Top 5 Benefits of Implementing AI in Logistics

Friday, 3 Oct 2025

|

What Are the Top Five Benefits of Implementing AI in Logistics?

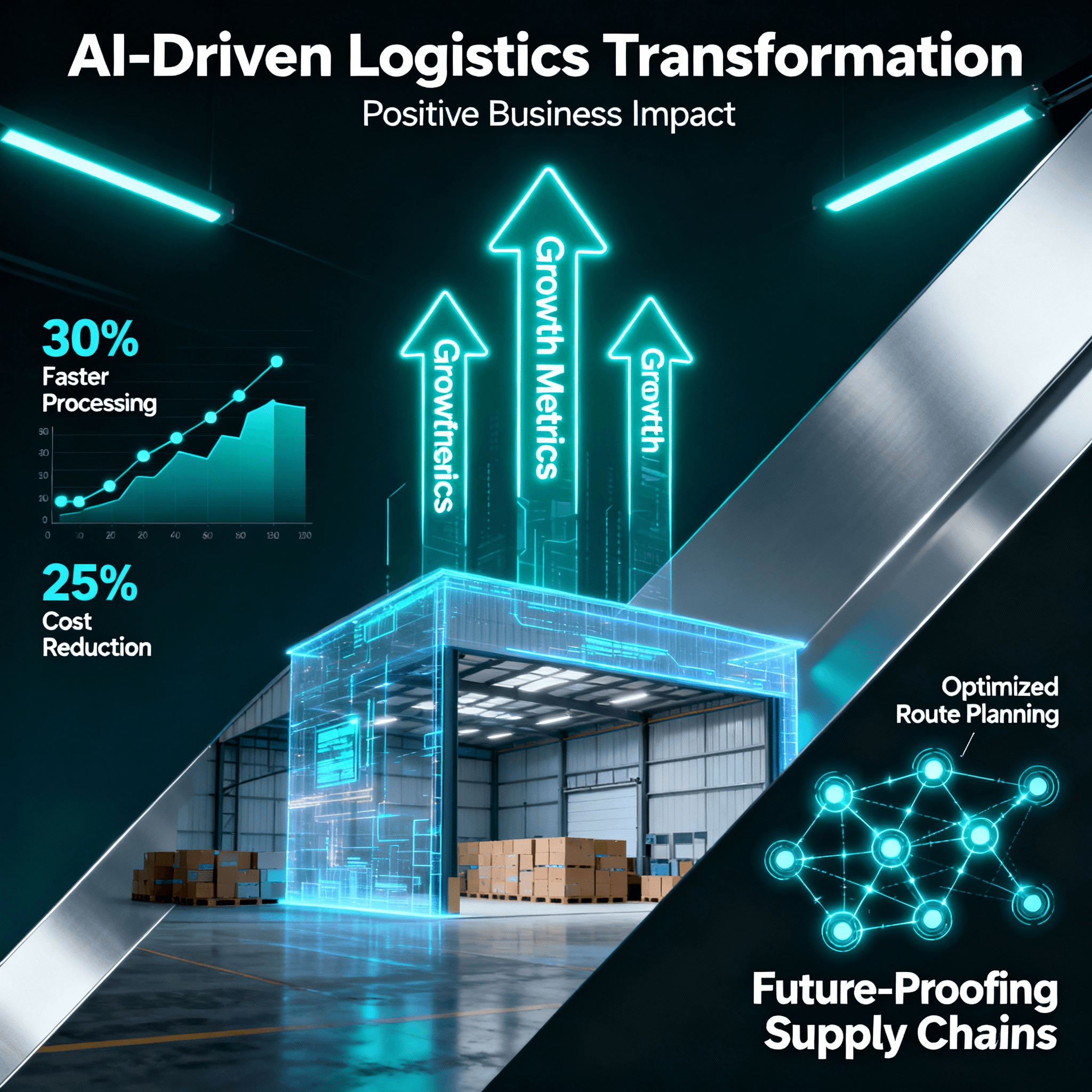

The business case for AI in logistics isn't theoretical—it's measured in billions. McKinsey research reveals 61% of manufacturing executives report decreased costs while 53% report increased revenues directly from AI implementation, with over one-third seeing revenue gains exceeding 5%. The numbers tell a compelling story: up to 30% reduction in inventory costs, 50% operational cost savings, 65% service level improvements, and 20-50% better forecast accuracy.

