How AI Enhances Supply Chain Visibility from End to End?

Tuesday, 30 Sep 2025

|

How AI Enhances Supply Chain Visibility from End to End

Imagine knowing exactly where every shipment is, predicting delays before they occur, and having complete transparency from raw material sourcing through final delivery—not through manual tracking and phone calls, but through intelligent systems that monitor, analyze, and alert automatically.

This isn't futuristic thinking—it's the reality AI-powered supply chain visibility delivers today. Yet most organizations still operate with fragmented visibility: inventory systems don't talk to transportation platforms, suppliers provide sporadic updates through email, and decision-makers rely on outdated dashboards showing where things were, not where they are.

The cost of this opacity is staggering: 69% of businesses lack complete visibility into their supply chains, resulting in billions lost annually to stockouts, excess inventory, missed deliveries, and inefficient responses to disruptions. Organizations implementing AI-powered end-to-end visibility report 30% faster response times to disruptions, 25% reduction in logistics costs, and 20-35% improvement in on-time delivery performance.

For logistics leaders navigating increasingly complex global supply chains, understanding how AI transforms visibility from fragmented glimpses into comprehensive intelligence isn't just operational improvement—it's competitive survival.

Wondering what "true" end-to-end visibility actually means? It's seeing every product, shipment, and transaction flow through your supply chain in real time, with AI predicting what comes next.

The Visibility Gap: Why Traditional Approaches Fall Short

Traditional supply chain visibility relies on disconnected systems, manual data entry, and periodic status updates that create incomplete pictures:

Fragmented Data Sources: ERP, TMS, WMS, supplier portals, and carrier systems operate in silos without integration

Delayed Information: Status updates lag reality by hours or days, making proactive decision-making impossible

Limited Tracking Points: Visibility exists only at specific checkpoints (shipment dispatch, warehouse arrival) with blind spots between

Manual Reconciliation: Teams waste hours consolidating data from multiple sources into coherent status reports

No Predictive Capability: Systems show what happened or what's happening, never what will happen

The business impact? According to Gartner, supply chain leaders spend 30% of their time manually tracking and reconciling shipment information—time that could be spent on strategic initiatives.

For context on how AI fundamentally differs from traditional systems, explore A Simple Analogy for How AI Optimizes a Supply Chain.

How AI Delivers End-to-End Supply Chain Visibility

1. Unified Data Integration Across All Systems

AI-powered platforms automatically aggregate data from disparate sources—ERP, TMS, WMS, IoT sensors, carrier systems, supplier portals, and external data feeds—creating unified real-time visibility.

Intelligent data processing:

- Automated extraction: AI identifies and pulls relevant data elements from diverse systems (purchase orders, inventory levels, shipment milestones, quality checks)

- Data normalization: Converts information from different formats and standards into consistent, comparable formats

- Continuous synchronization: Updates visibility in real time as data changes across any connected system

- Gap filling: Uses predictive algorithms to estimate missing data points when direct feeds are unavailable

Business outcome: Instead of checking five different systems and making phone calls to track a shipment, a single dashboard shows complete status across the entire journey.

Learn about the data requirements enabling this integration in What Kind of Data is Needed to Train an Effective AI Model for Supply Chain Optimization?.

2. Real-Time Tracking with IoT and AI

The combination of IoT sensors and AI analytics provides continuous, granular visibility into product location, condition, and estimated arrival times.

IoT tracking capabilities:

- GPS and RFID: Real-time location tracking for shipments in transit

- Temperature and humidity sensors: Monitoring conditions for sensitive products (pharmaceuticals, food)

- Shock and tilt sensors: Detecting improper handling or potential damage

- Asset tracking: Visibility into trailers, containers, and reusable packaging

AI enhancement layer:

- Predictive ETAs: AI analyzes current progress, traffic, weather, and historical patterns to calculate accurate arrival times

- Anomaly detection: Flags unusual patterns (unexpected stops, route deviations, environmental changes) immediately

- Automated alerts: Proactive notifications when exceptions require attention

Example: Maersk uses AI-powered IoT tracking across its container fleet, providing customers with real-time location updates and precise ETA predictions, reducing customer inquiries by 40%.

