Not every document needs the same path.

- Clean POD with no exceptions can auto-attach to the load and trigger billing readiness.

- POD with damage notes can route to claims or customer service.

- Detention documentation can route to the shipper contact for approval before invoicing.

This is where you cut cycle time, because you stop treating every load like a special case.

5) Close the loop in TMS and ERP

The best automation does not just store documents. It updates statuses and pushes the right metadata into your systems:

- TMS: delivery confirmed, POD received, accessorial approved

- ERP: invoice ready, required backup attached, exception flags

- Customer portal: packet assembled, visible without manual upload

How Debales.ai helps

Debales.ai helps operations teams automate document intake, data extraction, and load matching for common freight paperwork like BOLs, PODs, lumper receipts, and detention proofs. Instead of having coordinators read PDFs and update the TMS by hand, Debales.ai can capture key fields, validate required elements, and route exceptions to the right queue.

Teams typically use it to shorten the time between delivery and invoice readiness by removing repetitive steps like renaming files, chasing missing signatures, and manually building invoice packets. The result is a cleaner back office workflow that scales when volume spikes.

Actionable takeaways

Here are practical moves you can make in the next 30 days.

1) Measure your current document cycle time

Track two timestamps for a sample of loads:

- Delivery completed

- POD received and attached to the load in TMS

If the median is more than 24 hours, you likely have an intake or matching problem.

2) Standardize what “bill ready” means

Write a one page checklist by mode.

- LTL: POD plus accessorial receipts

- FTL: signed POD, seal confirmation if required

- Drayage: in gate, out gate, interchange, and appointment proof

Then enforce it in workflow. Clarity reduces disputes.

3) Create an exception taxonomy

Stop using “missing docs” as a bucket. Break it into:

- Missing signature

- Missing timestamp

- Wrong load reference

- Illegible image

- Customer approval needed

When you classify exceptions, you can fix the root causes.

4) Reduce channels, then automate the rest

If carriers send PODs via email, portal, and text messages, pick a primary channel and publish it. Then automate ingestion for the holdouts.

5) Start with your top 20 percent customers

The biggest gains usually come from high volume accounts with strict requirements. Automate there first, then roll out to the long tail.

Strong closing

Freight ops is hard enough without a manual paperwork treadmill slowing down billing. If your team is spending hours matching PODs to loads, chasing lumper receipts, and rebuilding invoice packets, the real issue is that your documents are not connected to your data.

Fix the intake. Extract the fields. Validate before billing. Route exceptions automatically. When BOL and POD processing becomes a structured workflow instead of a daily scramble, you will see faster invoicing, fewer disputes, and a back office that can handle growth without adding headcount.