How Robots and AI Are Transforming Warehouse Operations?

Monday, 29 Sep 2025

|

How Robots and AI Are Transforming Warehouse Operations

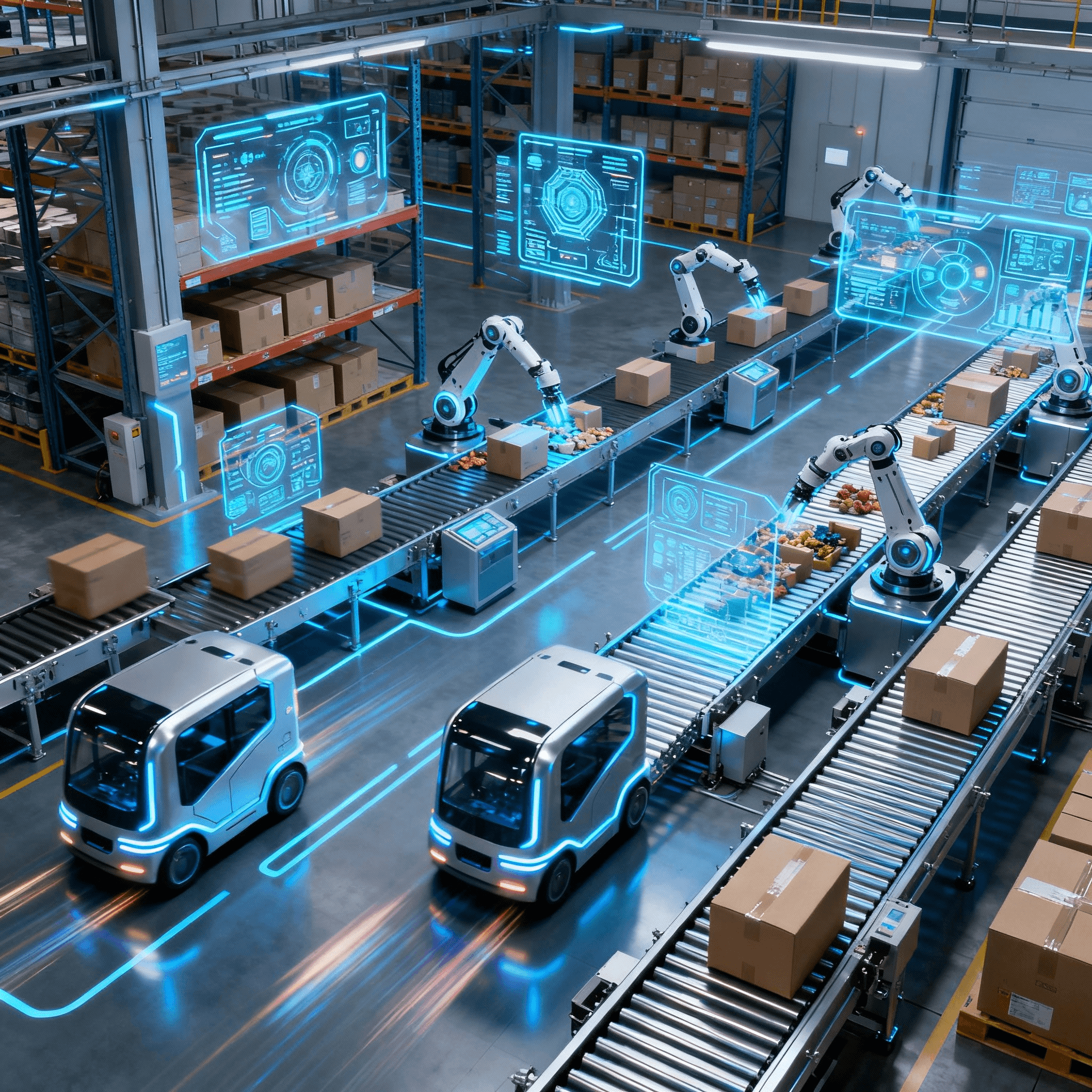

The warehouse floor is undergoing its most dramatic transformation in decades. Walk into a modern fulfillment center today and you'll witness a choreographed dance between humans and machines—autonomous robots gliding seamlessly between aisles, robotic arms picking items with superhuman precision, and AI systems orchestrating thousands of simultaneous tasks with split-second decision-making.

This isn't incremental improvement. It's revolutionary change driven by the convergence of artificial intelligence, computer vision, and advanced robotics. Organizations implementing AI-powered warehouse automation report 30-50% labor cost reductions, 99%+ accuracy rates, and the ability to operate 24/7 without breaks or fatigue.

For logistics leaders facing labor shortages, rising customer expectations for same-day delivery, and razor-thin margins, understanding how robots and AI transform warehouse operations isn't academic curiosity—it's survival strategy in an increasingly automated industry.

Wondering what separates today's intelligent robots from yesterday's rigid automation? The answer lies in AI's ability to learn, adapt, and optimize in real-time within unpredictable warehouse environments.

