What is an AI-Powered Control Tower in Logistics?

Friday, 26 Sep 2025

|

What is an AI-Powered Control Tower in Logistics?

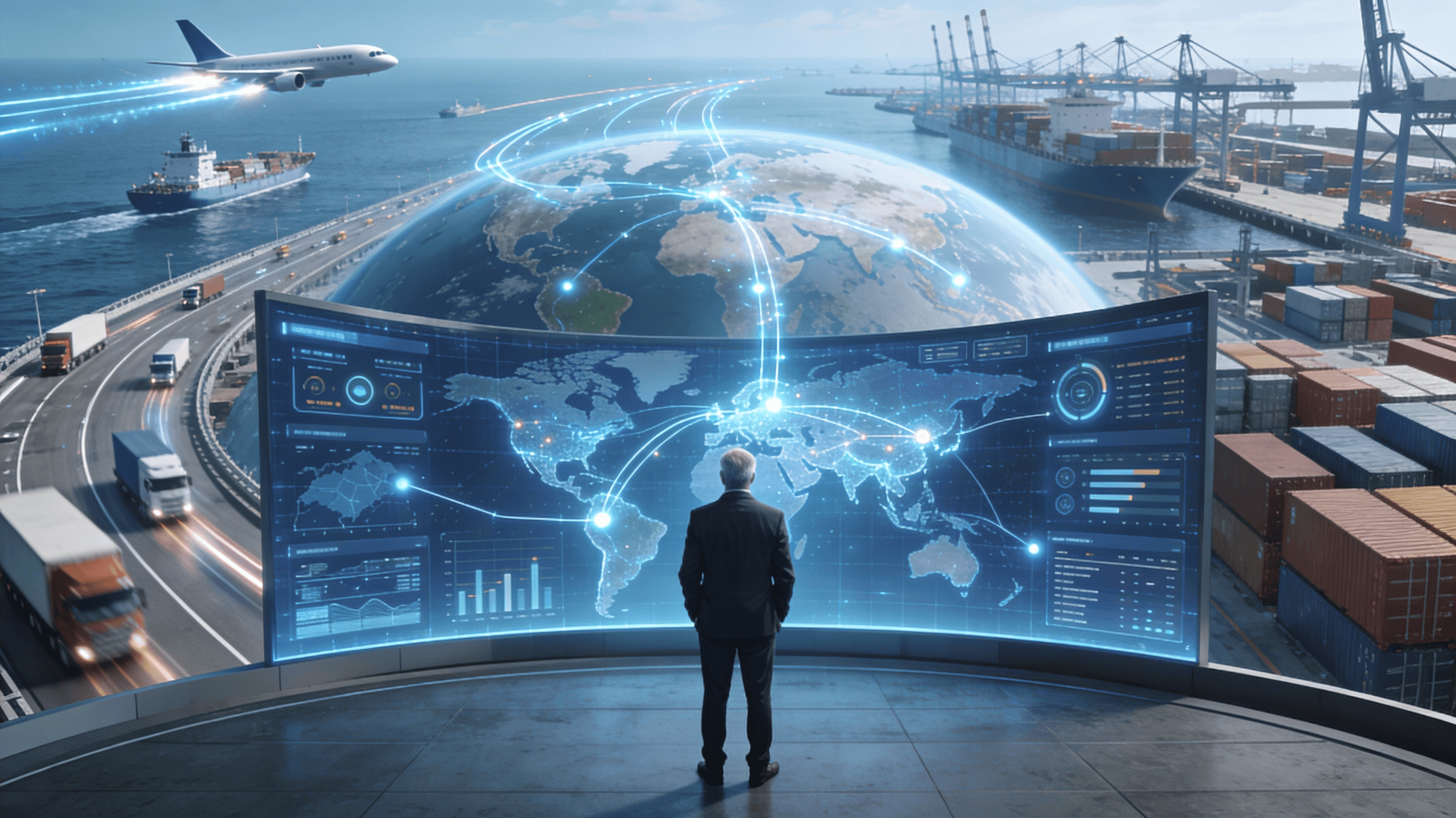

Imagine having a command center that monitors every shipment, predicts delays before they happen, automatically reroutes trucks around traffic, and alerts teams to disruptions across your entire supply chain—all in real time. This isn't a futuristic vision; it's the reality AI-powered control towers are delivering to logistics operations today.

An AI-powered control tower represents the evolution from passive monitoring dashboards to intelligent command centers that actively optimize supply chain operations. For organizations navigating increasingly complex global logistics, understanding this technology is critical for competitive survival.

Wondering what separates a control tower from traditional tracking systems? The difference lies in intelligence—the ability to predict, decide, and act autonomously.

Understanding the AI-Powered Control Tower

An AI-powered control tower is a centralized digital platform that aggregates real-time data from across the entire supply chain—ERP systems, transportation management systems (TMS), warehouse management systems (WMS), carrier networks, IoT sensors, weather services, and external data sources—then uses artificial intelligence to analyze, predict, and optimize operations.

