How Computer Vision Technology Helps in Logistics Operations ?

Wednesday, 24 Sep 2025

|

How Computer Vision Technology Helps in Logistics Operations

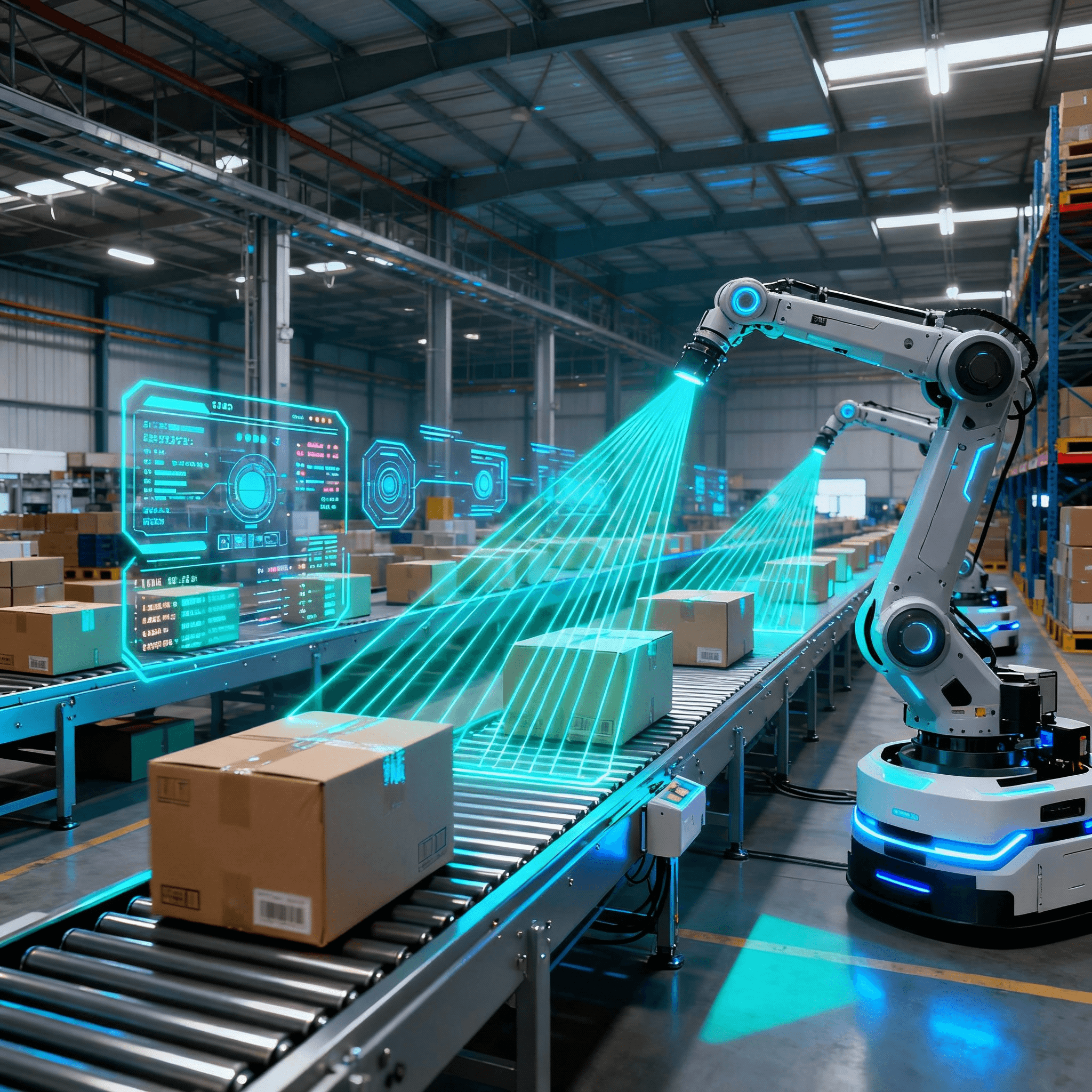

Picture this: a warehouse where every package is tracked automatically, every item is verified without human touch, and potential quality issues are caught before they become costly problems. This isn't science fiction—it's the reality computer vision is creating in logistics operations today.

Computer vision, powered by AI algorithms and high-resolution cameras, enables machines to "see" and interpret visual data, transforming how warehouses and distribution centers operate. For organizations seeking operational excellence, understanding computer vision's role is essential for staying competitive in 2025 and beyond.

Wondering how visual AI translates into bottom-line results? Keep reading to discover the transformative applications reshaping logistics.

What is Computer Vision in Logistics?

Computer vision combines AI, machine learning, and image processing to enable automated systems to analyze visual information from cameras and sensors. In logistics contexts, this means real-time identification, tracking, verification, and quality assessment of goods throughout the supply chain.

Unlike traditional barcode scanning that requires manual intervention, computer vision systems continuously monitor warehouse environments, providing instant insights and enabling autonomous decision-making.

For those new to AI concepts in logistics, explore What Exactly Is AI in Logistics and Supply Chain Management? to understand the broader technology landscape.

Key Applications Transforming Warehouse Operations

Automated Inventory Management

Computer vision eliminates manual stock counts by using cameras strategically placed throughout warehouses to continuously track inventory levels. AI algorithms identify items, read barcodes or labels using optical character recognition (OCR), and automatically update inventory records in real-time.

According to Gartner, by 2027, 50% of companies with warehouse operations will leverage AI-enabled vision systems to replace traditional scanning-based cycle-counting processes.

Benefits include:

- Real-time inventory accuracy exceeding 99%

- Automated reordering when stock reaches thresholds

- Reduced labor costs associated with manual counts

- Instant visibility into stock locations and movements

Automated Sorting and Package Verification

Vision-enabled robotic systems can detect, classify, and route packages based on size, shape, destination, or packaging type without human intervention. These systems adapt to varying package dimensions and can process thousands of items per hour.

Leading logistics providers like Amazon and Walmart leverage computer vision for automated sorting, dramatically increasing throughput while reducing misrouted shipments.

Quality Control and Damage Detection

Computer vision systems inspect packages for defects, damage, incorrect labeling, or seal integrity before shipment. Deep learning models trained on historical defect data can spot anomalies with precision far beyond human capabilities, reducing return rates and enhancing customer satisfaction.

Curious about the data powering these intelligent systems? Discover What Kind of Data is Needed to Train an Effective AI Model for Supply Chain Optimization?

Enhanced Safety and Compliance

Vision systems monitor warehouses for safety hazards like spills, blocked exits, or improper equipment usage. They can verify workers are wearing proper protective gear and detect unauthorized access or suspicious activities, creating safer work environments.

Robotic Picking and Packing

Computer vision guides robotic arms to accurately identify, grasp, and manipulate items of varying shapes and sizes. This enables lights-out operations where automated systems handle picking, packing, and palletizing with minimal human supervision.

The Business Impact: Why Computer Vision Matters

Organizations investing heavily in AI for supply chain operations report 61% higher revenue growth compared to peers, according to IBM. Computer vision specifically delivers:

- Operational efficiency: Faster processing speeds and reduced cycle times

- Cost reduction: Lower labor costs and decreased error-related expenses

- Scalability: Ability to handle volume spikes without proportional headcount increases

- Customer satisfaction: Improved accuracy and faster fulfillment

- Data-driven insights: Rich visual data feeding predictive analytics

To understand how these insights connect to broader supply chain intelligence, read How Predictive Analytics Works for Logistics.

How debales.ai Leverages Computer Vision for Smarter Logistics

At debales.ai, we integrate computer vision capabilities within our AI-powered logistics platform to deliver:

- Real-time visual monitoring of warehouse operations with instant alerts

- Automated quality verification reducing defects and returns

- Intelligent inventory tracking eliminating manual counts

- Seamless integration with existing warehouse management systems

- Predictive maintenance through visual equipment monitoring

Our solutions bridge the gap between automation and intelligence—transforming raw visual data into actionable operational insights that drive continuous improvement.

Want to see the difference between basic automation and AI-powered intelligence? Explore What's the Difference Between AI, Machine Learning, and Automation in a Warehouse Context?

Future Trends: The Evolution of Visual AI in Logistics

The future points toward fully autonomous warehouses where computer vision-powered drones conduct inventory audits, AI systems dynamically optimize workflows, and robotics handle material movements with minimal human intervention.

Integration with IoT devices and digital twin technology will create even more sophisticated simulation and optimization capabilities, enabling predictive decision-making at unprecedented scales.

Moving Forward with Visual Intelligence

Computer vision represents a fundamental shift in how logistics operations achieve visibility, accuracy, and efficiency. Organizations embracing this technology position themselves for sustainable competitive advantage in an increasingly automated industry.

The question isn't whether to adopt computer vision—it's how quickly your organization can leverage it effectively.

Ready to see how computer vision can transform your warehouse operations?

Discover how debales.ai's AI-powered platform brings visual intelligence to life, delivering measurable improvements in accuracy, efficiency, and cost savings.

Book a demo with debales.ai today and experience the future of intelligent logistics operations.

All blog posts

View All →

Friday, 28 Nov 2025

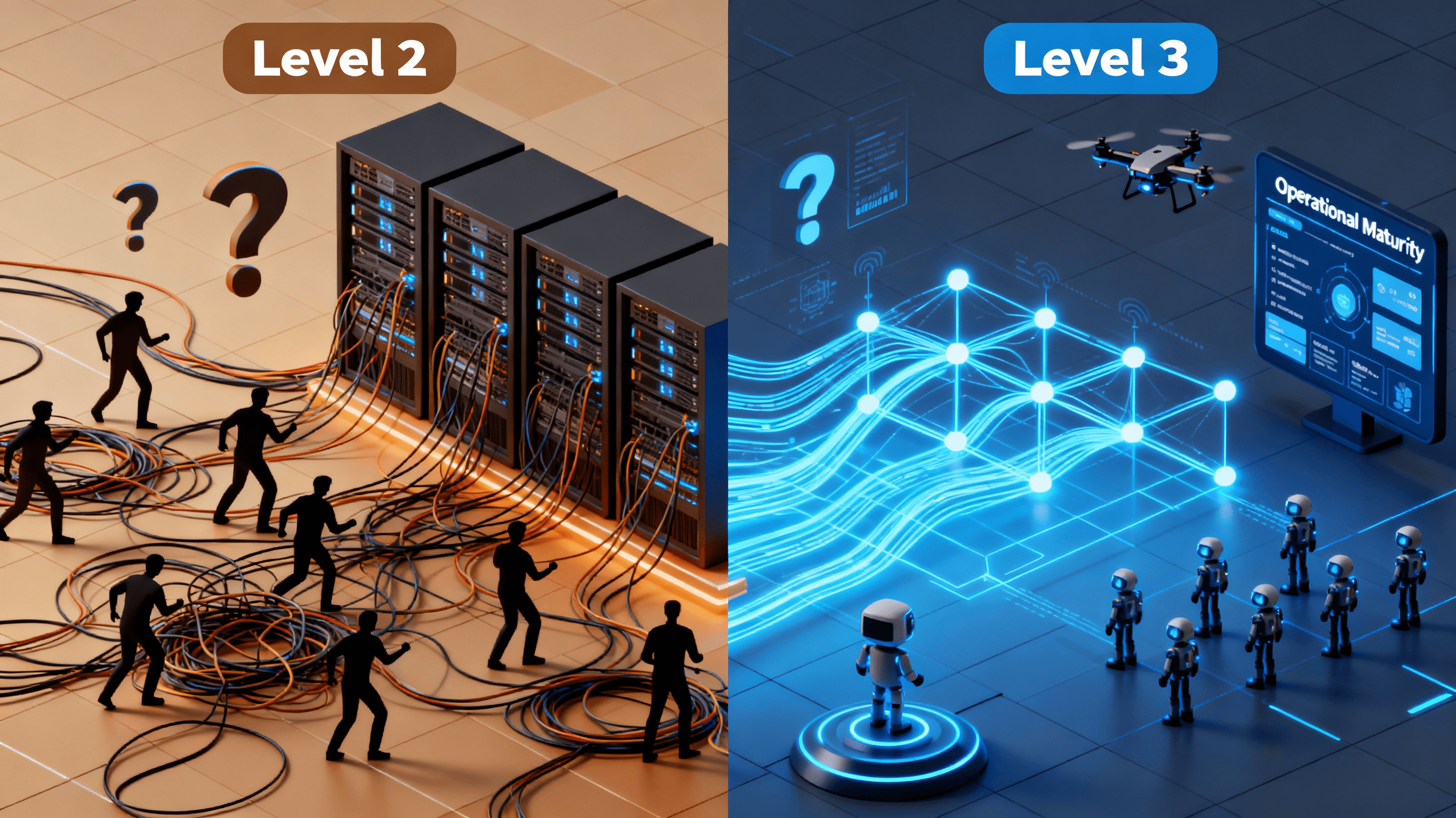

The 90-Day Roadmap: Moving from Ad-Hoc AI to Operational Excellence

Stuck in AI experimentation? Learn how to escape Level 2 maturity using the Mess-O-Meter to diagnose chaos, prioritize with triangulation, and scale in 90 days.

Thursday, 27 Nov 2025

Mess-O-Meter Deep Dive: Real Logistics Examples for Digital Maturity

Discover Mess-O-Meter examples diagnosing digital chaos in logistics—baseline workflows, benchmark maturity, create AI roadmaps with real steps for transformation success.

Wednesday, 26 Nov 2025

Multi-Agent AI via Email: End-to-End Automation for Logistics Complexity

Explore agentic orchestration where autonomous email AI agents coordinate freight, customs, insurance, and carriers—automating multi-party processes for resilient supply chains.