The Evolution: From Fixed Automation to Intelligent Robotics

Traditional warehouse automation relied on pre-programmed machinery following fixed paths—conveyor systems, automated guided vehicles (AGVs) on magnetic strips, and rigid robotic systems requiring highly structured environments.

These legacy systems faced critical limitations:

- Inflexible paths requiring costly infrastructure changes

- Inability to adapt to layout modifications or new product types

- No decision-making capability when encountering exceptions

- Required uniform product packaging and handling conditions

AI-powered robotics represents a fundamental paradigm shift:

Modern warehouse robots integrate machine learning, computer vision, and real-time data processing to enable intelligent, adaptable performance. They don't just execute commands—they learn, predict, and optimize continuously.

For context on this evolution, explore What's the Difference Between AI, Machine Learning, and Automation in a Warehouse Context?.

Core Technologies Driving Warehouse Transformation

1. Autonomous Mobile Robots (AMRs)

AMRs represent the most visible transformation in warehouse operations—self-navigating robots that transport goods between locations without human intervention or fixed guide paths.

How AMRs work:

- Advanced sensors and cameras create real-time 3D maps of warehouse environments

- AI navigation algorithms calculate optimal paths dynamically, avoiding obstacles

- LiDAR and computer vision enable safe collaboration with human workers

- Cloud connectivity allows fleet coordination and continuous learning

Functions AMRs perform:

- Material transport between receiving, storage, picking, and shipping zones

- Order picking assistance—traveling to storage locations and carrying items to packing stations

- Real-time inventory counting and cycle counting

- Sorting products by destination or shipping method

- Returns handling and cross-docking operations

Business impact: Amazon deploys over 750,000 mobile robots across its fulfillment network, enabling 24/7 operations and dramatically increasing throughput per square foot.

Learn more about the visual intelligence powering AMRs in How Computer Vision Technology Helps in Logistics Operations.

2. AI-Powered Robotic Picking Systems

Perhaps the most challenging warehouse task to automate has been picking—selecting individual items from storage and preparing them for shipment. AI has finally cracked this challenge.

Advanced capabilities:

- Computer vision systems identify objects regardless of shape, size, or orientation

- Deep learning models recognize products even with varying packaging or damage

- Robotic grippers adapt to different textures, weights, and fragility levels

- Real-time learning improves pick success rates continuously

The results: AI-powered robotic arms achieve consistent pick rates exceeding human speed while reducing damage and errors. Unlike older systems requiring uniform packaging, these machines recognize thousands of different items and handle them appropriately.

Example: Ocado, the UK online grocer, uses AI-powered robotic picking systems that handle over 65,000 products per week per robot with 99.9% accuracy.

3. Automated Storage and Retrieval Systems (AS/RS)

Modern AS/RS combines robotics with AI-powered warehouse management systems to maximize storage density and retrieval speed.

Key features:

- Vertical storage maximizing cubic space utilization

- AI algorithms optimizing product placement based on velocity and order patterns

- Automated retrieval delivering items to picking stations in seconds

- Real-time inventory tracking eliminating counting errors

4. AI-Driven Warehouse Management Systems (WMS)

The brain behind warehouse robotics, AI-powered WMS orchestrates all activities with superhuman coordination.

Intelligence layers:

- Predictive demand forecasting positioning inventory before orders arrive

- Dynamic task allocation assigning work to humans and robots optimally

- Real-time route optimization for people and machines

- Continuous learning improving performance from every transaction

Understand the broader orchestration capabilities in What is an AI-Powered Control Tower in Logistics?.

Measurable Business Outcomes

Organizations implementing AI-powered warehouse robotics report transformational improvements:

Productivity and Efficiency Gains

- 30-50% increase in order fulfillment speed

- 24/7 operation capability without shift limitations

- 2-3x improvement in space utilization through vertical storage and optimized layouts

- 40-60% reduction in order cycle times

Cost Reduction

- 25-40% labor cost savings as robots handle repetitive tasks

- 30-50% reduction in training costs as standardized robotic processes require less human expertise

- 20-35% decrease in operational expenses through improved efficiency

- Rapid ROI with many implementations paying back within 18-24 months

Accuracy and Quality

- 99%+ picking accuracy eliminating costly errors

- 95%+ inventory accuracy through continuous automated counting

- 70-80% reduction in product damage from gentle robotic handling

- Near-elimination of shipping errors

Scalability and Flexibility

- Instant capacity scaling during peak seasons without hiring

- Rapid adaptation to new products through AI learning

- Easy layout modifications as AMRs don't require fixed infrastructure

- Modular expansion adding robotics capacity incrementally

For insights into how predictive capabilities enable these improvements, read How AI Improves the Accuracy of Demand Forecasting.

Real-World Transformation Examples

Amazon: The Robotics Pioneer

Amazon operates one of the world's most automated fulfillment networks:

- 750,000+ robots across 200+ fulfillment centers globally

- Kiva robots transport entire shelving units to human pickers

- AI-powered sortation systems routing millions of packages daily

- Computer vision systems automatically scanning and verifying every item

Results: 20% improvement in operational efficiency, enabling same-day delivery expansion to millions more customers.

Walmart: Scaling Intelligent Automation

Walmart deployed autonomous robots across 4,700+ stores and distribution centers:

- Autonomous floor scrubbers freeing associates for customer service

- Shelf-scanning robots checking inventory and pricing

- AI-powered sorting systems in regional distribution centers

- Automated micro-fulfillment centers for e-commerce orders

DHL: Global Logistics Automation

DHL implemented collaborative robots (cobots) in 350+ locations worldwide:

- LocusBots working alongside human pickers

- 50% productivity improvement in fulfillment operations

- Reduced training time from weeks to hours

- Flexible deployment across varying warehouse sizes

Discover how route optimization complements warehouse automation in Real-World Examples of AI Route Optimization.

Addressing Common Concerns

"Will Robots Replace Human Workers?"

The reality is more nuanced. Robots excel at repetitive, physically demanding tasks, while humans handle complex problem-solving, quality judgment, and customer-focused activities.

The partnership model:

- Robots handle heavy lifting, long-distance transport, and repetitive picking

- Humans manage exceptions, quality control, and strategic decisions

- Overall employment often increases as warehouses expand capacity enabled by automation

Labor shortage solution: With 73% of warehouse operators unable to fully staff operations, robotics solves the availability problem rather than displacing willing workers.

"Is the Technology Too Expensive for Mid-Size Operations?"

Robotics pricing has dropped dramatically while capabilities have increased:

- Robotics-as-a-Service (RaaS) models eliminate large capital investments

- Modular deployment allows starting small and scaling gradually

- 18-24 month ROI typical even for medium-sized warehouses

- Labor savings often fund the automation investment

"What About Implementation Complexity?"

Modern robotic systems are designed for rapid deployment:

- No infrastructure modifications required for AMRs

- Quick integration with existing WMS platforms

- Minimal disruption during phased rollouts

- Cloud-based management simplifying ongoing operations

How debales.ai Enables Intelligent Warehouse Operations

At debales.ai, our AI platform provides the intelligence layer that maximizes robotic warehouse efficiency:

Predictive Inventory Positioning: AI forecasts place products optimally before orders arrive, reducing robot travel distances

Dynamic Task Orchestration: Intelligent allocation of work between humans, AMRs, and robotic systems based on real-time conditions

Continuous Performance Optimization: Machine learning analyzing every operation to identify efficiency improvements

Seamless Integration: Connecting with robotic fleets, WMS, and ERP systems for unified visibility and control

Explainable AI: Transparent decision-making showing why robots are routed or tasks allocated in specific ways

Our approach combines the automation intelligence detailed in In What Ways Does AI Automate and Improve Inventory Management? with robotic coordination capabilities.

The Future: Fully Autonomous Warehouses

The trajectory points toward "lights-out" warehouses operating with minimal human intervention:

Emerging capabilities:

- Drones for ceiling-level inventory management

- Swarm intelligence with hundreds of robots coordinating autonomously

- Self-learning systems continuously optimizing layouts and processes

- Predictive maintenance preventing robot downtime before failures occur

This vision aligns with the digital twin concept explored in What is a Digital Twin and How is it Used in Logistics AI?.

Strategic Imperatives for Warehouse Leaders

The competitive gap between automated and manual warehouses grows wider daily. Organizations that delay robotics adoption risk permanent disadvantages in cost structure, throughput capacity, and customer service levels.

Action steps:

Assess current operations identifying high-impact automation opportunities

Pilot with modular, scalable solutions demonstrating ROI quickly

Partner with technology providers offering proven implementations

Invest in workforce upskilling for human-robot collaboration

Plan for continuous automation expansion as technology advances

Ready to transform warehouse operations from labor-intensive to intelligently automated?

Discover how debales.ai's AI platform maximizes the ROI of warehouse robotics through predictive intelligence, dynamic orchestration, and continuous optimization.

Book a demo with debales.ai today and experience how AI and robotics create the warehouse of the future—faster, smarter, and more efficient than ever imagined.

All blog posts

View All →

Saturday, 21 Feb 2026

Why detention keeps hitting your P&L (and how to stop it)

Detention and accessorials keep spiking because appointments, docs, and visibility break down. Here’s a practical playbook to cut fees this month.

Saturday, 21 Feb 2026

Stop Paying Detention: Fix Your Yard-to-Dock Handoff

Detention and accessorials keep rising because dock schedules and real-time arrival data don’t match. Here’s how ops teams can fix it fast.

Saturday, 21 Feb 2026

Why your freight data is lying to you (and costs)

Freight data gaps drive detention, billing disputes, and missed ETAs. Learn why it keeps happening and what to fix this week across TMS, WMS, and carriers.