Unlike traditional systems that simply display data, AI-powered control towers:

- Actively detect disruptions before they escalate

- Predict delays using historical patterns and real-time conditions

- Recommend or autonomously execute corrective actions

- Optimize across competing objectives (cost, speed, service quality)

- Learn continuously from every decision and outcome

For context on how AI enables these capabilities, explore What Exactly Is AI in Logistics and Supply Chain Management?.

How AI-Powered Control Towers Work

The intelligence operates through five interconnected stages:

1. Unified Data Integration

Pulls live data from all logistics systems, creating a single source of truth that eliminates information silos and manual data reconciliation.

2. Real-Time Monitoring

Tracks shipments across all transport modes (ocean, air, rail, road) with continuous visibility updates that eliminate the need for manual status checks.

3. Predictive Risk Detection

Uses AI algorithms to analyze congestion patterns, supplier reliability, weather forecasts, and historical trends to identify potential disruptions 48-72 hours before they occur.

4. Automated Decision-Making

Recommends or autonomously executes solutions—alternative routes, carrier substitutions, inventory reallocation—without waiting for human approval.

5. Continuous Optimization

Identifies inefficiencies in freight spend, warehouse utilization, carrier performance, and routing to systematically reduce costs while improving service levels.

Learn more about the predictive algorithms powering these capabilities in Most Common AI Algorithms Used for Route Planning and Demand Forecasting.

Real-World Example: Preventing Disruption Before It Strikes

Consider a shipment of automotive parts from Shanghai to Detroit, scheduled to arrive at the Los Angeles port in five days. Traditional systems show the shipment is on schedule—everything appears fine.

But an AI-powered control tower detects what humans miss:

- Port congestion in Los Angeles is worsening, with current delays averaging 5-7 days

- Weather patterns suggest continued deterioration

- The Seattle port has 40% lower congestion with available berth capacity

The system's automated response:

- Instantly recommends rerouting through Seattle

- Calculates the cost-benefit analysis (2-day faster delivery, $800 additional cost vs. $15,000 production line shutdown cost)

- Alerts the warehouse team to adjust receiving schedules

- Updates customer with revised but earlier delivery timeline

Without the AI control tower, teams would discover the delay only after the shipment arrived—too late for corrective action, resulting in production shutdowns and customer penalties.

This proactive intelligence mirrors the predictive capabilities detailed in How Predictive Analytics Works for Logistics.

Core Benefits of AI-Powered Control Towers

End-to-End Supply Chain Visibility

Complete transparency across suppliers, manufacturers, warehouses, carriers, and 3PLs enables proactive management that reduces risks and costs.

Predictive Analytics for Smarter Decisions

Aggregating and analyzing data through AI leads to better forecasting, automated decision-making, and self-correction—resulting in more efficient operations and less waste.

Greater Supply Chain Agility

Agile supply chains pivot when disruptions occur, creating better customer experiences, faster response times, and overall efficiency gains.

Enhanced Collaboration

Connecting partners, suppliers, and logistics providers facilitates cross-organizational collaboration, leading to faster issue resolution, lower costs, and higher satisfaction.

Optimized Inventory Levels

Visibility across the entire network ensures companies have what they need, where they need it, when they need it—increasing turnover while reducing stockouts.

For insights into how control towers leverage diverse data sources, read What Kind of Data is Needed to Train an Effective AI Model for Supply Chain Optimization?.

