Can AI Really Make a Supply Chain More Resilient and Agile? How?

Friday, 3 Oct 2025

|

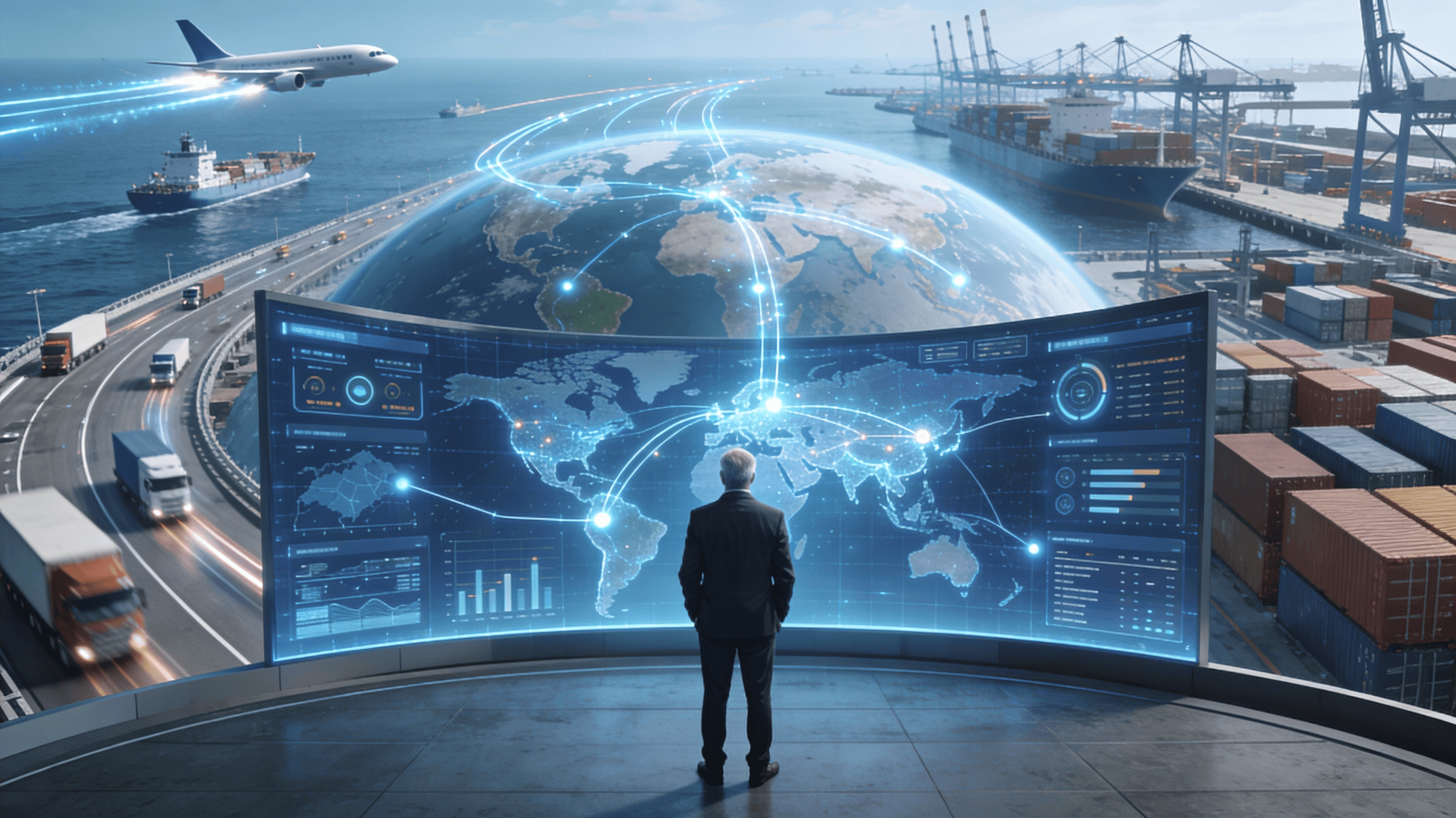

The global logistics landscape is constantly shifting, with supply chains under pressure from increasing customer expectations, unforeseen disruptions, and evolving market conditions. As a CEO, CXO, or COO, navigating these challenges requires a strategic approach that embraces both innovation and efficiency. Enter Artificial Intelligence (AI)—a transformative technology that promises to enhance the resilience and agility of supply chains in ways that were previously unimaginable.