Yet despite overwhelming evidence, many logistics organizations remain trapped in analysis paralysis—endlessly evaluating AI while competitors capture market share through operational advantages. The global AI in logistics market, projected to reach $20.8 billion by 2025, isn't growing because of hype—it's expanding because early adopters are realizing measurable, transformational benefits that translate directly to bottom-line performance.

For CEOs, CXOs, and COOs navigating mounting pressure to control costs while improving service, understanding AI's top five benefits isn't academic exercise—it's strategic roadmap for competitive survival in an industry being fundamentally reshaped by intelligent automation.

Wondering which AI benefits deliver fastest ROI or create most sustainable competitive advantages? The answer lies in five interconnected value drivers that compound into transformational business outcomes.

The Logistics Industry's Transformation Imperative

Before exploring specific benefits, understanding the context driving AI adoption is crucial. Modern logistics faces unprecedented challenges:

Rising Customer Expectations: Same-day delivery, real-time tracking, and perfect order fulfillment are now baseline requirements, not differentiators

Cost Pressures: Fuel costs, labor shortages, and margin compression force continuous efficiency improvements

Supply Chain Volatility: Geopolitical tensions, natural disasters, and market disruptions demand unprecedented agility

Labor Shortages: Difficulty finding and retaining qualified workers across warehouses, transportation, and operations

Sustainability Mandates: Regulatory requirements and corporate commitments demanding carbon emission reductions

Traditional approaches—adding capacity, hiring more people, or accepting higher costs—no longer work. AI represents the only scalable solution delivering simultaneous cost reduction and service improvement.

For context on AI's role in logistics, explore What Exactly Is AI in Logistics and Supply Chain Management?.

Benefit #1: Dramatic Operational Cost Reduction (15-50% Savings)

The most immediate and measurable AI benefit is substantial cost reduction across multiple operational areas.

How AI Reduces Costs

Route Optimization: AI analyzes traffic patterns, weather conditions, and delivery constraints to generate optimal routes reducing fuel consumption by 15-25%

Predictive Maintenance: Machine learning predicts equipment failures before they occur, reducing maintenance costs by 25% and eliminating expensive emergency repairs

Inventory Optimization: AI-powered demand forecasting reduces inventory levels by up to 30% while simultaneously improving availability, freeing significant working capital

Labor Efficiency: Automation of routine tasks—order processing, documentation, tracking inquiries—reduces manual workloads by 40-60%, allowing teams to focus on strategic initiatives

Freight Cost Optimization: AI freight procurement and dynamic carrier selection reduce transportation costs by 15-25%

Real-World Cost Impact

UPS: ORION AI route optimization system saves 100 million miles and 10 million gallons of fuel annually, translating to $300-400 million in annual cost savings

Industry Benchmark: Logistics companies implementing AI reduce operational costs by 15-50% depending on scope and maturity of implementation

McKinsey Research: 44% of executives whose companies adopted AI report measurable cost reductions

Discover route optimization impact in Real-World Examples of AI Route Optimization.

Calculating Your ROI

Organizations typically see AI ROI within 12-18 months, with payback periods shortening as implementation matures. To calculate potential savings, visit How Much Does AI Really Cost in Logistics? ROI Calculator and Real Examples.

Benefit #2: Enhanced Operational Efficiency (30-50% Productivity Gains)

Beyond cost reduction, AI fundamentally transforms operational performance—enabling organizations to do more with existing resources.