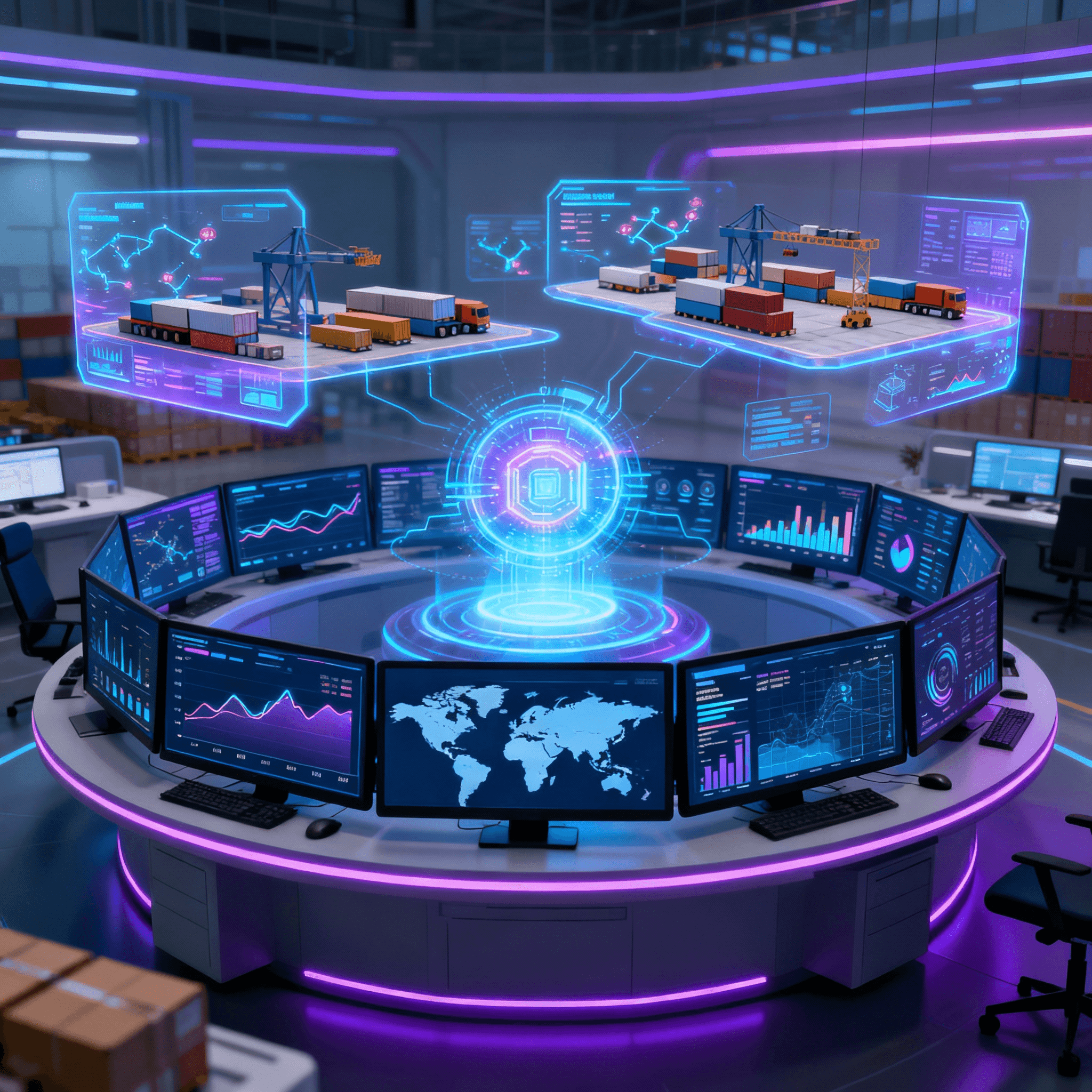

How debales.ai Powers Intelligent Control Tower Capabilities

debales.ai's AI platform delivers control tower intelligence tailored for logistics operations:

Unified Visibility: Real-time integration across TMS, WMS, ERP, and carrier systems providing single-source truth

Predictive Intelligence: Machine learning models forecasting disruptions, delays, and demand fluctuations

Automated Communication: AI agents coordinating with customers, carriers, and warehouse teams automatically

Dynamic Optimization: Continuous analysis identifying cost savings and efficiency improvements

Explainable AI: Transparent reasoning showing why recommendations are made and what factors drive predictions

Our platform combines the visual intelligence of computer vision, the communication capabilities of natural language processing, and the strategic foresight of digital twin simulation.

The Future of AI-Powered Control Towers

Next-generation control towers will evolve from decision support tools to autonomous command centers:

Autonomous Decision-Making: AI dynamically reroutes shipments, optimizes sourcing, and resolves bottlenecks without human intervention

Digital Twin Integration: Advanced simulations testing scenarios and improving resilience planning

Hyperautomation & IoT: Sensors and robotics delivering faster insights and automated actions

Sustainability Monitoring: Tracking carbon footprints, ethical sourcing, and ESG compliance

Edge Computing: Real-time processing at data sources for instant response

These capabilities represent the operational model described in A Simple Analogy for How AI Optimizes a Supply Chain.

Implementing an AI-Powered Control Tower

Successful implementation follows a structured approach:

Assess Current Gaps: Identify inefficiencies in tracking, carrier selection, cost management, and risk prediction

Integrate Existing Systems: Ensure ERP, TMS, and WMS sync with AI analytics for real-time data flow

Configure Predictive Alerts: Implement AI-driven notifications for delays, performance issues, and cost fluctuations

Enable Automated Workflows: Move from AI-assisted to autonomous decision-making where appropriate

Measure and Optimize: Track KPIs demonstrating ROI and continuously refine algorithms

The Bottom Line: From Visibility to Intelligence

AI-powered control towers represent the difference between knowing what happened and predicting what will happen—between reacting to problems and preventing them entirely.

Organizations still relying on manual tracking and disconnected systems face rising costs, frequent delays, and reactive firefighting, while competitors leveraging AI-powered control towers achieve:

- 15-20% reduction in freight costs

- 30% improvement in on-time delivery

- 10-20% gains in labor productivity

- 3-5% reduction in overall logistics costs

- Up to 1% increase in revenue through better service

Ready to transform your supply chain from reactive monitoring to intelligent orchestration?

Discover how debales.ai's AI-powered control tower delivers real-time visibility, predictive intelligence, and autonomous optimization—turning logistics complexity into competitive advantage.

Book a demo with debales.ai today and experience the future of supply chain command and control.