Discover how these tracking capabilities extend to warehouse operations in How Computer Vision Technology Helps in Logistics Operations.

3. Predictive Analytics for Proactive Decision-Making

AI doesn't just show where things are—it predicts where they'll be and what problems might occur.

Predictive capabilities:

- Delay forecasting: AI predicts potential delays 48-72 hours before they occur based on weather patterns, port congestion, traffic trends, and supplier performance

- Disruption detection: Machine learning identifies supply chain vulnerabilities before they escalate into crises

- Demand prediction: Forecasts downstream demand enabling proactive inventory positioning

- Alternative route recommendations: Suggests optimal rerouting when disruptions are predicted

Business impact: FedEx's AI-powered control tower predicts delays before they occur, automatically rerouting shipments and achieving 20% improvement in on-time delivery.

Learn more about predictive capabilities in How Predictive Analytics Works for Logistics.

4. Digital Twins for Simulation and Optimization

AI-powered digital twins create virtual replicas of entire supply chains, enabling "what-if" scenario testing and continuous optimization.

Digital twin capabilities:

- Virtual supply chain models: Real-time digital representations mirroring physical operations

- Disruption simulation: Testing responses to potential problems (supplier failures, natural disasters, demand spikes) before they occur

- Optimization testing: Evaluating alternative strategies (new suppliers, route changes, inventory policies) without operational risk

- Continuous learning: Models improve as real-world data refines predictions

Strategic advantage: Organizations using digital twins report 15-30% improvement in decision quality and 20-25% faster response to disruptions.

Explore digital twin technology in depth at What is a Digital Twin and How is it Used in Logistics AI?.

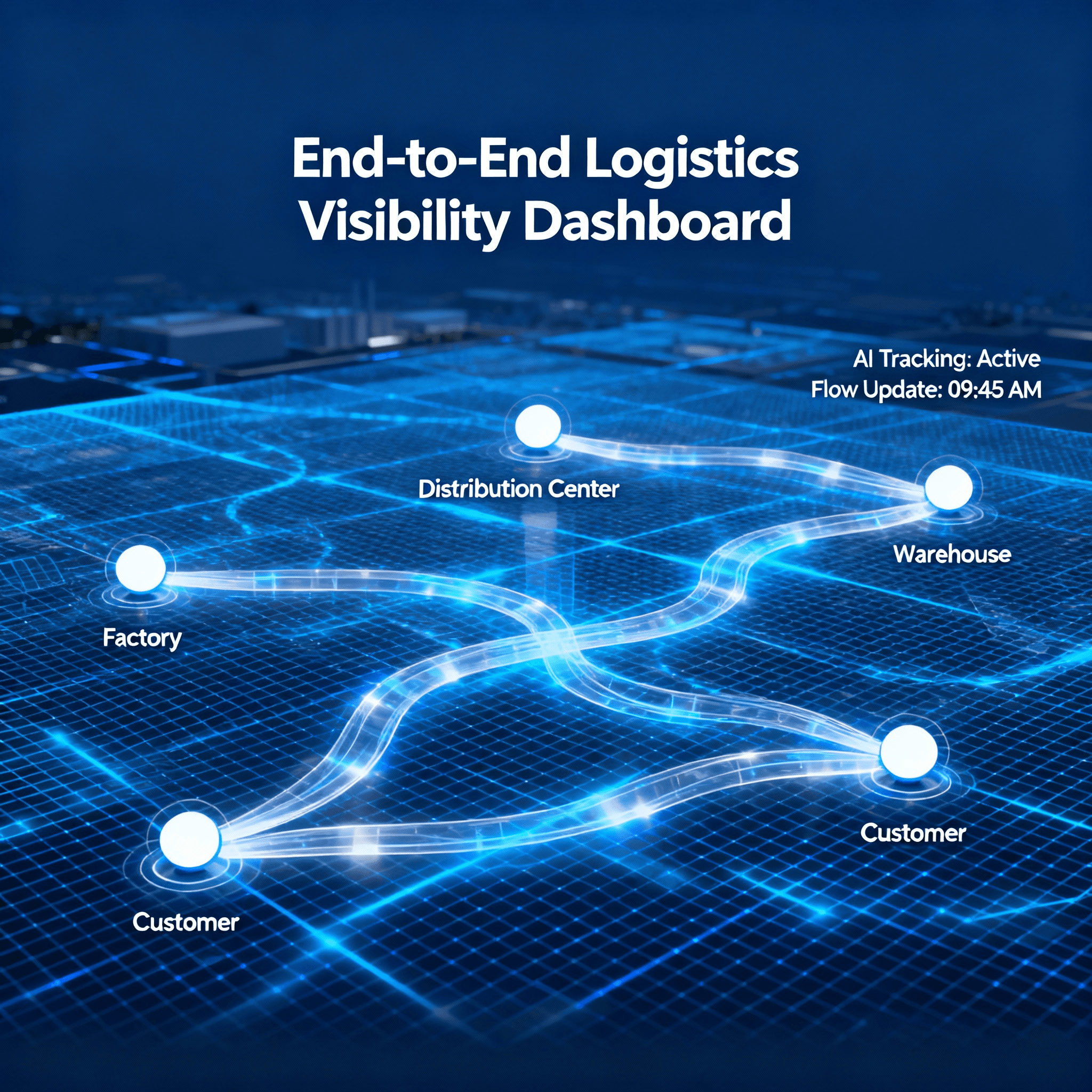

5. Intelligent Control Towers Orchestrating Across Networks

AI-powered control towers serve as command centers providing unified visibility and automated orchestration across entire supply chain networks.

Control tower functions:

- Centralized visibility: Single dashboard showing status across all suppliers, manufacturing sites, warehouses, transportation modes, and delivery points

- Exception management: Automated flagging and prioritization of issues requiring attention

- Collaborative workflows: Connecting internal teams, suppliers, carriers, and customers with shared visibility and communication tools

- Performance analytics: Real-time KPIs showing on-time delivery rates, inventory levels, cost metrics, and service quality

Operational impact: Companies using AI control towers report 30-50% reduction in time spent on manual tracking and coordination activities.

Understand control tower capabilities in What is an AI-Powered Control Tower in Logistics?.

6. Automated Customer Communication and Transparency

AI enables proactive, transparent communication with customers through automated tracking updates and intelligent chatbots.

Customer-facing visibility:

- Real-time tracking portals: Self-service access to shipment status and estimated delivery times

- Proactive notifications: Automated alerts for shipment progress, delays, or delivery windows

- AI chatbots: 24/7 answering of tracking inquiries in multiple languages

- Transparent exception handling: Automatic customer notification and resolution updates when issues occur

Customer experience impact: Organizations providing AI-powered tracking transparency report 40% reduction in "where is my order" inquiries and 25% improvement in customer satisfaction scores.

Learn about communication automation in How Natural Language Processing (NLP) Applies to the Logistics Industry.

Real-World AI Visibility Success Stories

Walmart: End-to-End Supply Network Visibility

Walmart implemented comprehensive AI-powered visibility across its global supply chain:

Solution: Integrated platform connecting 100,000+ suppliers, 150+ distribution centers, and 11,000+ stores

AI capabilities: Real-time inventory tracking, predictive demand forecasting, automated replenishment

Results:

- 30% improvement in inventory accuracy

- $1+ billion in supply chain cost savings annually

- Significant reduction in stockouts during peak demand

DHL: AI-Powered Logistics Visibility Platform

DHL deployed AI-driven visibility solutions across global logistics operations:

Technology: IoT sensors, predictive analytics, and control tower dashboards

Features: Real-time shipment tracking, delay prediction, automated exception management

Impact:

- 25% improvement in on-time delivery performance

- 20% reduction in customer service inquiries

- Enhanced ability to proactively manage disruptions

Discover related route optimization examples in Real-World Examples of AI Route Optimization.

Measurable Business Benefits

Organizations implementing AI-powered end-to-end visibility report consistent improvements:

Operational Efficiency

- 30% faster response times to supply chain disruptions

- 40-60% reduction in manual tracking time freeing staff for strategic work

- 25% decrease in expedited shipping costs through better planning

- 20-30% improvement in inventory accuracy

Cost Reduction

- 15-25% lower logistics costs through optimized operations

- 20-35% reduction in working capital tied up in inventory

- 30% decrease in stockout-related lost sales

- Significant savings from avoided disruption costs

Customer Experience

- 20-35% improvement in on-time delivery

- 40% reduction in customer service inquiries

- 25-40% increase in customer satisfaction scores

- Higher customer retention through delivery reliability

Risk Management

- 48-72 hour advance warning of potential disruptions

- Improved compliance with regulatory tracking requirements

- Enhanced supplier performance visibility

- Better contingency planning through scenario simulation

Technologies Powering AI Visibility

IoT and Sensor Networks

Physical tracking infrastructure providing real-time data:

- GPS tracking devices on vehicles and containers

- RFID tags for product-level identification

- Environmental sensors monitoring temperature, humidity, shock

- Smart pallets and packaging with embedded sensors

Machine Learning and Predictive Analytics

AI algorithms processing data to generate insights:

- Anomaly detection identifying unusual patterns

- Predictive models forecasting delays and disruptions

- Demand forecasting driving proactive positioning

- Pattern recognition revealing optimization opportunities

Learn about these algorithms in Most Common AI Algorithms Used for Route Planning and Demand Forecasting.

Cloud Platforms and API Integration

Infrastructure connecting diverse systems:

- Cloud computing enabling scalable data processing

- API integrations connecting ERP, TMS, WMS, and external systems

- Data lakes storing historical information for model training

- Real-time dashboards visualizing complex supply chain networks

How debales.ai Delivers End-to-End Visibility Intelligence

At debales.ai, our AI platform provides comprehensive supply chain visibility capabilities:

Unified Data Integration: Automatic aggregation from ERP, TMS, WMS, IoT devices, and carrier systems into single source of truth

Real-Time Tracking: Continuous monitoring with AI-enhanced ETA predictions and exception detection

Predictive Analytics: Delay forecasting, disruption alerts, and demand prediction enabling proactive decisions

Control Tower Dashboard: Centralized visibility across entire supply chain network with actionable insights

Automated Communication: AI-powered customer notifications, chatbots, and exception handling

Seamless Integration: Connects with existing systems without requiring complete technology replacement

Explainable AI: Transparent reasoning showing why alerts are generated and what drives predictions

Our approach combines visibility intelligence with the automation capabilities detailed in In What Ways Does AI Automate and Improve Inventory Management?.

Implementation Roadmap

Successful AI visibility implementations follow structured approaches:

Phase 1: Assessment

- Map current visibility gaps and pain points

- Identify critical tracking points and data sources

- Establish baseline metrics (tracking time, exception rates, costs)

Phase 2: Foundation Building

- Integrate core systems (ERP, TMS, WMS)

- Deploy IoT tracking infrastructure where needed

- Establish data quality processes

Phase 3: AI Deployment

- Implement predictive analytics and anomaly detection

- Launch control tower dashboards

- Enable automated alerting and exception management

Phase 4: Continuous Optimization

- Expand visibility across additional suppliers and partners

- Refine AI models based on performance

- Scale successful implementations globally

The Strategic Imperative

In an era of supply chain disruptions, customer expectations for transparency, and competitive pressure on margins, end-to-end visibility isn't optional—it's existential.

Organizations still operating with fragmented, manual visibility face widening disadvantages against competitors achieving 30% faster response times and 25% lower costs through AI-powered transparency.

Ready to transform supply chain opacity into intelligent, end-to-end visibility?

Discover how debales.ai's AI-powered platform delivers real-time tracking, predictive insights, and automated orchestration—turning visibility from operational challenge into strategic advantage.

Book a demo with debales.ai today and experience supply chain transparency reimagined for competitive excellence.