Circular Supply Chain: AI Agents for Reverse Logistics Optimization

Wednesday, 29 Oct 2025

|

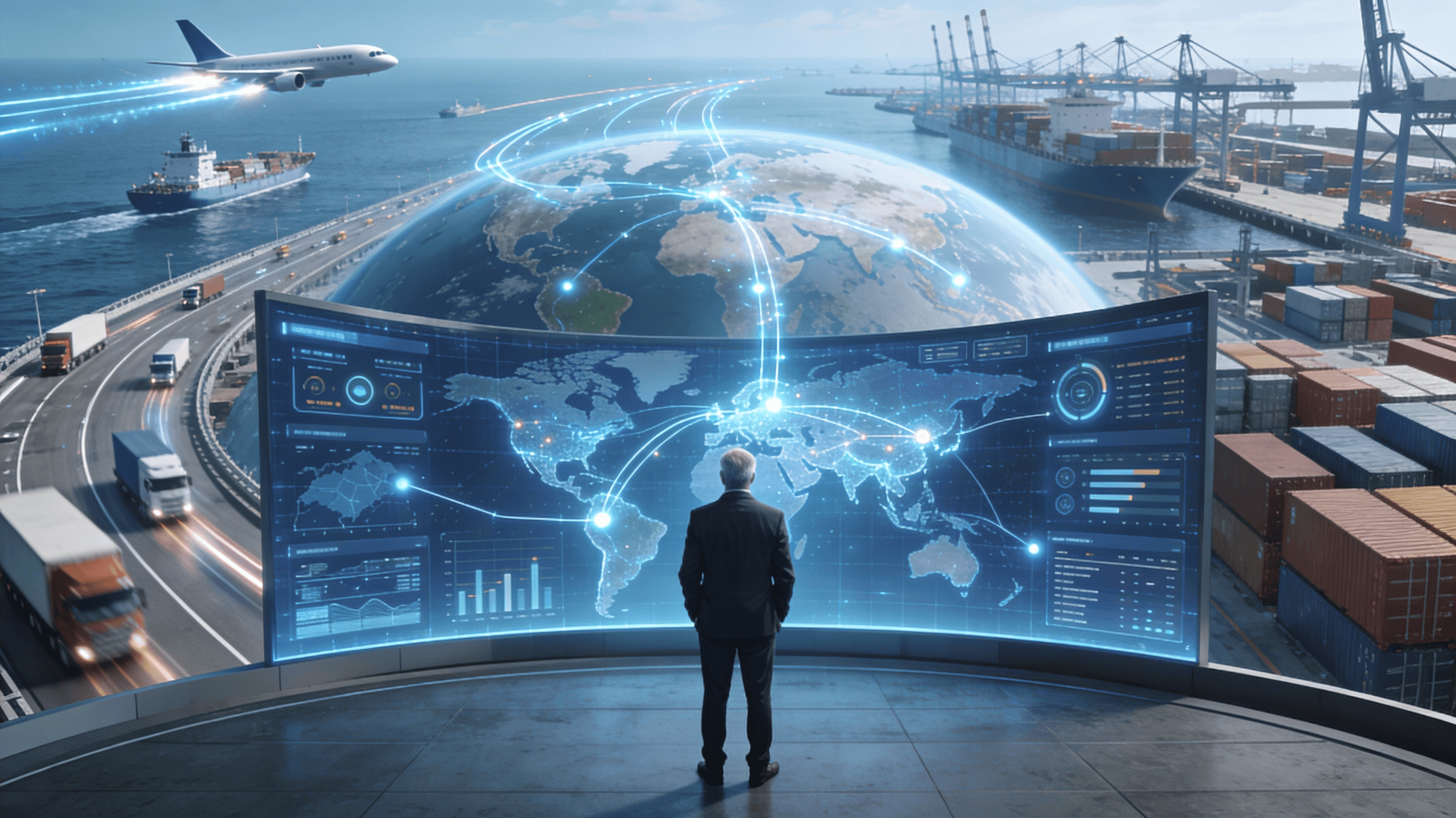

Introduction: Revolutionizing Logistics for a Circular Economy

Reverse logistics processes, including returns, refurbishment, recycling, and disposal, account for 10-15% of e-commerce logistics costs, yet traditional methods lead to 40% waste through inefficient handling and data silos. AI agents optimize these by automating end-to-end product lifecycles, enabling circular models that recover value from returns at 70% rates and reduce landfill contributions by 50% through intelligent sorting and reuse decisions. These systems integrate with WMS and CRM via APIs to predict return patterns, assess refurbishability, and route items to recycling partners seamlessly.

