The Hidden 5-10%: AI Agents Uncover Overlooked Logistics Savings

Monday, 27 Oct 2025

|

Introduction: Unlocking the Final Frontier of Logistics Efficiency

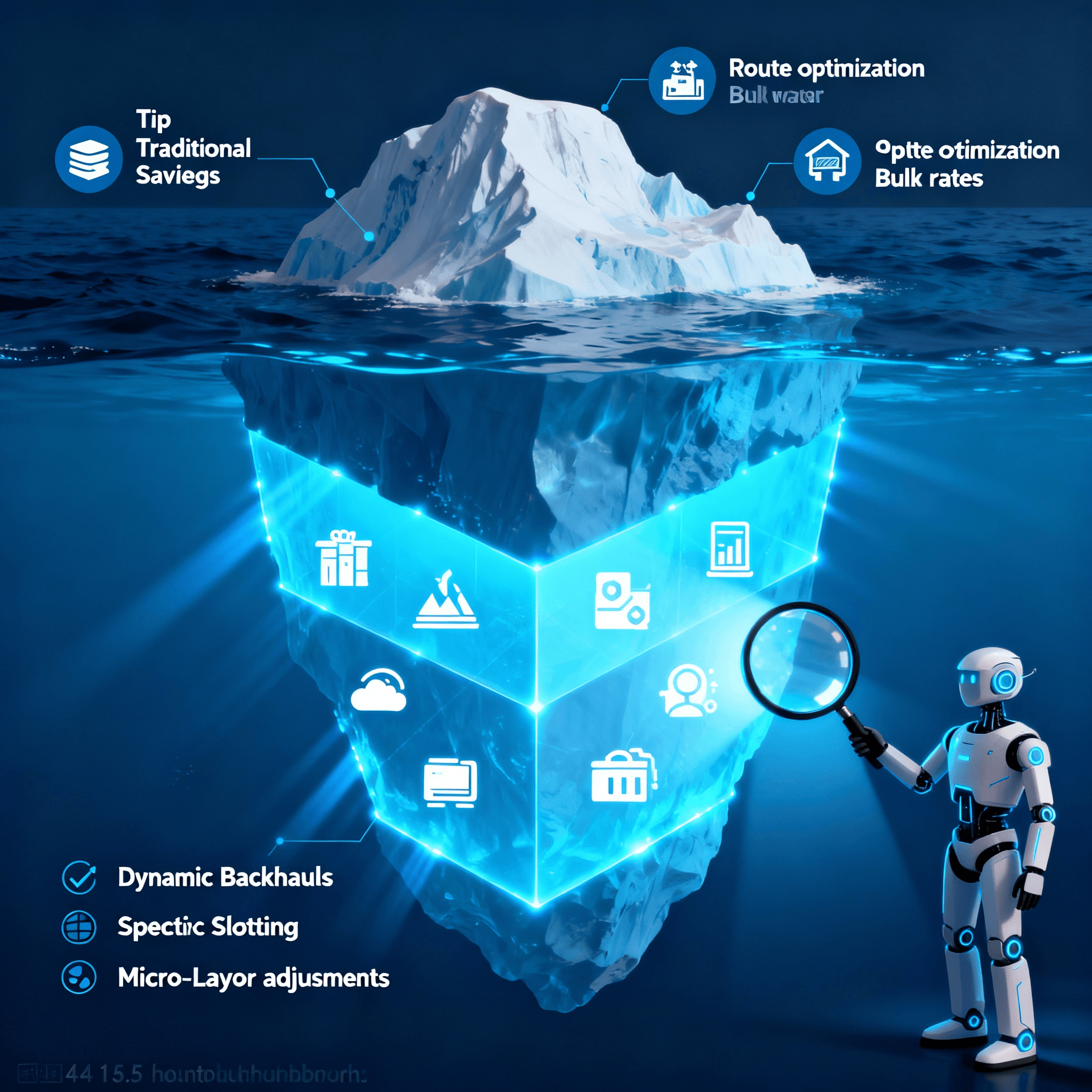

While traditional automation has optimized the most visible aspects of logistics, AI agents are now unlocking an additional 5-10% in cost savings by targeting non-obvious, interconnected inefficiencies that human analysis and legacy systems consistently miss. This "hidden 5-10%" represents billions of dollars trapped in suboptimal decisions across freight, inventory, warehousing, and labor operations—areas where complex, dynamic variables have defied conventional optimization. For logistics executives, capturing these savings is the key to achieving a decisive competitive advantage in a market where margins are razor-thin and every percentage point matters.

This deep-dive analysis reveals where these overlooked opportunities lie and how autonomous AI agents, powered by advanced machine learning, are uniquely equipped to find and exploit them. Drawing on real-world examples from industry leaders and insights from top-tier research, we will provide a roadmap for CEOs, CXOs, and COOs to move beyond surface-level savings and into the realm of profound, systemic optimization. As the logistics industry hurtles toward a future dominated by autonomous decision-making, understanding and capturing this hidden 5-10% is not just an incremental gain; it is a strategic imperative for survival and growth.

Beyond the Obvious: Why Traditional Methods Fall Short

For years, logistics optimization has focused on the "low-hanging fruit"—automating repetitive tasks, negotiating bulk freight rates, and implementing basic inventory management rules. These methods, while valuable, operate on a set of static assumptions and fail to account for the complex, second-order effects that ripple across the supply chain. Human planners, constrained by cognitive limits and siloed data, can only optimize within their immediate domain, while legacy TMS and WMS are bound by rigid, pre-programmed logic.

