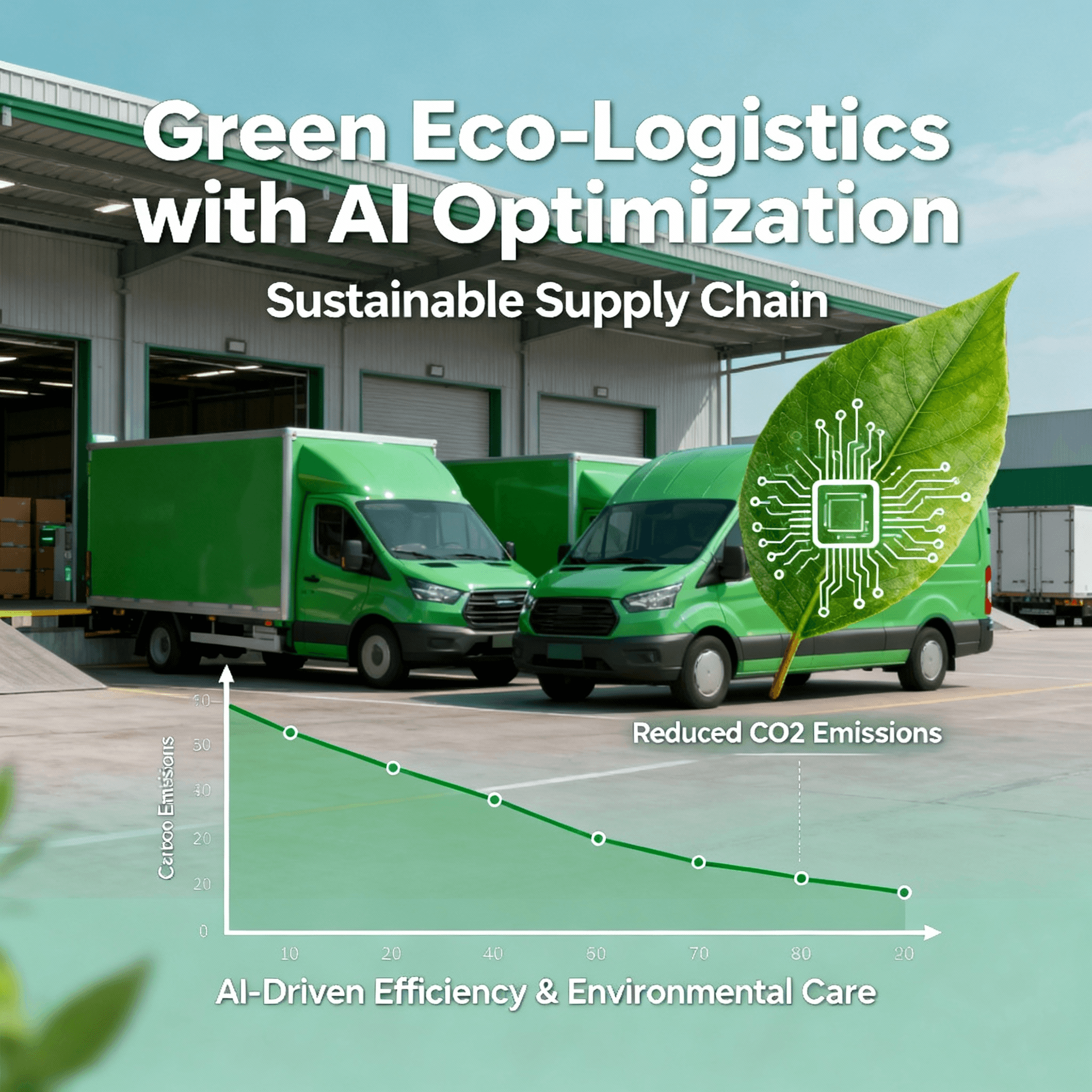

In What Ways Does AI Improve Sustainability in Logistics? (e.g., Reducing Carbon Footprint)

Friday, 3 Oct 2025

|

In today's world, sustainability is no longer just a buzzword—it’s a key factor influencing business decisions, especially in industries like logistics. As a CEO, CXO, or COO, leading a company that champions both operational excellence and environmental responsibility is essential. Thankfully, Artificial Intelligence (AI) offers a pathway to make logistics operations more sustainable while driving efficiency.

But how exactly does AI improve sustainability in logistics? The logistics industry is known for its high energy consumption and carbon footprint, from warehousing to transportation. AI is the game-changer that makes it possible to reduce this footprint significantly. Let’s dive into the top ways AI is transforming logistics into a greener, more efficient operation.

1. Optimizing Delivery Routes to Reduce Fuel Consumption

One of the most significant contributors to a logistics company's carbon footprint is transportation. AI-powered route optimization algorithms analyze real-time data, including traffic patterns, weather, and delivery schedules, to determine the most efficient routes. This means fewer miles driven, less fuel consumed, and ultimately, a reduction in carbon emissions.