For supply chain executives, sustainability managers, and e-commerce leaders, AI agents turn circularity from an ideal into operational reality, meeting mandates like EU's Waste Framework Directive while boosting profitability through 20-30% material recovery. This guide examines AI's role in circular supply chains, detailing automation strategies, integration tactics, and a deployment framework to enhance reverse logistics efficiency. As circular economy demands grow—with 80% of consumers favoring sustainable brands—AI empowers firms to close loops, minimize waste, and drive long-term value.

Challenges in Traditional Reverse Logistics

Manual returns processing involves disparate systems for inspection, inventory updates, and disposal, resulting in 25% error rates and delays that erode customer trust. Refurbishment decisions rely on subjective assessments, leading to premature scrapping of viable products and lost revenue from secondary markets. Recycling streams suffer from inconsistent sorting, with only 30% of plastics effectively recycled due to contamination from poor lifecycle tracking.

Global operations amplify issues, as cross-border returns face regulatory variances and high transport costs, inflating disposal expenses by 35%. Data fragmentation prevents holistic lifecycle views, hindering circular goals like extended producer responsibility. These hurdles not only increase environmental impact but also strain resources, with returns costing firms $550B annually worldwide.

AI Agents: Intelligent Orchestrators of Circular Flows

AI agents automate reverse logistics by using computer vision and ML to inspect returns upon arrival, classifying items for refurbishment, resale, or recycling with 95% accuracy. Predictive analytics forecast return volumes based on sales data and customer behavior, pre-allocating resources to avoid bottlenecks. Blockchain integration ensures traceability from cradle to grave, verifying circular compliance for audits.

Multi-agent collaboration allows specialization: one agent handles returns triage, another optimizes refurbishment workflows, and a third manages recycling partnerships. Real-time dashboards provide lifecycle insights, enabling dynamic decisions like rerouting products to regional recyclers to cut emissions. This agentic approach transforms reverse processes into value streams, recovering 40% more assets than manual methods.

