How AI Improves the Accuracy of Demand Forecasting in Logistics?

Saturday, 27 Sep 2025

|

How AI Improves the Accuracy of Demand Forecasting in Logistics

The gap between what customers want and what sits in warehouses costs businesses billions annually. Too much inventory ties up capital and risks obsolescence. Too little creates stockouts, lost sales, and frustrated customers. At the heart of this challenge lies demand forecasting—predicting future customer needs with enough accuracy to optimize inventory levels.

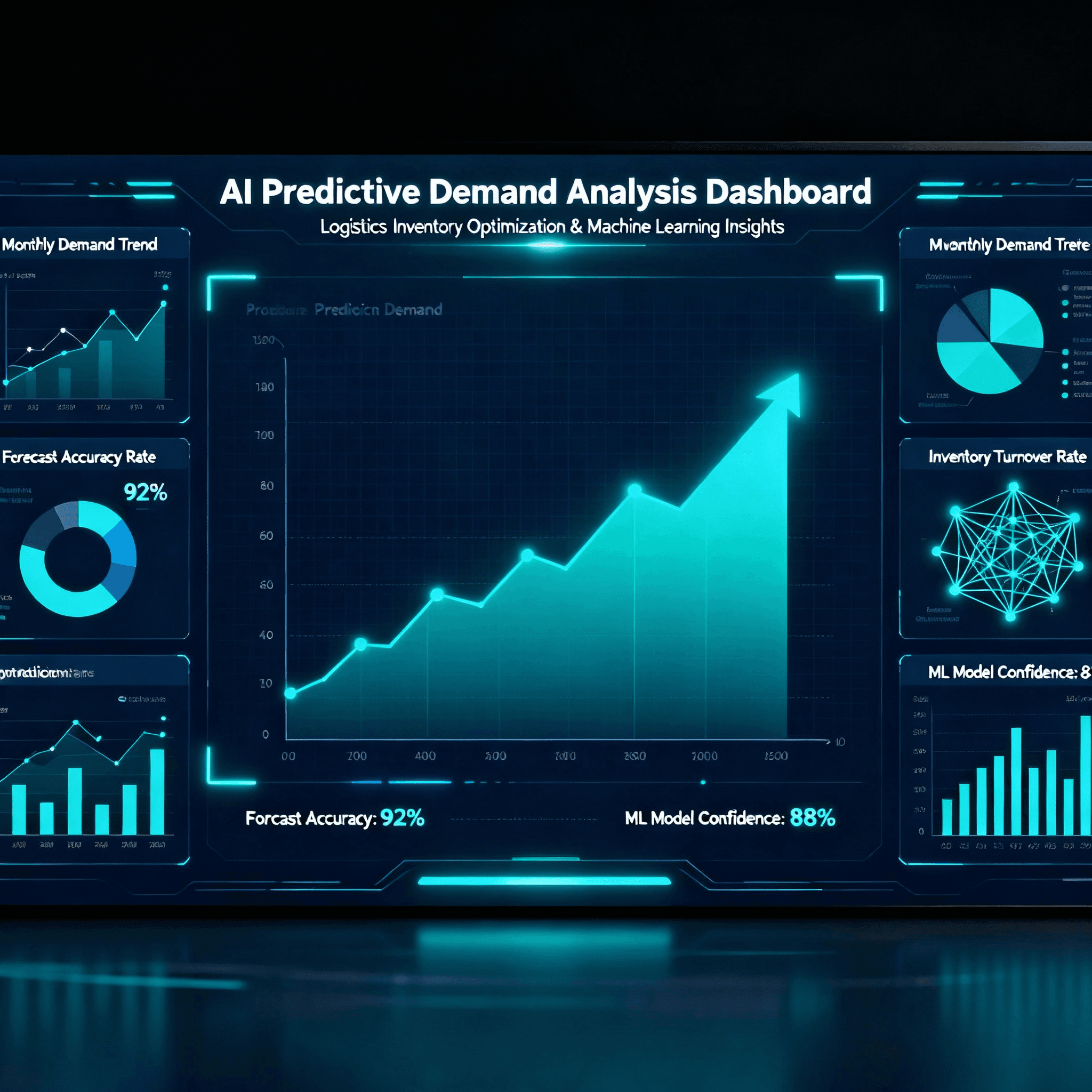

Traditional forecasting methods achieve median accuracy between 70-79%, leaving significant room for costly errors. But AI-powered demand forecasting is changing the game, reducing forecast errors by 20-50% and in some cases achieving accuracy rates up to 95%.

