AI Skills Gap: Make-or-Buy Analysis for Logistics Talent and Partnerships

Friday, 31 Oct 2025

|

Introduction: Navigating the AI Talent Dilemma in Logistics

The AI skills gap in logistics widens with 70% of organizations lacking internal expertise for AI implementation, necessitating a make-or-buy analysis to balance building capabilities through training against acquiring via strategic partnerships for faster ROI. This decision framework evaluates costs, timelines, and scalability for talent acquisition, upskilling programs, and tech collaborations, enabling 25-40% efficiency gains without overextending resources. By weighing internal development's long-term ownership against partnerships' immediate access, firms address the 50% shortfall in AI-proficient logistics talent projected for 2025.

For HR leaders, CIOs, and supply chain executives, this analysis aligns with demands for AI-driven operations handling $10T in global trade, ensuring competitive agility. This guide explores the gap's implications, make-or-buy criteria, strategies for each path, hybrid models, and a practical roadmap to close it effectively. Strategic choices here yield 3-5x returns in innovation and cost savings.

The AI Skills Gap: Challenges in Logistics

Logistics faces an acute AI skills shortage, with only 30% of teams skilled in areas like machine learning for predictive routing, leading to 20% underutilization of AI tools and delayed projects. This gap stems from rapid AI evolution outpacing traditional training, exacerbating issues like data silos and integration failures that cost firms 15% in inefficiencies. External factors, including talent poaching by tech giants, inflate hiring premiums by 40%, straining budgets for specialized roles in AI ethics and automation.

Without resolution, organizations risk 60% failure rates in AI initiatives, undermining resilience in volatile supply chains. The make-or-buy lens provides clarity, assessing whether internal investment or external alliances better bridge this divide.

Make-or-Buy Analysis: Core Considerations

A make-or-buy evaluation compares internal builds—fostering ownership and customization—with buys via partnerships that offer speed and expertise without heavy upfront costs. Key metrics include time to competency (internal: 12-18 months vs. partnerships: 3-6 months), total costs (training: $50K-200K per employee vs. vendor fees: 20-30% of project value), and scalability for logistics' dynamic needs. Risk assessment weighs internal control over IP against dependency on partners for cutting-edge updates.

For talent acquisition, "make" suits retaining domain knowledge, while "buy" accelerates with consultants filling immediate gaps. This analysis guides decisions, prioritizing alignment with organizational maturity and strategic goals.

Factors Influencing the Decision

- Cost Structure: Internal training yields 2-3x long-term savings but requires $1-5M initial outlay; partnerships capex at 10-20% with opex models.

- Timeline Pressures: Urgent AI needs favor buys for rapid deployment, avoiding 6-12 month internal ramps.

- Core Competency Fit: Build for logistics-specific AI like route optimization; buy for niche tech like quantum integration.

- Scalability and Flexibility: Partnerships enable quick scaling during peaks, while internal builds ensure sustained adaptability.

These elements ensure tailored strategies that maximize value.