Efficiency Improvements Across Operations

Warehouse Operations: AI-powered robotics and computer vision increase throughput by 30-50% while improving picking accuracy to 99%+. Amazon operates 750,000+ robots across its fulfillment network, dramatically accelerating order processing

Demand Forecasting: AI improves forecast accuracy by 20-50%, enabling better production planning, inventory positioning, and capacity allocation

Order Allocation: Machine learning automatically assigns orders to optimal fulfillment locations and delivery resources, improving fulfillment speed by 25-40%

Documentation Processing: AI automates invoice processing, customs documentation, and compliance paperwork, reducing processing time by 70-80%

Decision-Making Speed: Real-time AI analytics enable faster, data-driven decisions—minutes instead of days for complex route planning or inventory adjustments

Productivity Multipliers

FedEx: Predictive analytics accurately forecast demand and allocate resources, leading to significant operational performance improvements

Lennox Industries: Machine learning implementation achieved 16% service level improvement and 26% inventory turn increase while supporting 250% distribution network growth

Industry Average: AI-driven logistics solutions improve operational efficiency by up to 30% through better resource allocation and smarter routing

Explore warehouse automation in How Robots and AI Are Transforming Warehouse Operations.

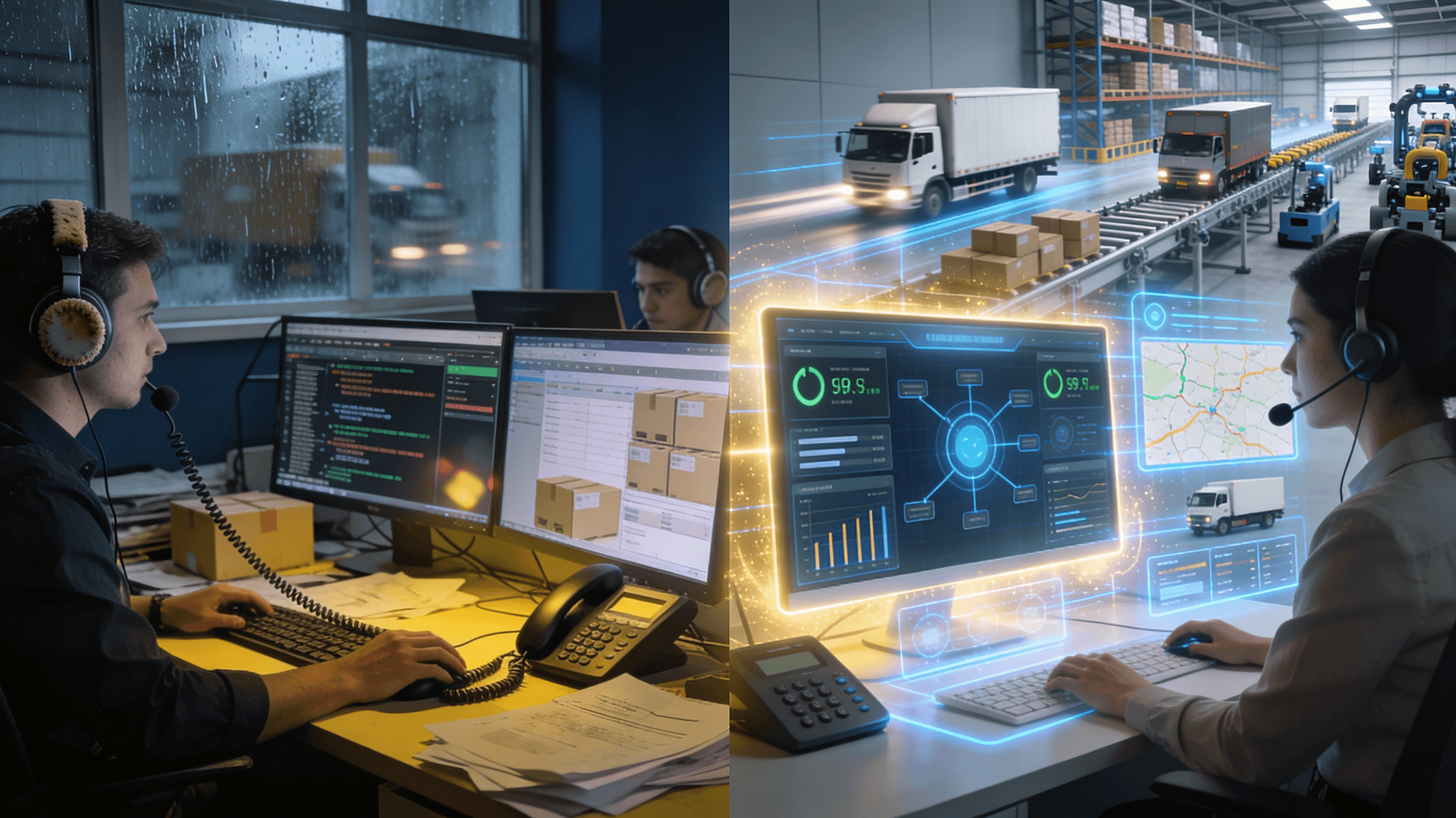

Benefit #3: Superior Customer Experience (65% Service Level Increase)

AI transforms customer experience from reactive service to proactive satisfaction—a critical differentiator in competitive markets.

Customer Experience Enhancements

Real-Time Tracking: AI-powered visibility provides customers with accurate, continuous shipment updates and predictive delivery windows

Proactive Communication: Intelligent systems automatically alert customers about delays, delivery windows, or required actions before they need to inquire

24/7 Service: AI chatbots handle 80% of routine customer inquiries instantly, eliminating wait times and providing consistent support across time zones

Personalized Recommendations: Machine learning analyzes customer preferences to suggest optimal shipping options, delivery times, and product alternatives

Reduced Errors: 99%+ order accuracy through automated picking, packing, and quality verification minimizes costly delivery mistakes