For logistics and supply chain leaders, understanding how AI delivers these improvements isn't just technical curiosity—it's the difference between thriving and merely surviving in increasingly competitive markets.

Wondering what makes AI forecasting so much more accurate? The answer lies in its ability to see patterns humans miss and adapt faster than manual processes ever could.

The Limitations of Traditional Demand Forecasting

Traditional forecasting methods rely primarily on historical sales data processed through statistical techniques like moving averages, exponential smoothing, or simple linear regression.

These approaches struggle because they:

- Assume past patterns will repeat consistently, missing disruptions and trend shifts

- Handle only limited variables (typically just historical sales and basic seasonality)

- Require manual updates and adjustments, creating delays in responsiveness

- Cannot detect subtle correlations across thousands of data points

- Treat all products identically rather than optimizing at SKU level

The result? Error rates as high as 50%, especially when market conditions shift unexpectedly. In logistics, this translates to overstocked warehouses, emergency shipments, lost sales, and eroded margins.

For context on how AI differs fundamentally from traditional methods, explore What's the Difference Between AI, Machine Learning, and Automation in a Warehouse Context?.

How AI Transforms Demand Forecasting Accuracy

1. Processing Vastly More Data Sources

While traditional methods analyze historical sales, AI ingests and correlates hundreds of variables simultaneously:

Internal data:

- Historical sales patterns across multiple timeframes

- SKU-level performance trends

- Warehouse inventory levels and turnover rates

- Promotional campaign histories and outcomes

External data:

- Weather patterns affecting demand

- Economic indicators and market trends

- Social media sentiment and trending topics

- Competitor pricing and promotional activities

- Industry news and supply chain disruptions

This comprehensive data integration enables AI to understand demand drivers that traditional models completely miss. For insights into the data requirements, read What Kind of Data is Needed to Train an Effective AI Model for Supply Chain Optimization?.

2. Detecting Non-Linear Patterns and Complex Relationships

Traditional statistical models assume linear relationships—if sales increased 5% last January, they'll increase 5% this January. Real-world demand rarely works this way.

AI algorithms like neural networks, gradient boosting machines, and ensemble methods excel at detecting non-linear patterns and complex interactions across variables. They recognize that:

- Weekend demand patterns differ from weekday patterns in non-obvious ways

- Temperature doesn't impact demand linearly—there are thresholds where behavior changes dramatically

- Promotional effectiveness varies by product category, season, and competitive activity

3. Real-Time Continuous Learning

Traditional forecasts are static—updated weekly, monthly, or quarterly through manual processes. By the time planners act on forecasts, conditions have often changed.

AI systems continuously learn and adapt:

- Ingest new data hourly or even in real-time

- Automatically recalibrate predictions as conditions shift

- Detect emerging trends before they become obvious

- Flag anomalies and outliers that require attention

This dynamic updating means forecasts remain current, enabling agile responses to demand fluctuations. Learn more about real-time intelligence in What is an AI-Powered Control Tower in Logistics?.

4. SKU-Level Granularity at Scale

Traditional methods often forecast at aggregate levels (total warehouse demand, category-level demand) because granular SKU-level forecasting becomes computationally overwhelming and time-intensive.

AI handles thousands of SKUs simultaneously, generating individualized forecasts for each product that account for its unique demand drivers, seasonality patterns, and lifecycle stage. This precision enables:

- Targeted inventory optimization per SKU

- Customized reorder points and safety stock levels

- Identification of fast-movers and slow-movers for differentiated strategies

5. Automated Feature Engineering and Model Selection

Expert forecasters spend significant time identifying which variables matter most and selecting appropriate statistical techniques. AI automates this through feature engineering and ensemble methods.

Machine learning systems:

- Test hundreds of potential predictive variables automatically

- Select optimal algorithms for each product or category

- Combine multiple models (ensemble methods) for superior accuracy

- Continuously evaluate and improve model performance

To understand the algorithms powering these capabilities, explore Most Common AI Algorithms Used for Route Planning and Demand Forecasting.