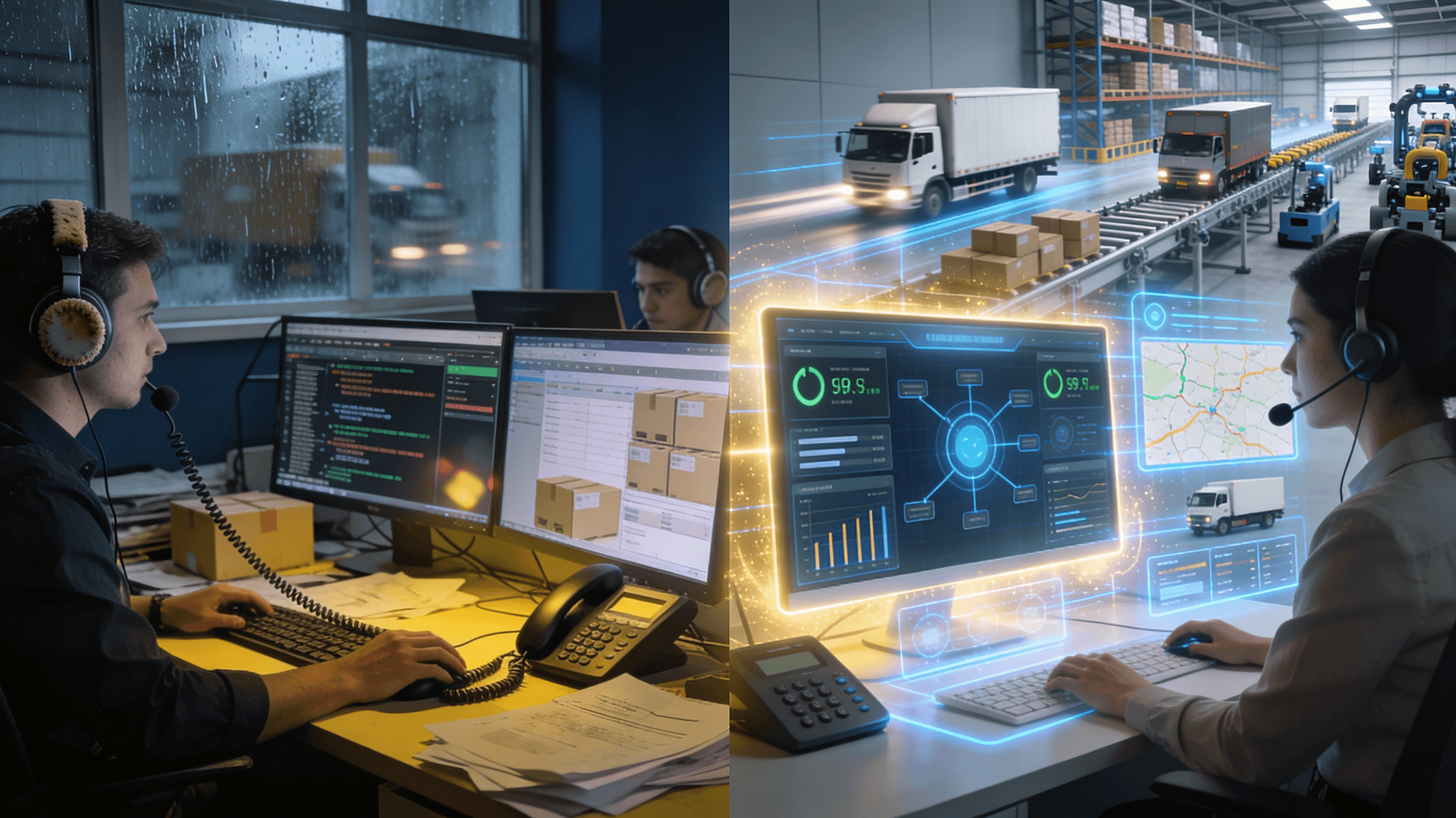

Automation of Returns Processing

AI agents trigger upon return initiation via customer portals, auto-generating labels and scheduling pickups to reduce handling time by 60%. NLP parses return reasons from forms or emails, categorizing for root-cause analysis to prevent future occurrences. Upon receipt, agents orchestrate unboxing and initial scans, flagging high-value items for priority.

Integration with IoT tags tracks items through depots, minimizing losses and ensuring 98% recovery rates. Automated refunds process post-inspection, linking to financial systems for instant payouts. This streamlines operations, cutting return costs per item by 25%.

Refurbishment and Resale Optimization

Computer vision agents evaluate product condition, scoring refurbishability based on wear metrics to decide repair paths. Workflow automation assigns tasks to technicians via AR guides, speeding refurbishment by 50%. Post-refurb, agents price for resale on secondary channels like marketplaces, maximizing recovery value.

Predictive maintenance models extend product lifespans, suggesting upgrades during refurb to enhance circularity. Data from past cycles trains agents to refine processes, achieving 30% higher resale rates. This turns refurbishment into a profit center, contributing 15% to revenue.

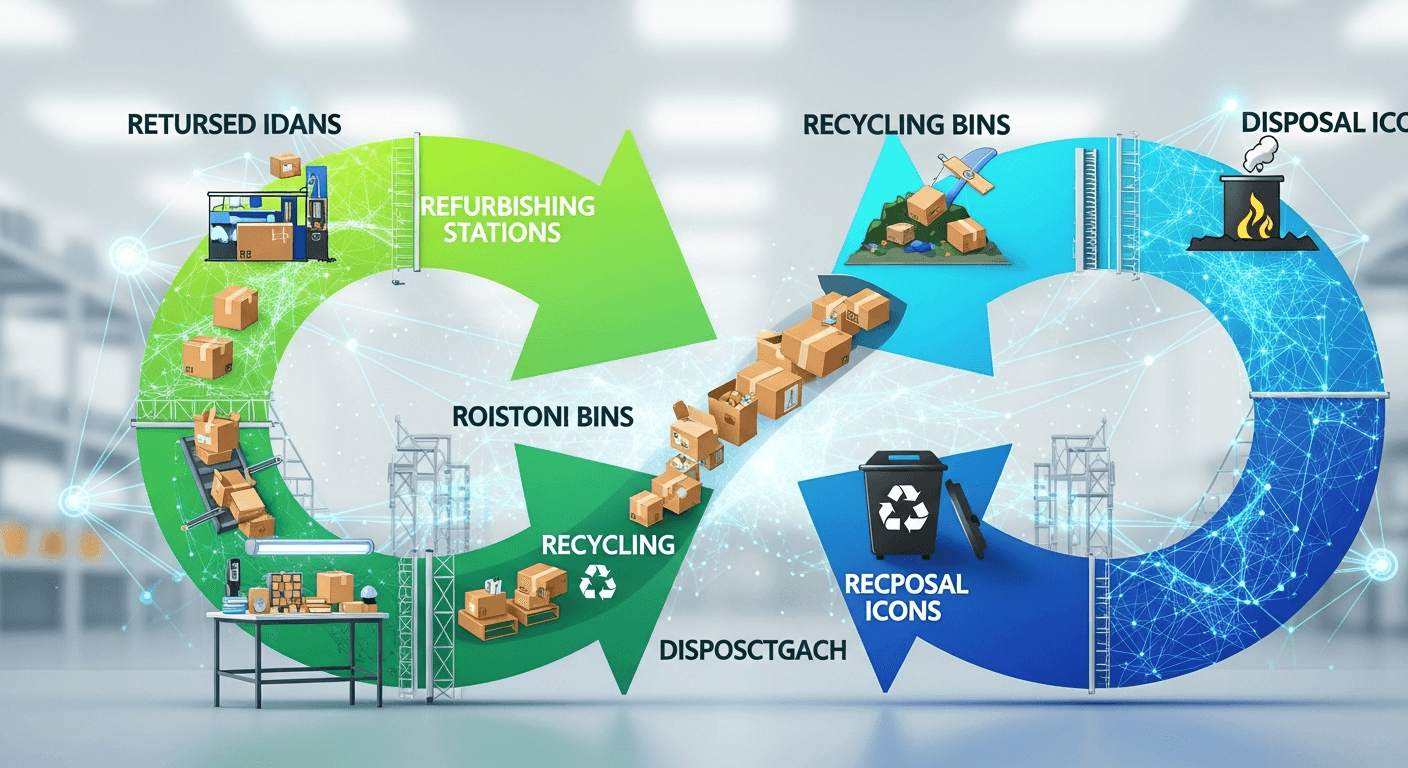

Recycling and Disposal Management

AI sorts recyclables using spectral imaging to identify materials, routing to specialized facilities for 80% purity. Lifecycle assessment agents calculate end-of-life impacts, prioritizing recycling over downcycling where viable. Partnerships with recyclers are automated via smart contracts, ensuring compliant disposal and credit claims.

For non-recyclables, agents recommend sustainable disposal like energy recovery, minimizing Scope 3 emissions. Analytics track recycling yields, optimizing supplier selections for circular materials. These processes reduce waste by 45%, aligning with zero-landfill goals.

Integration Strategies: Building a Unified Circular Ecosystem

Connect AI agents to existing PLM and SCM systems via middleware like MuleSoft, enabling bidirectional data flows for lifecycle updates. Cloud platforms host agents for scalability, processing high-return volumes during peaks like holidays. API gateways secure integrations with e-commerce backends, pulling order data for return predictions.

Hybrid models blend on-prem for sensitive data with cloud for analytics, ensuring GDPR compliance in global chains. Low-code interfaces allow operations teams to customize agent rules, such as refurb thresholds. Testing in digital twins simulates circular scenarios, validating efficiency before rollout.

Data and Technology Enablers

Federated learning aggregates insights across partners without sharing proprietary data, enhancing recycling network intelligence. IoT and RFID provide granular tracking, feeding agents with real-time condition data. Edge computing enables on-site decisions, like instant sorting in return centers.

Sustainability KPIs embed in agent objectives, balancing cost with environmental impact. Vendor ecosystems expand capabilities, integrating with recycling tech providers.

Roadmap: Implementing AI for Circular Supply Chains

Phase 1 (Months 1-2): Audit current reverse processes and pilot returns automation on one category, integrating basic AI triage. Phase 2 (Months 3-5): Expand to refurbishment and recycling, training agents on historical data for 20% efficiency gains. Phase 3 (Months 6-9): Full lifecycle orchestration, scaling globally with partner integrations.

Ongoing: Monitor via analytics, iterating based on recovery rates and emission metrics. Allocate 10% of supply chain budget initially, targeting 3x ROI within a year. Address challenges like data quality through cleansing protocols.

ROI and Case Studies: Circular Success with AI

AI circular agents deliver 200-400% ROI by recovering $100K+ per 1M units through optimized returns and resale. IKEA's AI-enhanced reverse logistics boosted refurb rates by 35%, saving €10M annually. Patagonia uses agents for lifecycle tracking, achieving 50% recycled material use and 20% cost reductions.

These implementations show how automation closes loops, enhancing brand loyalty and regulatory standing.

Explore More on Debales.ai

- How AI Assists in Managing Reverse Logistics and Customer Returns

- AI-Powered Circular Supply Chains: Sustainability Meets Smart Logistics

- In What Ways Does AI Improve Sustainability in Logistics E.g. Reducing Carbon Footprint

- From Silos to Synergy: How AI Agents Unify Fragmented Supply Chain Data

- Multi-Agent Orchestration: Autonomous Collaboration in Supply Chains

Optimize Your Circular Supply Chain with AI

Embrace circularity with AI agents tailored for reverse logistics. Contact Debales.ai for a lifecycle assessment and implementation strategy.

Conclusion: Closing the Loop with Intelligent Automation

AI agents revolutionize circular supply chain management by automating returns, refurbishment, recycling, and disposal, fostering sustainable product lifecycles and economic gains. This optimization not only meets circular economy demands but enhances efficiency and resilience in logistics. Implement AI today to lead in sustainable innovation.