Business Impact

Service Level Gains: Companies implementing AI boost service levels by up to 65%, dramatically improving customer satisfaction and retention

Response Time: AI accelerates customer service interactions by 30%, providing instant answers to tracking, billing, and documentation questions

Customer Satisfaction: Organizations report 25-40% improvement in satisfaction scores through faster, more reliable delivery and transparent communication

Learn about customer service automation in Can Generative AI Help Create Logistics Reports or Handle Customer Service Inquiries?.

Benefit #4: Significant Inventory Optimization (20-35% Reduction)

AI fundamentally improves inventory management—reducing carrying costs while simultaneously improving availability, a seemingly impossible combination with traditional methods.

Inventory Intelligence

Demand Prediction: Machine learning forecasts demand with 20-50% better accuracy than traditional statistical methods, enabling optimal stock positioning

Dynamic Safety Stock: AI continuously adjusts safety stock levels based on actual demand variability and supplier reliability, reducing excess inventory by 20-30%

Multi-Echelon Optimization: Algorithms optimize inventory placement across distribution networks, reducing total system inventory while improving service

Automated Replenishment: AI triggers restocking orders at optimal times based on predicted demand and lead times, eliminating manual monitoring

Obsolescence Prevention: Predictive analytics identify slow-moving items early, enabling proactive clearance before products become unsellable

Financial Benefits

Inventory Reduction: Companies implementing AI reduce inventory levels by 20-35% while maintaining or improving service levels

Working Capital: 30% inventory reduction in a $100M inventory operation frees $30M in working capital for strategic investments

Holding Costs: Lower inventory directly reduces warehousing, insurance, obsolescence, and financing costs

Example: Amazon's AI-driven inventory systems maintain lean operations while supporting explosive growth and same-day delivery expansion

Discover inventory intelligence in In What Ways Does AI Automate and Improve Inventory Management?.

Benefit #5: Enhanced Supply Chain Resilience (30-40% Faster Response)

Perhaps AI's most strategic benefit is building resilient supply chains capable of thriving during disruptions rather than merely surviving them.