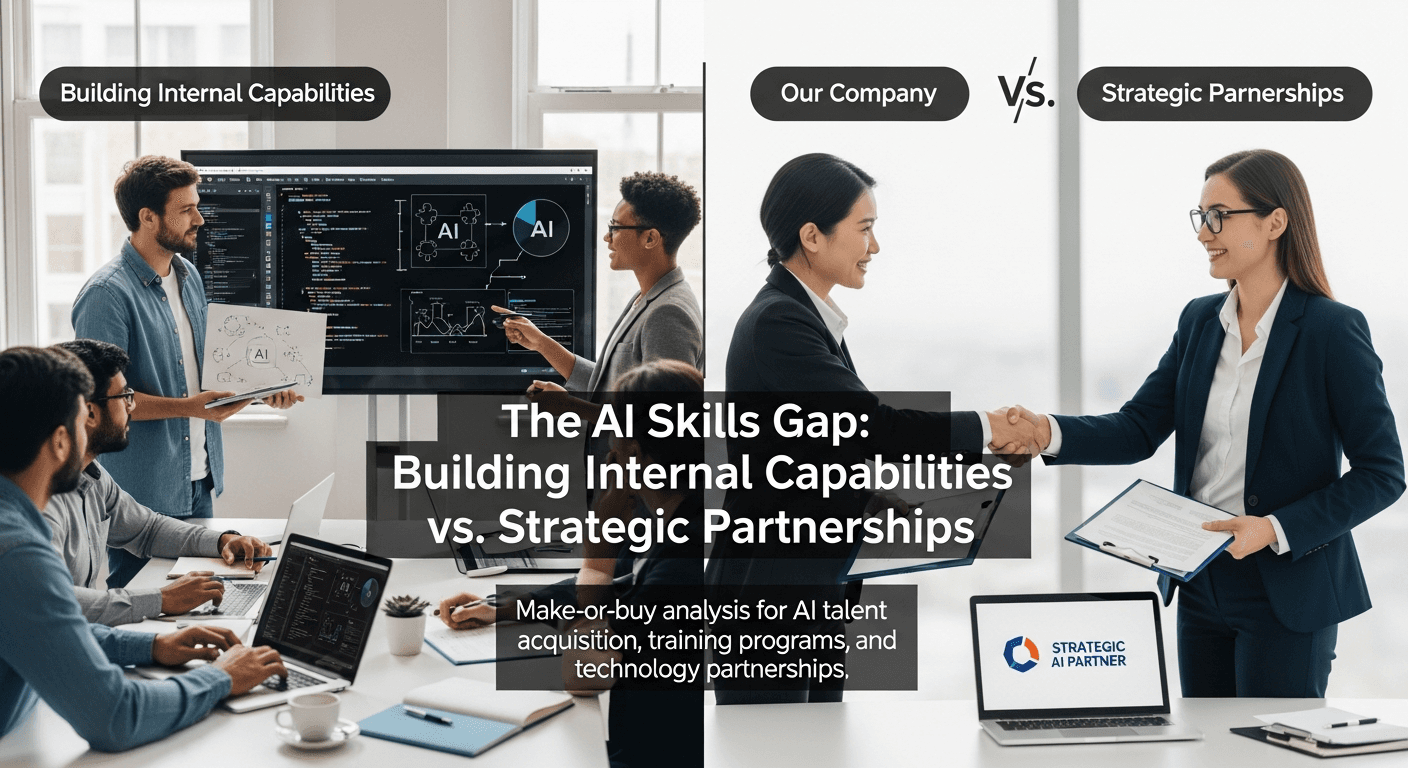

Building Internal Capabilities: Talent and Training Strategies

Internal development invests in upskilling existing staff, creating AI-literate teams through customized programs that blend logistics expertise with technical skills, achieving 80% retention of knowledge. Training initiatives like bootcamps on data analytics and AI governance cost $10K-50K per cohort but deliver 30% productivity uplifts tailored to supply chain nuances. Talent acquisition focuses on hybrid hires—logistics pros with basic AI exposure—fostering a culture of continuous learning via platforms like Coursera for Logistics.

This approach builds proprietary capabilities, reducing vendor lock-in and aligning AI with business strategy over time. Challenges like trainer scarcity are mitigated by phased rollouts, ensuring 50% workforce coverage within a year.

Effective Internal Training Programs

- Foundational Courses: Data literacy workshops for 70% of operations staff, covering AI basics and tools like Python for forecasting.

- Advanced Certifications: Specialized tracks in AI system management, integrating simulations for real-world logistics scenarios.

- Mentorship Ecosystems: Pairing veterans with AI specialists to accelerate on-the-job learning, boosting proficiency by 40%.

- Measurement and Iteration: KPIs like skill assessments track progress, refining programs for 25% annual improvements.

These programs embed AI as a core competency.