For example, by leveraging AI-based systems, delivery fleets can avoid congested areas, minimize idling times, and reduce unnecessary detours. In turn, this leads to significant fuel savings, which also translates to lower greenhouse gas emissions.

Real-World Example: Companies like UPS use AI-powered route optimization tools that reduce fuel consumption and emissions, saving millions of dollars annually and cutting down on CO2 output.

2. Predictive Maintenance for Fleet Efficiency

A vehicle running on outdated or faulty equipment wastes energy and emits excess pollutants. AI-powered predictive maintenance systems can monitor vehicle performance in real time, alerting fleet managers about potential issues before they become costly repairs or safety risks. This ensures that vehicles are always running at optimal efficiency, reducing the chances of unexpected breakdowns, which can lead to unnecessary emissions.

Moreover, these AI systems can recommend the best times for maintenance, based on usage data, ensuring minimal downtime and maximizing fleet performance. A well-maintained fleet is more energy-efficient and environmentally friendly.

Real-World Example: DHL uses predictive maintenance powered by AI for its fleet, reducing the number of emergency repairs and keeping their vehicles running smoothly, reducing the environmental impact.

3. Smart Warehouse Energy Management

Warehouses are another critical area where AI can improve sustainability. AI systems help optimize energy consumption by analyzing warehouse activity and adjusting lighting, heating, and cooling in real time based on need. For example, AI can reduce energy usage during non-peak hours when fewer goods are being handled.

AI can also manage the operation of automated systems, such as robotics and conveyor belts, ensuring they operate only when necessary, thus conserving energy.

Real-World Example: Companies like Amazon are already using AI to optimize their warehouse operations, reducing energy consumption and improving the overall sustainability of their supply chains.

4. Sustainable Packaging Solutions with AI

AI can help companies develop more sustainable packaging solutions, reducing the use of harmful materials and minimizing waste. By analyzing packaging data, AI can help identify opportunities to switch to recyclable materials or redesign packaging to minimize its carbon footprint.

AI-driven systems also help optimize packaging sizes and reduce unnecessary materials, cutting down on both waste and transportation costs (since smaller, lighter packages require less fuel to transport).

Real-World Example: Procter & Gamble has been using AI to improve its packaging solutions, ensuring that products are packed in a way that minimizes material usage and energy consumption throughout the logistics process.

5. Demand Forecasting for Efficient Resource Allocation

AI excels at predicting demand with high accuracy. By forecasting demand patterns based on historical data, market trends, and other external factors, logistics companies can optimize inventory and resource allocation. Efficient forecasting leads to fewer stockouts and less overstocking, which helps avoid unnecessary transportation and storage, thereby reducing carbon emissions.

When resources are allocated more effectively, there is a reduction in the energy and emissions associated with unnecessary transportation and warehousing.

Real-World Example: Walmart utilizes AI-driven demand forecasting to streamline its logistics operations, resulting in more efficient resource allocation and fewer trips made for stock replenishment, reducing its environmental impact.

6. AI in Sustainable Last-Mile Delivery

The final leg of delivery, known as last-mile delivery, can contribute significantly to a company's carbon footprint. AI is transforming this segment by enabling more efficient delivery routing and utilizing eco-friendly transport options such as electric vehicles or drones.

AI can also help match delivery routes to the most sustainable mode of transportation available, reducing both carbon emissions and congestion in urban areas.

Real-World Example: Postmates has implemented AI to streamline last-mile delivery using electric vehicles and optimized routes, ensuring reduced emissions in urban areas.

7. Carbon Footprint Tracking and Reporting with AI

Tracking and reducing carbon footprints is now a business imperative. AI can provide companies with the tools to track carbon emissions across their entire supply chain—from manufacturing to delivery. These AI systems can monitor energy usage, waste production, and emissions data in real time, helping companies make data-driven decisions to minimize their environmental impact.

AI-generated insights can also be used to produce sustainability reports that comply with environmental regulations and share progress with stakeholders.

Real-World Example: FedEx uses AI to track and report on their carbon emissions, giving them the ability to make informed decisions that align with their sustainability goals.

The Bottom Line: AI is Key to Achieving Sustainability in Logistics

AI is reshaping logistics by not only enhancing efficiency but also driving significant strides in sustainability. From optimizing fuel consumption and energy usage to improving packaging and predictive maintenance, AI helps logistics companies reduce their carbon footprints while maintaining high levels of performance.

For CEOs, CXOs, and COOs, adopting AI solutions for sustainability is not just a trend—it’s a strategy that aligns operational goals with global environmental responsibility.

Ready to Embrace AI for a More Sustainable Supply Chain?

AI can help you make your supply chain greener while improving operational efficiency. If you're ready to explore how AI can reduce your logistics carbon footprint and drive sustainability, Book a demo and see how our AI-driven solutions can help.

For further insights on AI’s impact on logistics, check out our other blogs, such as AI-Powered Circular Supply Chains: Sustainability Meets Smart Logistics and How Predictive Analytics Works for Logistics, Driving Smarter Supply Chains.