Resilience Capabilities

Predictive Risk Detection: AI forecasts supply chain disruptions 60-90 days early—supplier failures, weather events, geopolitical risks—enabling proactive mitigation

Real-Time Monitoring: Continuous visibility across supply networks detects anomalies instantly, triggering immediate response protocols

Scenario Simulation: Digital twins enable stress testing contingency plans before disruptions occur, validating response strategies

Automated Response: AI autonomously executes contingency actions—rerouting shipments, reallocating inventory, switching suppliers—without waiting for human decision cycles

Adaptive Forecasting: Machine learning adjusts demand predictions dynamically during volatility, maintaining planning accuracy when traditional models fail

Competitive Advantage

Response Speed: AI-integrated supply chains respond 30-40% faster to disruptions compared to traditional approaches relying on manual processes

Forecast Accuracy: Companies using AI maintain 20-50% better forecast accuracy during market volatility

Preparedness: 98% of mature AI users feel prepared for geopolitical disruption, compared to 0% with no AI implementation plans

Revenue Protection: Real-time risk mitigation protects revenue streams by preventing disruption-related stockouts, production shutdowns, and customer defections

Explore risk management in How AI is Used to Manage Risk and Disruptions in the Supply Chain.

The Compounding Effect: Benefits That Multiply

These five benefits don't exist in isolation—they compound into transformational business outcomes:

Cost Reduction + Efficiency = Profitability: Lower costs combined with higher throughput dramatically improve margins

Efficiency + Customer Experience = Market Share: Superior service delivered efficiently enables competitive pricing and customer loyalty

Inventory Optimization + Forecasting = Cash Flow: Less inventory with better availability frees working capital while protecting revenue

Resilience + Efficiency = Sustainability: Optimized operations responding proactively to disruptions reduce environmental impact while maintaining profitability

All Benefits Combined = Competitive Advantage: Organizations excelling across all dimensions create sustainable competitive moats impossible for laggards to overcome

Implementation Considerations

Realizing these benefits requires structured implementation:

Start with High-Impact Use Cases: Focus initial AI deployment on areas delivering fastest ROI—route optimization, demand forecasting, warehouse automation

Ensure Data Quality: AI effectiveness depends on data quality—invest in data infrastructure before deploying models

Phased Approach: Begin with pilots demonstrating value before scaling across full operations

Change Management: Prepare teams for AI collaboration—upskilling staff and addressing cultural resistance

Continuous Improvement: AI systems improve over time—establish processes for ongoing refinement and expansion

For comprehensive implementation guidance, explore our blog series covering specific AI applications across logistics operations.

Real-World Success Summary

The benefits aren't hypothetical—they're proven across industry leaders:

Amazon: 750,000+ robots, AI-powered forecasting, and logistics optimization enabling market-leading fulfillment speed and cost structure

UPS: $300-400M annual savings from ORION route optimization, demonstrating ROI at massive scale

FedEx: Predictive analytics improving operational performance and customer service through better demand forecasting

Walmart: $1B+ supply chain savings through AI-powered inventory, logistics, and supplier management optimization

Industry Consensus: Multiple research firms (McKinsey, Gartner, SAP) documenting consistent 15-50% cost reductions, 30% efficiency gains, and 65% service improvements

Strategic Imperative: The Cost of Inaction

While AI adoption accelerates, the cost of delayed implementation grows exponentially. Organizations still operating without AI face widening competitive disadvantages:

Cost Gap: Competitors achieving 15-50% lower costs can undercut pricing or invest savings in growth

Service Gap: 65% service level improvements by AI-enabled competitors attract and retain customers

Efficiency Gap: 30% productivity advantages compound into massive throughput differences

Resilience Gap: 30-40% faster disruption response protects revenue when others suffer

The competitive reality: AI isn't optional technology—it's fundamental infrastructure for survival in modern logistics.

Ready to capture these transformational benefits for your logistics operations?

Discover how debales.ai's AI-powered platform delivers measurable cost reduction, efficiency gains, service improvements, inventory optimization, and supply chain resilience—transforming logistics from operational challenge into competitive advantage.

Book a demo with debales.ai today and experience the five benefits of AI reimagined for your logistics operations. Let's calculate your specific ROI together.