Strategic Partnerships: Leveraging External Expertise

Partnerships with AI vendors or consultancies provide instant access to talent and technology, bypassing the 18-month internal build for plug-and-play solutions that cut implementation time by 60%. Collaborations like those with IBM or Accenture offer co-developed platforms for logistics AI, sharing costs and risks while accessing global expert pools. Technology alliances focus on SaaS models for predictive tools, enabling seamless integration without in-house coding expertise.

This path excels in speed and innovation, with firms gaining 35% faster AI adoption through shared best practices. Drawbacks like integration costs are offset by SLAs ensuring alignment with logistics KPIs.

Types of Strategic Partnerships

- Technology Providers: Alliances with AWS or Google Cloud for AI infrastructure, providing scalable compute for demand forecasting.

- Talent Consultancies: Firms like Deloitte for interim AI teams, handling complex projects like blockchain integration.

- Joint Ventures: Co-innovation with startups for custom agents, blending external tech with internal domain knowledge.

- Ecosystem Networks: Participation in AI consortia for shared R&D, reducing individual R&D spends by 50%.

These enhance capabilities without full ownership burdens.

Hybrid Approaches: Combining Make and Buy for Optimal Results

Hybrid models integrate internal training with targeted partnerships, where firms build core skills while outsourcing advanced tech, achieving 45% cost efficiencies and 90% competency coverage. For instance, upskill staff on oversight while partnering for model development, ensuring balanced control and speed. This mitigates risks like skill obsolescence by combining internal loyalty with external innovation.

Logistics leaders adopt hybrids for 70% of AI initiatives, blending academy programs with vendor pilots for iterative growth. Success hinges on clear contracts defining knowledge transfer to sustain internal gains.

Implementing Hybrid Strategies

Phased onboarding uses partnerships for prototypes, transitioning to internal teams post-training. Governance boards oversee alignments, measuring blended ROI through joint KPIs. Resource allocation favors 60% internal for sustainability, 40% external for acceleration. Regular audits ensure seamless handoffs, maximizing hybrid value.

Roadmap: Conducting Your Make-or-Buy Analysis

Phase 1 (Months 1-2): Assess gap via audits, scoring needs against make/buy criteria like cost-benefit matrices. Phase 2 (Months 3-4): Evaluate options—pilot internal training and scout partners—benchmarking timelines and ROIs. Phase 3 (Months 5-8): Implement chosen paths, monitoring with dashboards for adjustments.

Ongoing: Annual reviews adapt to AI trends, with 10-15% budget for hybrids yielding 4x returns. Engage stakeholders early for buy-in, targeting 80% gap closure. Document decisions for scalability.

ROI and Case Studies: Proven Gap-Closing Successes

Make-or-buy strategies deliver 250-400% ROI through 30% faster AI deployment and 20% talent cost reductions. Maersk's hybrid model built internal AI hubs while partnering with Microsoft, slashing forecasting errors by 25%. UPS invested in training alongside Google collaborations, achieving 35% efficiency gains and closing 60% of their skills gap.

These examples validate balanced approaches for logistics excellence.

Explore More on Debales.ai

- Critical Capabilities: The Talent Strategy for AI-Driven Logistics Organizations

- The AI-Human Partnership: Redefining Roles in Modern Logistics Operations

- Managing Change and Overcoming Resistance to AI Adoption in Companies

- Human Side of Supply Chain Automation

- AI Ethics in Logistics: Responsible Automation and Human-AI Collaboration 2025

Bridge Your AI Skills Gap Strategically

Overcome the AI talent challenge with expert make-or-buy guidance. Partner with Debales.ai for a personalized skills assessment and partnership roadmap.

Book an AI Talent Strategy Session

Conclusion: Strategic Choices to Close the Gap

A rigorous make-or-buy analysis for AI talent, training, and partnerships empowers logistics organizations to bridge the skills gap, blending internal builds with external alliances for resilient, innovative operations. This balanced strategy not only addresses immediate needs but secures long-term AI leadership. Act now to transform your workforce