Why So Many 3PLs Still Struggle With Freight Visibility

Thursday, 12 Feb 2026

|

70% of 3PLs Still Report Visibility Gaps. Why?

Despite all the innovation in transportation tech, a 2025 FreightWaves survey found that 70% of third-party logistics providers still experience frequent visibility blackouts in their freight tracking systems. That means loads go dark, clients ask for updates, and your teams scramble for answers—with limited data.

What’s Broken in Freight Visibility

The promise of real-time freight visibility has existed for years, but many 3PL operators know the reality doesn’t match the hype. Loads often disappear in transit due to poor ELD integrations, outdated carrier systems, or simple human errors. When that happens, customer service reps and operations teams lose hours chasing location updates manually.

Another common issue? Fragmented data across TMS, carrier portals, and emailed updates. Without a unified source of truth, teams can't confidently track a shipment’s true status—especially during handoffs in multimodal or drayage operations.

The result: frustrated customers, delayed exception handling, and reactive firefighting instead of proactive planning.

What the Industry Numbers Say

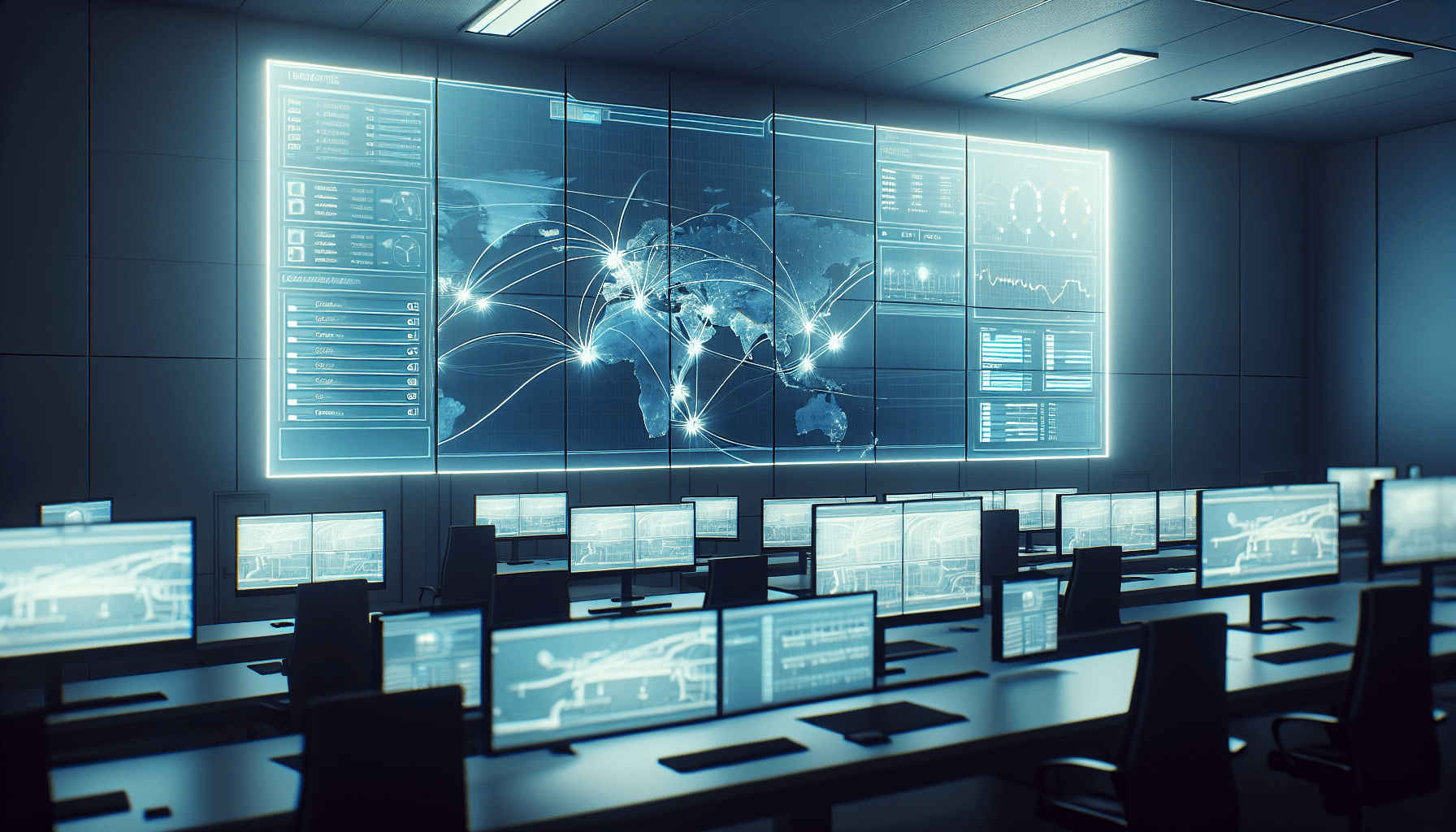

The visibility gap isn't just anecdotal—it’s measurable:

- According to a FourKites report, only 29% of freight shipments globally were tracked with consistent real-time visibility in 2024.

- A Gartner survey revealed that 64% of supply chain leaders cite poor visibility as a top risk to performance.

- Hidden costs add up fast. A single missed update can mean an $85 call center ticket, delays in cross-docking, or idle time in drayage yards.

These friction points scale quickly across high-volume lanes. For freight brokers managing hundreds of LTL and FTL shipments weekly, even a 5% visibility gap creates dozens of phone calls, late updates, and unhappy customers.

The Path to Better Visibility

So how do you close the visibility gap without reinventing your tech stack?

- Unify sources of truth - Centralize carrier tracking, TMS data, and manual updates into one platform.

- Automate exception detection - Flag stuck or idle loads automatically before the issue escalates.

- Champion standardization - Work with partners that support API-fed location updates rather than emailed spreadsheets.

- Audit carrier compliance - Use scorecards to track which carriers consistently report accurate location data—and hold them accountable.

Ultimately, it's about getting proactive intelligence instead of reactive noise.

How Debales.ai Helps Logistics Teams

That’s exactly what Debales.ai was built for. Our AI-powered freight intelligence system connects to your existing TMS and carrier network, analyzing thousands of data points from BOLs, GPS pings, and event logs.

Instead of just showing you when a truck departed or arrived, we highlight high-risk loads, late carriers, and silent routes. One 3PL customer saved 8 hours per week previously spent tracking shipments manually across email and spreadsheets. Another cut late-update complaints by 40%.

The bottom line? You spend less time chasing updates—and more time improving reliability.

Actionable Steps for 3PL Leaders

If you're a logistics manager or supply chain director tired of bad data and blind spots, here’s what you can implement this quarter:

- Run a visibility audit: Check your current tracking completeness across carriers and modes.

- Map your exception triggers: What counts as “high risk”? Late pickups? No update in 2+ hours?

- Set internal SLAs for updates: Define how often location data should refresh—and track it.

- Centralize your view: Integrate TMS, WMS, and ELD feeds into one interface, even if it’s via middleware.

- Use predictive alerts: Don’t just show where the freight is—flag what’s likely to go wrong and why.

These steps don't require million-dollar implementations. They start with understanding where you’re blind—and fixing the flow of data.

Freight Visibility Doesn’t Have to Be This Hard

The tech exists. The data is there. What most 3PLs need is a smarter way to pull it together.

If you’re still relying on dispatcher texts, PDF BOLs, and spreadsheets to track freight, you're not alone—but you're also not stuck. With the right strategy and tools, you can move from chasing updates to controlling outcomes. And that’s how visibility becomes a competitive advantage, not just a checkbox.