This is where the hidden 5-10% in savings resides: in the micro-inefficiencies, the suboptimal trade-offs, and the unseen correlations that only an AI agent, capable of processing millions of data points in real-time, can identify. For example, a traditional approach might optimize a delivery route for the lowest cost, but an AI agent can simultaneously factor in the probability of delay, the cost of potential customer churn from that delay, the impact on downstream warehouse labor scheduling, and the opportunity cost of not using that truck for a more profitable backhaul. It is in this multi-dimensional optimization that AI agents find savings that are invisible to traditional methods.

Uncovering Hidden Savings in Freight and Transportation

The True Cost of Empty Miles and Suboptimal Backhauls

Empty miles are a well-known drain on profitability, but AI agents go beyond simple backhaul matching to find non-obvious opportunities that can reduce empty miles by a further 15-20%. Instead of just looking for a return load along the same corridor, AI agents analyze the entire network, identifying triangular or even more complex routes that may seem inefficient at first glance but result in a higher overall asset utilization and profitability. By continuously analyzing market spot rates, driver availability, and real-time demand, agents can dynamically create and bid on these complex routes, turning what would have been a costly empty return into a profitable multi-stop journey.

Dynamic Lane and Carrier Portfolio Optimization

Logistics companies often rely on fixed contracts with a preferred set of carriers for specific lanes, a practice that provides stability but often misses out on market dynamism. AI agents continuously analyze the performance, real-time availability, and fluctuating spot market rates of thousands of potential carriers. They can identify that for a specific type of shipment on a Tuesday afternoon, a smaller, regional carrier is consistently 8% cheaper and 12% faster than the contracted primary carrier. By making thousands of these micro-adjustments to the carrier mix every day, AI agents can unlock an additional 3-5% in annual freight spend without sacrificing reliability.

The Granular World of Inventory and Warehousing Efficiencies

Predictive Slotting and SKU Velocity Analysis

Static warehouse slotting, where products are assigned to a fixed location, is a major source of hidden inefficiency. AI agents perform predictive slotting by continuously analyzing SKU velocity, seasonality, and co-purchase patterns. They can predict that a certain low-volume SKU will suddenly spike in demand in the next 48 hours and proactively move it to a forward-picking location, reducing travel time for pickers by up to 30%. Furthermore, agents can analyze returns data to identify products that are frequently returned together and ensure they are not stored next to each other, preventing picking errors and reducing the high cost of reverse logistics.

Optimizing for the "Last 100 Feet"

While route optimization focuses on the journey between facilities, AI agents optimize the "last 100 feet"—the movement of goods within a warehouse or distribution center. By analyzing video feeds and sensor data, computer vision-enabled agents can identify subtle bottlenecks in real-time, such as congestion in a specific aisle or an inefficient layout at a packing station. The agent can then run thousands of simulations to recommend minor adjustments—like changing the direction of travel in an aisle or repositioning a frequently used tool—that can collectively boost overall warehouse throughput by 5-7%.

Reimagining Labor and Operational Workflows

Dynamic Labor Scheduling and Skill Matching

Traditional labor scheduling is often based on historical averages and rigid shift patterns, leading to periods of costly overstaffing or service-degrading understaffing. AI agents create dynamic labor schedules by analyzing real-time order flows, inbound shipment ETAs, and even local weather forecasts that might impact employee commute times. More importantly, the agent can match specific tasks to the employees best suited to perform them based on historical performance data. By assigning the fastest, most accurate pickers to the most complex orders, for example, an AI agent can improve overall labor productivity by 8-12%.

Eradicating "Tribal Knowledge" and Process Deviations

Every logistics operation has undocumented "tribal knowledge"—the shortcuts and workarounds that experienced employees use to get the job done. While sometimes effective, this creates process inconsistencies and makes the operation dependent on a few key individuals. AI agents, equipped with computer vision, can observe and learn these optimized workflows, codify them, and then use augmented reality glasses or handheld devices to train the entire workforce on the best-known method for every task. This standardizes excellence and captures an additional 4-6% in efficiency that was previously locked away as informal knowledge.

Explore More on Debales.ai

- AI Agent Economics: Real Cost Savings Beyond Automation in Logistics

- The 90-Day AI Agent Implementation Roadmap: Accelerating Time-to-Value

- AI Agent Capabilities vs. Legacy TMS: The New Competitive Battleground

- Monetizing AI Agent Capabilities: From Cost Center to Profit Engine

- Why Leading 3PLs Are Allocating 15-20% of IT Budgets to AI Agents in 2025

Discover Your Hidden Savings with Debales.ai

Are you leaving 5-10% of your potential profits on the table? Partner with debales.ai to deploy intelligent agents that uncover the non-obvious cost savings your current systems are missing.

Conclusion: The New Imperative for Profitability

The pursuit of logistics efficiency has entered a new era. The obvious optimizations have been made, and the next wave of significant cost savings lies hidden in the complex interplay of operational variables. AI agents, with their ability to perform multi-dimensional, real-time analysis, are the only tools capable of unlocking this final 5-10% of efficiency. For logistics leaders, embracing this technology is not just about incremental improvement; it is about redefining what is possible and securing a sustainable cost advantage in an increasingly competitive landscape.

All blog posts

View All →

Tuesday, 3 Mar 2026

Why accessorials keep wrecking your freight margins

Detention, TONU, reweighs, and lumper fees keep killing margin. Here is why it happens and how to control accessorials this week.

Tuesday, 3 Mar 2026

Why our freight data keeps lying (and what to do)

Late ETAs, surprise accessorials, and messy invoices start with bad freight data. Here’s how ops teams can fix it without new headcount.

Tuesday, 3 Mar 2026

Why accessorials keep blowing up your freight budget

Detention, lumper, reclass, and redelivery fees keep creeping in. Learn why accessorials happen and how to cut disputes and overcharges fast.