But can AI really make a supply chain more resilient and agile? The answer is a resounding yes. Here’s how AI is reshaping the logistics world and providing businesses with a robust foundation to handle both the expected and the unexpected.

The Case for Resilience: How AI Strengthens Supply Chains

Resilience in a supply chain means the ability to adapt to disruptions—whether it's due to weather, political events, or unexpected spikes in demand. In today’s volatile world, the traditional supply chain model simply doesn’t cut it anymore. AI, however, can enable businesses to recover from setbacks faster and more efficiently. Here's how:

1. Predictive Analytics for Proactive Decision Making

AI-driven predictive analytics can help logistics companies forecast potential disruptions. For example, machine learning models analyze vast amounts of data—from historical trends to real-time information like weather patterns or geopolitical shifts—to predict delays or disruptions.

By anticipating these events, companies can take preventive measures in advance, such as rerouting shipments or adjusting inventory levels, ensuring minimal disruption to the flow of goods.

Real-World Example: Companies like Maersk have integrated AI-driven predictive models to assess weather disruptions, allowing them to adjust routes and avoid delays, significantly improving supply chain resilience.

2. Dynamic Response and Automation

AI allows for automated adjustments in real-time, a crucial factor for agility. For instance, AI-powered systems can instantly reoptimize delivery routes if a supply chain issue arises, saving time and resources. This level of adaptability helps companies remain agile, even in the face of unexpected changes.

In warehouses, AI-driven robots and autonomous vehicles can instantly adapt to fluctuations in demand, optimizing storage space, picking orders, and replenishing stock without the need for manual intervention.

Real-World Example: Amazon has deployed AI robots in its fulfillment centers to optimize the movement of goods in real-time, ensuring continuous operation without human delays.

3. Real-Time Supply Chain Visibility

AI tools like Digital Twins offer a mirror image of a physical supply chain, allowing logistics managers to monitor every stage of the process in real-time. This enhanced visibility helps in identifying bottlenecks or risks early, enabling businesses to take immediate action before small issues escalate.

For example, an AI system might detect that a shipment is delayed at a port due to a local strike. It can then alert the team, suggest rerouting options, and even automatically trigger actions like contacting carriers or notifying customers.

Real-World Example: DHL’s AI-powered supply chain visibility platform integrates data from all supply chain touchpoints, helping businesses manage real-time changes and avoid costly disruptions.

