The $500K Problem Freight Ops Pretends Isn’t Real (Until It Hits Margin)

Tuesday, 13 Jan 2026

|

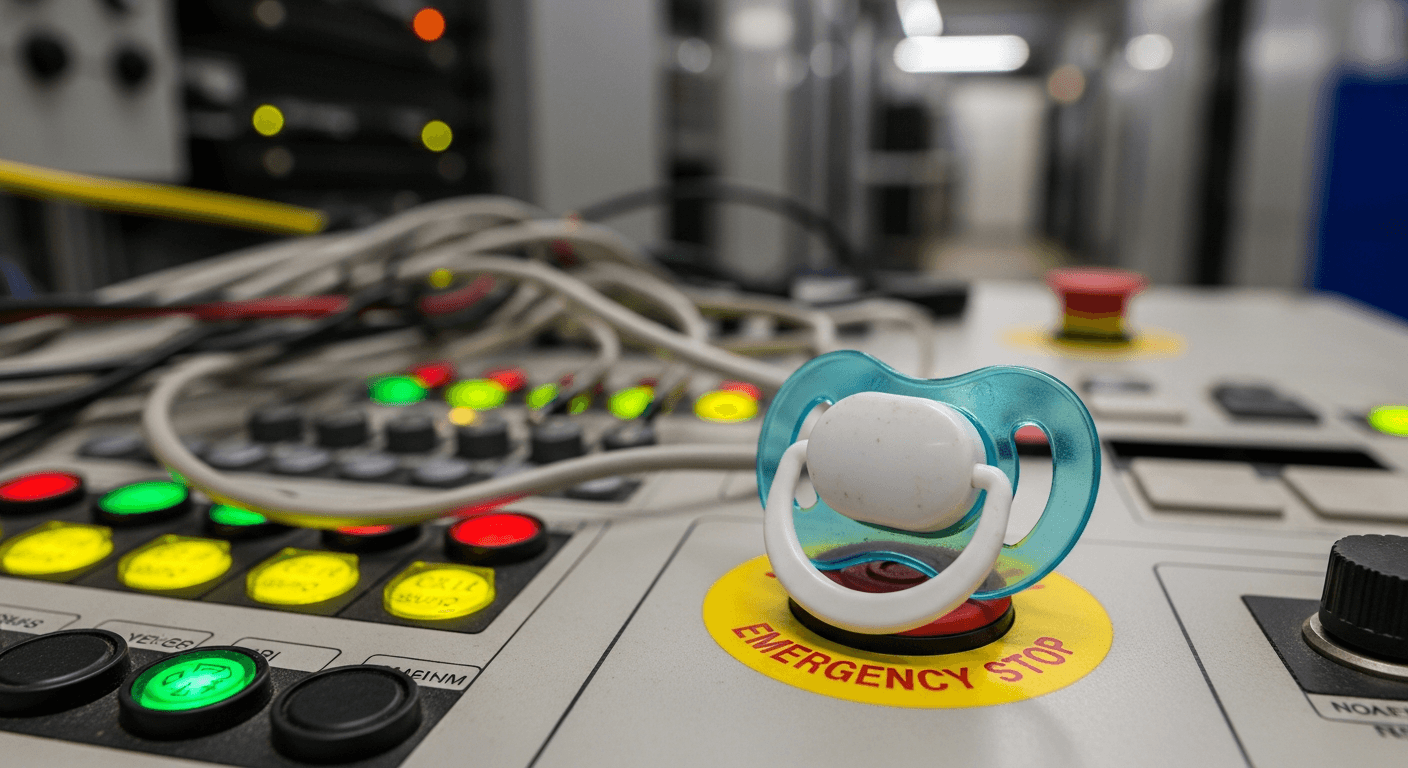

The $500K Problem Freight Ops Pretends Isn’t Real (Until It Hits Margin)

Most freight ops teams don’t wake up and say, “Let’s waste money today.”

It happens the respectable way: through professionalism, hustle, and a thousand tiny tasks done “just to keep things moving.”

• A dispatcher follows up on a quote that should’ve been nudged automatically• Someone rebuilds the same packet of lane notes for the third time this week• A customer email gets answered from memory because the data is spread across five places• A document gets reworked because the first version was missing one field that lives… somewhere else

None of it looks like failure. It looks like work.

And that’s why the $500K problem hides so well: it doesn’t show up as a single big mistake. It shows up as normal operations, until you zoom out and realize it’s quietly eating your margin.

This post breaks down what the “$500K problem” actually is, how it forms inside competent teams, and how to spot it before it becomes your default operating cost.

What is the “$500K problem,” really?

Let’s be precise: the $500K is not a universal number. It’s a pattern, a common annual margin leak that shows up when freight operations runs on manual glue.

The leak usually comes from a mix of:

• Time tax labor: high value people doing low value coordination• Opportunity loss: quotes not followed up, renewals missed, upsells delayed• Error and rework: corrections, escalations, chargebacks, avoidable accessorial disputes• Service degradation: slower response times that reduce win rate and retention• Decision latency: “we’ll get back to you” becomes your brand experience

The hard part: none of these look like a $500K line item. They look like “ops being ops.”

So instead of arguing about a number, let’s build it from first principles.

The quiet math behind a very loud margin hit

Here’s a conservative way the $500K shows up without anyone noticing.

1) The micro task tax

Pick a typical freight ops day:

• triaging inbound quote requests• collecting missing details• hunting for lane history• coordinating handoffs sales to ops to carriers to customer• checking doc status• follow ups• exception handling• status updates• “can you resend that?”

