Predictive Maintenance at Scale: Cut Fleet Downtime 40% with AI

Monday, 27 Oct 2025

|

Introduction: Turning Maintenance from a Cost Center into a Competitive Weapon

For logistics companies, unscheduled fleet downtime is a multi-billion-dollar profit killer. Every hour a truck, plane, or ship is out of service, it's not just the direct repair costs that accumulate; it's the missed delivery windows, the furious customers, the supply chain bottlenecks, and the cascading operational chaos that truly cripple the bottom line. Traditional maintenance—a reactive cycle of "break-fix" or a rigid, calendar-based preventive schedule—is utterly failing to meet the demands of a 24/7 logistics world. But a new era of maintenance is here, one that doesn't just fix problems but prevents them entirely. By leveraging Predictive Maintenance at Scale, powered by autonomous AI agents, leading logistics firms are now reducing fleet downtime by an astounding 40% and transforming their maintenance operations from a necessary evil into a powerful competitive advantage.

This is not science fiction. This is the new reality of fleet management, where AI agents act as the central nervous system for your entire distributed asset network. They autonomously monitor vehicle health, predict component failures with pinpoint accuracy, schedule service, procure parts, and coordinate with technicians—all without human intervention. For logistics CEOs, CXOs, and COOs, this represents a fundamental shift in operational strategy. This in-depth analysis will dissect the mechanics of AI-driven predictive maintenance, provide a clear ROI framework, and offer a practical roadmap to implementation. It's time to move beyond reacting to failures and start building a fleet that is intelligent, resilient, and relentlessly reliable.

The Crippling Inadequacies of Traditional Fleet Maintenance

The traditional approach to fleet maintenance falls into two outdated camps, both of which are deeply flawed in today's high-velocity logistics environment.

Reactive Maintenance ("Break-Fix"): This is the most primitive and costly model, where assets are run until they fail. The direct costs of an unexpected breakdown are enormous—emergency towing, premium labor rates, and expedited parts shipping. But the indirect costs are even more devastating. A single downed truck can delay dozens of high-priority shipments, trigger SLA penalties, damage customer relationships built over years, and throw downstream warehouse and delivery schedules into disarray. This model is not a strategy; it's a constant state of crisis management.

Preventive Maintenance: A step up from reactive, this model services assets based on fixed schedules (e.g., every 10,000 miles or every 3 months). While it reduces catastrophic failures, it is wildly inefficient. It leads to over-maintenance, where perfectly good components like brake pads or tires are replaced prematurely, wasting money on unnecessary parts and labor. More critically, it completely fails to account for the unique operating conditions of each asset. A truck running mountainous routes in harsh winter weather wears down far differently than one operating on flat highways in a mild climate, yet the preventive schedule treats them identically, leaving the door wide open for unforeseen breakdowns between scheduled service intervals.

Both models are blind. They lack the intelligence to see what's really happening inside an asset and are incapable of adapting to the dynamic reality of logistics operations. This blindness is what AI-powered predictive maintenance is designed to cure.

The AI Predictive Maintenance Engine: From Data to Diagnosis

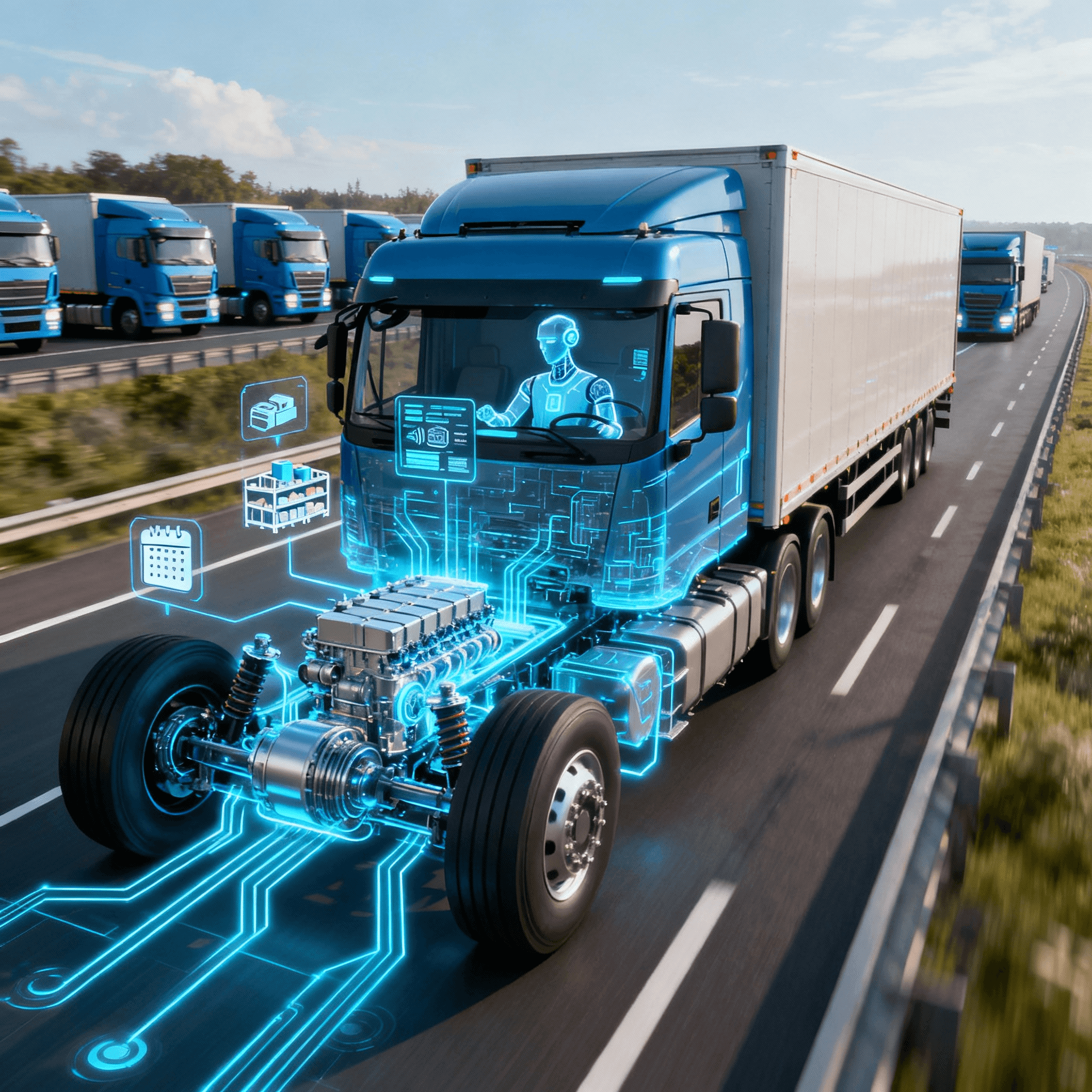

AI-driven predictive maintenance works by creating a high-fidelity "digital twin" of every asset in the fleet and using machine learning to forecast its future state. This engine is fueled by a constant stream of data from a wide array of sources.

- Telematics and IoT Sensor Data: Modern vehicles are packed with sensors that provide real-time data on everything from engine RPM and oil pressure to tire temperature and brake pad wear.

- Audio and Vibrational Analysis: Sophisticated AI agents can even "listen" to an engine's sound or analyze its vibration patterns. A subtle, inaudible change in a sound frequency can be a tell-tale sign of an impending bearing failure days or even weeks before it happens.

- Driver Behavior Data: The system analyzes how a vehicle is being driven. Aggressive acceleration and hard braking patterns place different stresses on a vehicle than smooth, consistent driving, and the AI factors this into its failure predictions.

- Operational and Environmental Data: The AI incorporates the vehicle's route history, cargo weight, and even the weather conditions it has operated in to build a complete picture of the stresses it has endured.

- Historical Maintenance Records: Every past repair and service event is fed into the model, allowing it to learn the unique failure patterns of specific vehicle makes, models, and components.

By feeding this torrent of data into advanced machine learning algorithms—like anomaly detection and survival analysis models—the AI agent can predict the remaining useful life (RUL) of critical components with over 95% accuracy. It doesn't just tell you that a truck has a problem; it tells you that the alternator on Truck 753 has a 92% probability of failing in the next 150 operating hours. This predictive power is the trigger for a fully autonomous maintenance workflow.

The Power of Autonomy: End-to-End Maintenance Orchestration

Predicting a failure is only half the battle. The true revolution of AI-powered maintenance lies in the agent's ability to autonomously act on that prediction, orchestrating the entire service lifecycle without a single human touchpoint.

Autonomous Maintenance Scheduling

Once the AI agent predicts an impending failure, it doesn't just send a passive alert. It accesses the vehicle's operational schedule in the TMS and analyzes its future routes. The agent then identifies the optimal time and location for service to minimize operational disruption. For example, it might determine that Truck 753 is scheduled to have a 6-hour layover near a certified service center in three days. It automatically designates this window for the repair, ensuring the asset is serviced during planned downtime rather than being pulled from active service.

Automated Parts Procurement

Simultaneously, the maintenance agent initiates the parts procurement process. It knows the exact part number required for the repair and integrates with the inventory management systems of multiple parts suppliers. The agent can:

- Check internal inventory for the required part.

- If not available, query external suppliers' systems for price and availability.

- Automatically select the supplier that offers the optimal balance of cost and delivery speed to ensure the part arrives at the service center before the truck does.

- Autonomously generate and issue a purchase order.

This "just-in-time" parts delivery eliminates the need to carry expensive safety stock and prevents delays caused by waiting for parts to arrive.

Intelligent Service Coordination

With the schedule set and parts on their way, the AI agent coordinates the actual service event. It connects to the service center's scheduling system and books the maintenance appointment. It transmits the vehicle's diagnostic data and the specific work order directly to the technician's system, so they know exactly what needs to be done the moment the truck arrives. Once the service is complete, the agent receives a digital confirmation, updates the vehicle's maintenance record, and processes the payment to the service center, closing the loop on a fully autonomous workflow.

The Overwhelming ROI of Predictive Maintenance at Scale

The financial returns from implementing an autonomous predictive maintenance system are multi-layered and substantial.

- 40% Reduction in Unplanned Downtime: By shifting from reactive to predictive, companies can virtually eliminate costly roadside breakdowns.

- 25% Reduction in Maintenance Costs: Servicing assets based on actual need rather than a fixed schedule reduces unnecessary labor and parts replacement.

- 15% Improvement in Asset Utilization: Keeping vehicles on the road generating revenue instead of sitting in a repair shop directly boosts the top line.

- 30% Reduction in Parts Inventory: Just-in-time parts procurement slashes inventory holding costs and eliminates waste from obsolescence.

- 50% Increase in Maintenance Team Productivity: Automating scheduling and coordination frees up fleet managers to focus on strategic vendor management and process improvement rather than administrative firefighting.

For a mid-sized fleet of 500 trucks, these efficiencies can easily translate into $2-4 million in bottom-line impact annually, delivering a full return on investment in under 12 months.

Explore More on Debales.ai

- Can AI Predict When Delivery Trucks Need Maintenance?

- Voice AI and Audio Intelligence for Predictive Maintenance in Logistics 2025

- Autonomous Rerouting AI: Instant Supply Chain Resilience 2025

- Self-Healing Supply Chains: AI Systems for Real-Time Disruption Resolution

- AI Agent Economics: Real Cost Savings Beyond Automation in Logistics

Turn Your Fleet into a Self-Maintaining Asset

Stop letting unplanned downtime dictate your profitability. It's time to empower your fleet with the intelligence to maintain itself.

Discover Your Predictive Maintenance ROI with Debales.ai

Conclusion: The Era of the Self-Maintaining Fleet is Here

Predictive maintenance at scale, orchestrated by autonomous AI agents, represents one of the most powerful and achievable transformations available to the logistics industry today. By moving beyond outdated break-fix and preventive models, organizations can dramatically increase asset uptime, slash operational costs, and build a reputation for unparalleled reliability. This is not just about fixing trucks more efficiently; it's about building a truly intelligent, resilient, and self-optimizing logistics operation that is primed for dominance in the decade to come.