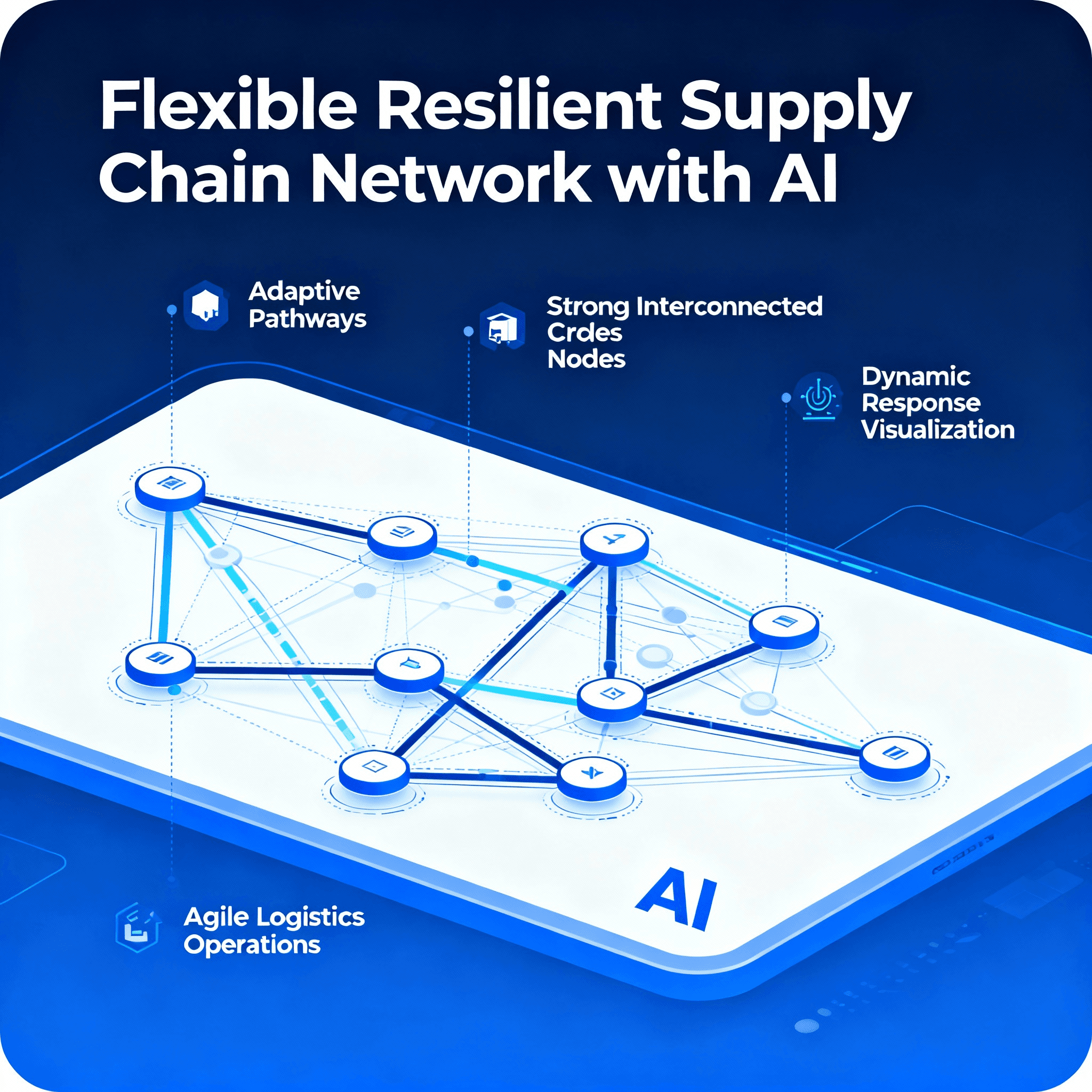

How AI Promotes Agility in Supply Chains

Agility in supply chains is the ability to rapidly adjust to market demands and shifts. AI fosters this flexibility, allowing logistics operations to scale up or down without compromising efficiency. Let’s look at the key ways AI contributes to a more agile supply chain:

1. Demand Forecasting and Inventory Management

AI enhances demand forecasting by analyzing a range of variables, from customer preferences to market trends. AI can predict shifts in demand with incredible accuracy, allowing logistics companies to adjust inventory levels or production schedules ahead of time.

This helps companies avoid stockouts or overstock situations, improving both customer satisfaction and operational efficiency. AI-driven inventory management can automatically place orders with suppliers based on predicted demand, ensuring that the supply chain remains agile and responsive.

2. Smart Contracting and Procurement

AI can also automate procurement and contract management, allowing businesses to respond quickly to changes in demand. For example, AI can evaluate supplier performance, compare pricing, and automatically suggest or place orders based on real-time requirements, ensuring optimal procurement efficiency.

AI-based systems can also flag potential issues with suppliers—such as missed deliveries or poor-quality goods—allowing businesses to switch suppliers with minimal disruption.

3. Scalability and Efficiency

AI-powered solutions provide scalability by allowing businesses to adjust their operations based on current needs. During periods of high demand (such as seasonal spikes), AI can ramp up operations—optimizing route planning, staffing, and inventory management. During quieter periods, AI can scale down operations and reduce excess costs.

This ability to scale operations efficiently, without the need for constant manual intervention, makes supply chains more adaptable and cost-effective.

The Bottom Line: Is AI the Key to Supply Chain Success?

AI is more than just a buzzword in the logistics industry. It is a transformative force that provides supply chains with the resilience and agility they need to thrive in today’s unpredictable world. From predictive analytics and dynamic response systems to real-time visibility and automated processes, AI empowers companies to not only adapt quickly to disruptions but also remain ahead of the curve.

For CEOs, CXOs, and COOs, investing in AI for your supply chain isn’t just an opportunity—it’s a necessity for future-proofing your operations.

Ready to See How AI Can Transform Your Supply Chain?

AI’s role in logistics is only growing, and now is the time to harness its full potential. Want to explore how Debales AI can help make your supply chain more resilient and agile?

Book a demo and see how our AI-driven solutions can optimize your operations and prepare you for future challenges.

For more insights on how AI is transforming logistics, check out our previously published blogs like How Predictive Analytics Works for Logistics, Driving Smarter Supply Chains and AI-Powered Circular Supply Chains: Sustainability Meets Smart Logistics.