If 10 people each lose 45 minutes per day to avoidable back and forth (not “work,” but work about work), that’s:

• 10 people• 0.75 hours per day• about 240 working days per year• equals 1,800 hours per year

Now translate that to cost. Fully loaded costs vary by region and role, so use your own numbers. But even at a modest fully loaded rate, you’re staring at a six figure tax, before we touch lost revenue.

And here’s the kicker: that 45 minutes often feels like nothing because it’s distributed across 30 tiny interruptions.

2) The follow up gap (the revenue leak that feels like “market”)

Freight teams rarely lose business because the market is “hard.” They lose business because:

• response is late• follow up is inconsistent• quote context is missing• a second option wasn’t offered• the customer had to repeat themselves• exceptions took priority over pipeline

Even small changes in response speed and consistency can change outcomes, because shippers don’t reward effort, they reward reliable execution.

3) The exception spiral (when your best people become firefighters)

Exceptions aren’t the issue. Freight will always have exceptions.

The issue is exception handling that isn’t designed. It’s improvised.

That means:

• exceptions steal attention from standard flow• standard flow slows down• delays create more exceptions• senior people get pulled into routine triage• throughput drops, pressure rises, quality slips

This is how “busy” becomes a permanent state.

Why competent teams normalize it

Freight ops is full of sharp people. If the leak is so obvious, why does it persist?

Because it comes disguised as good behavior:

• “I’ll just handle it.”• “I know where that info is.”• “It’s faster if I do it myself.”• “We can’t risk automation messing it up.”• “We’ll fix process later, today we need to move loads.”

This creates a culture where heroics replace systems.

Heroics are admirable. They’re also expensive.

And here’s the trap: if your team is capable enough, you can operate like this for a long time. You’ll still hit numbers, until volume shifts, headcount changes, or one key person leaves, and suddenly the leak becomes visible as margin pain.

The three symptoms that tell you the $500K problem is already in your building

1) Your “source of truth” is a person

If someone leaving would cause chaos because they “know how things work,” you’re not running a system. You’re running tribal memory.

2) Your tools track work, but don’t run work

CRMs, TMS, inboxes, spreadsheets, great at holding information. Terrible at owning execution.

So humans become the integrations:

• copy and paste between systems• reminders• follow up logic• exceptions routing• “did we do the thing?” checks

3) You have meetings that exist to compensate for missing workflow ownership

If you have recurring meetings to answer:

• “Where are we on this?”• “Who owns that?”• “Did the customer get the doc?”• “What’s the latest rate?”

That’s not coordination. That’s a symptom of a workflow gap.

A practical way to estimate your leak in 30 minutes

No complicated dashboards required. Do this with your team leads.

Step 1: List your recurring manual workflows

Examples:

• quote to follow up sequence• quote to revise to confirm to book• doc collection and validation• appointment scheduling• exception triage• status updates and customer comms• accessorial documentation• carrier onboarding and compliance tasks

Step 2: Identify “work about work” moments

For each workflow, mark where time goes to:

• chasing missing information• reformatting details• reconciling systems• reminding people• rework due to incomplete context

Step 3: Apply a conservative time cost

Even 15 minutes saved per workflow per day across a small team becomes huge annually.

The point isn’t perfect accounting. The point is to make the invisible visible.

A quick exercise you can use today

If you want a clearer picture fast, map one workflow start to finish (for example: quote to follow up to book) and write down every step where a human has to “remember,” “check,” or “nudge.” That list is your opportunity backlog.

If you’d like, we can walk through that workflow with you and show what it looks like when execution is owned by an intelligent workflow (not just tracked in tools). Book a working session here: /bookdemo

“But we already have automation…”

Many teams do. The issue is what kind.

Rules based automation helps, until reality happens

Rules are great for:

• “If X, then email Y”• “If status changes, send alert”

But freight isn’t only status changes. It’s:

• incomplete inputs• ambiguous requests• exceptions• multiple stakeholders• shifting constraints• messy documents• “do it anyway” urgency

So rules create a new kind of work:

• managing alerts• handling edge cases• maintaining brittle logic• “why didn’t it fire?” investigations

The result: you automate the easy 30%, then your team still manually handles the 70% that determines margin and service.

What actually fixes the leak

Not “more tools.” Not “more dashboards.”

Workflow ownership.

The big change comes when execution is shared between humans and systems in a way that:

• captures context once• routes tasks automatically• handles follow ups consistently• escalates only true exceptions• reduces coordination overhead• keeps work moving without heroics

When that happens, your ops team stops being a bottleneck and starts being a throughput engine.

What mature ops teams do differently

Across high performing operations teams (in freight and beyond), you see the same patterns:

• They design around exceptions instead of hoping exceptions won’t happen• They standardize data capture early so downstream work doesn’t fragment• They build workflows that don’t rely on “remembering.”• They measure flow metrics (response time, time to book, time to resolution), not just volume metrics• They protect focus by reducing interruptions and rework loops

None of that is glamorous. It’s also exactly how you get margin back.

The bottom line: you don’t need a bigger team, you need less invisible work

The $500K problem is what happens when manual glue becomes the operating system.

It’s not one broken tool.It’s not one bad hire.It’s not one department “not doing their part.”

It’s the accumulation of tiny, avoidable actions that quietly turn margin into motion.

When you fix it, the wins compound:

• faster response times• higher quote to book consistency• fewer errors and escalations• improved customer experience• less burnout• more capacity without more headcount

And you don’t have to “transform everything” to start. You start with one workflow, one pain point, one measurable outcome.

Ready to find your leak and fix it

Want to see where the $500K leak is hiding in your operation, and what it looks like when execution is owned by an intelligent workflow?

Book a demo here: