Stop Losing Freight Time to Manual Scheduling

Thursday, 12 Feb 2026

|

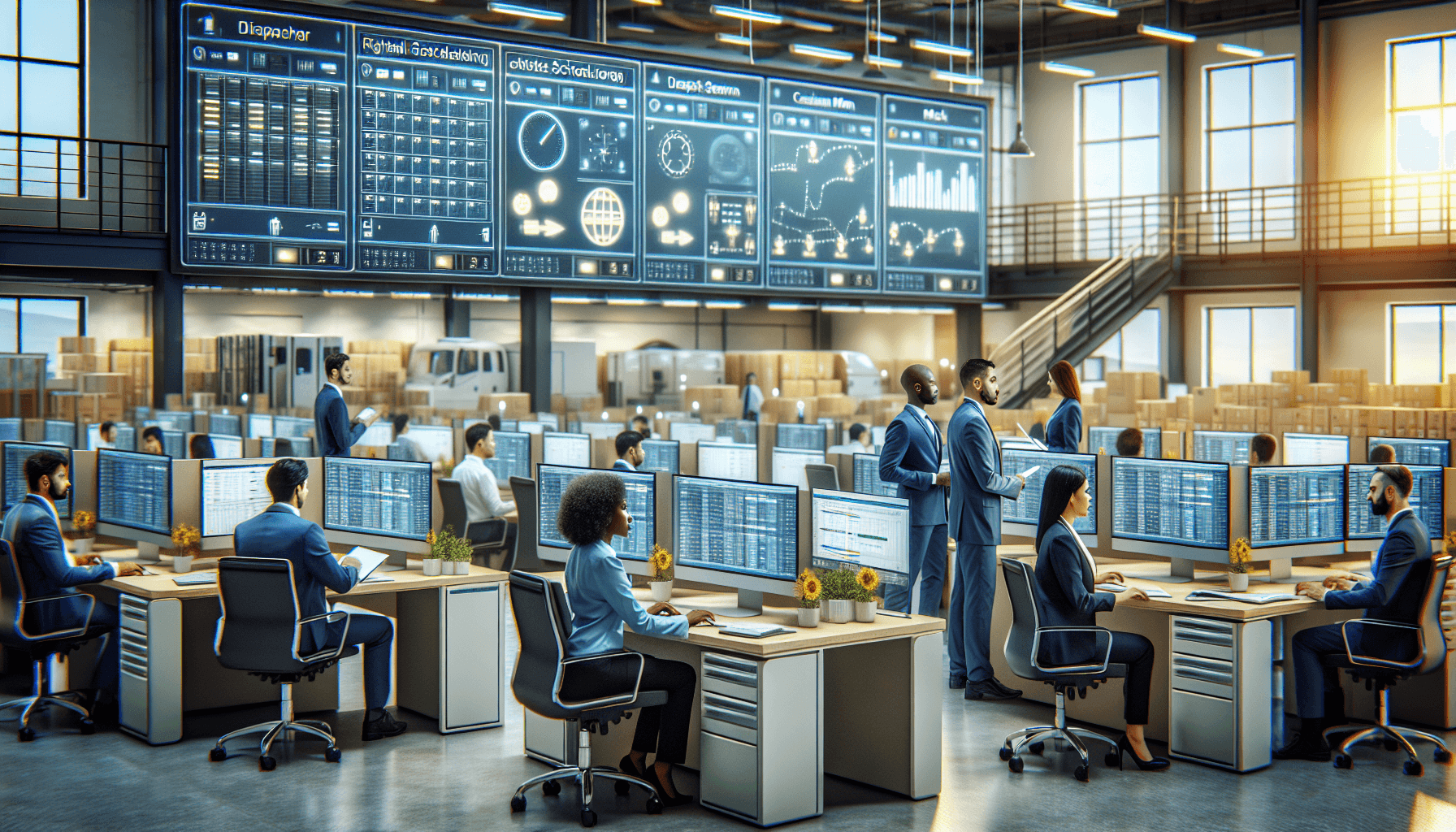

Over 30% of a dispatcher’s day is spent manually scheduling freight

That’s nearly three hours lost daily to emails, calls, and chasing appointment confirmations. For a 3PL managing 20+ loads a day, that adds up fast — in time, missed pickups, and burned-out teams.

And let's be honest: no one got into freight management to copy-paste BOL references into scheduling portals.

The real cost of outdated scheduling workflows

Manual scheduling isn’t just inefficient — it creates ripple effects across your entire operation:

- Loads arrive late at warehouses because appointment confirmations are delayed.

- Drivers sit idle waiting for docks, driving up detention costs.

- Customer service fields more "Where's my truck?" calls because updates are buried in inboxes.

A typical mid-size broker loses 10-15% productivity across their operations due to these lags, according to McKinsey.

It's not a lack of effort. It's that the tools and workflows most teams rely on just haven't evolved alongside the rest of the supply chain tech stack.

The industry logjam: disconnected systems and reactive workflows

Despite the push toward automation, many freight teams still rely on spreadsheets, siloed TMS modules, and manual carrier portals to coordinate schedules. A 2023 Gartner report found that only 23% of logistics providers use automated appointment scheduling consistently.

Why? Because most legacy systems weren’t designed to play nicely with others. And integrating real-time scheduling data across TMS, WMS, and ERP platforms often feels more complicated than the problem it's meant to solve.

Plus, warehouse constraints (limited dock slots, rigid receiving hours) make scheduling feel like a high-stakes game of Tetris that resets daily.

A smarter solution: integrate and automate from the middle

Instead of relying on phone calls and portal logins, progressive logistics teams are reducing friction by automating the scheduling process at the communication layer.

Here’s what that looks like:

- System-neutral appointment booking: Sync pickup and delivery appointments across carrier portals, DC systems, and TMS platforms without needing every system to fully integrate.

- Rules-driven automations: Set predefined rules for carrier access, warehouse slots, and SLA windows. The system handles the back-and-forth.

- Real-time visibility: Get instant alerts when appointments are confirmed or conflict with service levels — no more waiting for email replies.

It’s not about ripping out your existing tech stack. It’s about overlaying a smart coordination layer that plugs gaps and speeds decisions.

Where Debales.ai fits in

Debales.ai streamlines freight scheduling by automating the repetitive workflows that slow down dispatchers and warehouse teams. It integrates with your existing TMS or scheduling platform to surface smarter booking recommendations, coordinate across systems, and reduce carrier communication overhead.

Customers using Debales.ai are saving up to 9 hours per week per dispatcher, cutting appointment-related errors by 40%, and improving on-time performance by 12% within the first 60 days.

The platform becomes the connective tissue between teams, systems, and stakeholder expectations — without requiring a full system overhaul.

4 ways logistics leaders can start improving now

- Audit your current appointment workflows: Where is time wasted? Who is chasing confirmations? Identify bottlenecks.

- Consolidate communication tools: If you're still juggling email threads, phone calls, and portal logins, look for tools that centralize scheduling tasks.

- Set carrier self-booking rules: Faster doesn’t mean less control. Use business logic to allow vetted carriers to self-schedule within service parameters.

- Track scheduling KPIs: Start with a simple one: How long does it take from booking a load to confirming an appointment? Track it weekly.

Scheduling should never be the bottleneck

You already optimize for route efficiency, capacity matching, and cost-per-mile. Why let something as controllable as freight scheduling drag down your operation?

By removing the manual lift, smart 3PLs and logistics teams are speeding up cycles, improving service levels, and freeing their teams to focus on value-added work.

Because let’s face it: freight moves faster when the schedule’s smarter.