Quantifying the Accuracy Improvement

The improvement AI delivers isn't incremental—it's transformational:

McKinsey Research: AI-driven forecasting reduces errors by 20-50% compared to traditional approaches

Industry Performance:

- Traditional forecasting: 70-79% median accuracy

- AI-powered forecasting: 85-95% accuracy achievable

- Error reduction translates to 20-30% reduction in lost sales and 20-35% reduction in inventory costs

Real-world examples:

- Danone reduced forecast error by 20% and decreased lost sales by 30% after implementing machine learning

- C.H. Robinson achieved automation across the entire freight lifecycle using AI, enhancing efficiency and responsiveness in demand forecasting

- IBM Watson Supply Chain improved inventory visibility and automated replenishment through ML-powered demand prediction

The Business Impact of Improved Forecast Accuracy

Better forecasting accuracy cascades into multiple operational improvements:

Inventory Optimization

- 20-35% reduction in carrying costs through right-sized stock levels

- Reduced stockouts maintaining service levels above 95%

- Lower obsolescence and waste from overproduction

Operational Efficiency

- 30% labor savings as automation replaces manual forecasting tasks

- Faster planning cycles enabling weekly or daily adjustments instead of monthly

- Better resource allocation aligning warehouse and transportation capacity with predicted demand

Financial Performance

- Improved cash flow from reduced working capital tied up in excess inventory

- Higher revenue through better product availability when customers want to buy

- Competitive advantage through superior service levels and responsiveness

These operational improvements connect directly to the broader benefits described in A Simple Analogy for How AI Optimizes a Supply Chain.

How debales.ai Delivers Superior Forecast Accuracy

At debales.ai, our AI-powered logistics platform integrates advanced demand forecasting capabilities designed specifically for logistics operations:

Multi-Model Ensemble Approach: Automatically tests and combines multiple algorithms (ARIMA, Prophet, XGBoost, neural networks) selecting optimal methods for each SKU

Real-Time Data Integration: Connects seamlessly with ERP, WMS, TMS, and external data sources for continuous forecast updates

Intelligent Anomaly Detection: Flags outliers and unusual patterns that might distort predictions, ensuring forecast reliability

Explainable AI: Provides transparency into which factors drive forecasts, building trust and enabling human oversight

Automated Inventory Recommendations: Translates forecasts directly into actionable reorder points, safety stock levels, and purchase suggestions

Our approach combines the predictive power detailed in How Predictive Analytics Works for Logistics with automated decision support.

Implementing AI Demand Forecasting: Best Practices

Successful AI forecasting implementations follow structured approaches:

1. Ensure Data Quality: Clean, normalize, and integrate diverse data sources—garbage in, garbage out applies even to AI

2. Start with High-Value SKUs: Focus initial implementations on products where forecast improvements deliver maximum impact

3. Establish Performance Metrics: Track forecast accuracy, bias, and business outcomes (inventory turns, service levels, costs) to demonstrate ROI

4. Maintain Human Oversight: AI should augment, not replace, human judgment—especially for strategic decisions and exception handling

5. Continuously Refine: Regularly evaluate model performance and retrain with new data as business conditions evolve

The Future: From Forecasting to Autonomous Planning

Next-generation AI systems are evolving beyond forecasting to autonomous planning—where AI not only predicts demand but automatically executes procurement, inventory allocation, and distribution decisions.

This autonomous capability represents the vision described in What is a Digital Twin and How is it Used in Logistics AI?—where virtual models simulate and optimize entire supply chains.

Moving from Reactive to Predictive

The question facing logistics leaders isn't whether to adopt AI-powered forecasting—it's how quickly they can implement it before competitors gain insurmountable advantages.

Organizations still relying on traditional forecasting face widening accuracy gaps, higher costs, and deteriorating service levels compared to AI-enabled peers achieving 20-50% better performance.

Ready to transform demand forecasting from your biggest challenge into your competitive advantage?

Discover how debales.ai's AI-powered platform delivers industry-leading forecast accuracy, reducing errors by up to 50% while automating labor-intensive planning processes.

Book a demo with debales.ai today and experience the difference AI-driven forecasting makes for inventory optimization, service levels, and bottom-line performance.

All blog posts

View All →

Friday, 6 Mar 2026

Agents vs RPA: The Freight Automation Mistake

Autonomous agents outperform RPA by resolving 70%+ exceptions without escalation. Learn the 5-question framework to avoid the wrong freight automation bet.

Friday, 6 Mar 2026

Freight Invoice Errors Cost $200K+: How to Stop Them

Freight invoice errors cost logistics operations $30–300K annually. Discover the 5 root causes, full financial impact, and how automation recovers losses.

Thursday, 5 Mar 2026

Cut Your DSO in Half: AI Cash Flow Acceleration for Logistics

AI accounts receivable automation cuts logistics DSO from 45+ days to under 25 days. See the exact playbook freight brokers and 3PLs use to free $3M+ in working capital.